Bent steel tube automatic flaw detection system based on ultrasonic detection

An ultrasonic and ultrasonic probe technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc. Problems such as bending pipe production requirements and low detection efficiency, to achieve the effect of simple motion control, improved ultrasonic detection efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and embodiments.

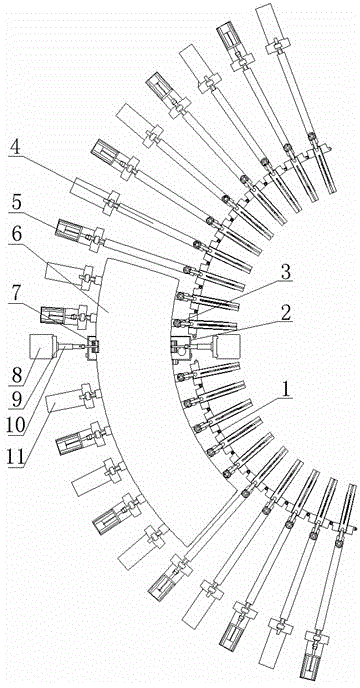

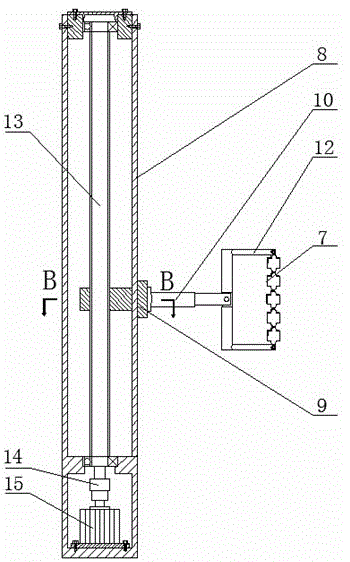

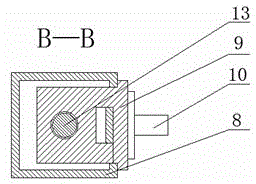

[0027] Combine figure 1 As shown, the present invention adopts a method in which the elbow 6 to be tested is fed along its axial direction during ultrasonic testing of the elbow, and the chain-type ultrasonic probe holder 7 moves in the circumferential direction on the surface of the elbow. The system includes a elbow feeding mechanism. It has the same structure as two sets of ultrasonic testing mechanism for bent pipes. The elbow feeding mechanism includes a set of drive cages composed of a drive roller 4, a support roller 3, a motor mounting frame 11, a support roller mounting frame 21, a support roller guide rail frame 23 and a drive roller mounting frame 24; the two sets have the same structure The ultrasonic testing mechanisms for bent pipes all include a vertical sliding guide frame 8, a detection slider 9, a trapezoidal screw 13, a screw motor coupling 14, a detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com