Triggered-stroke actuator provided with a gas discharge device

A technology for gas generators and actuators, applied in fluid pressure actuators, pyrotechnic actuators, transportation and packaging, etc., can solve the problems of high cost and difficult implementation of leakage ports, and achieve cheap and easy manufacturing , easily reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

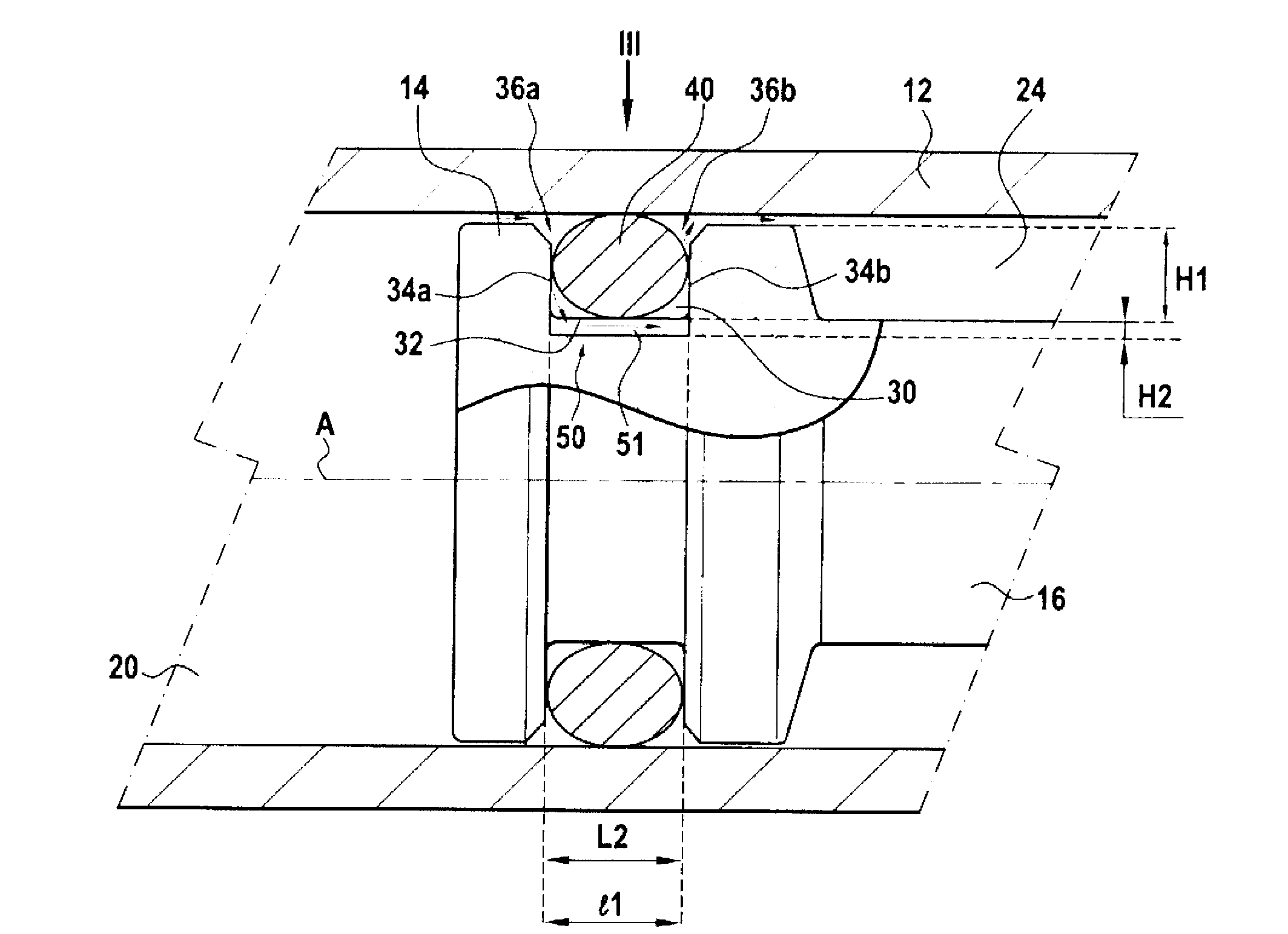

[0087] According to this third embodiment, and as in the previous embodiments, the groove 230 formed at the periphery of the piston 14 is intended to receive the sealing joint 40 . In the example considered in the figures, the groove 230 has a bottom 232 and two side walls 234a and 234b.

[0088] like Figure 13 As shown, the recess 230 houses within it elements for forming a protrusion 280 which locally reduces the cross-section available within this recess for sealing the joint 40 .

[0089] The size of the additional element, especially its width l3 (see Figure 15 ) is chosen such that the compressibility of the joint 40 is only changed locally.

[0090] In this example, the additional element 280 is a strip folded into a U-shape to fit the shape of the groove 230 and to be able to be located in the groove 230 under the sealing joint 40 so that the base 282 of the U-shape rests against the groove. The bottom 232 of the groove 230 , and its wings 284 a and 284 b lean aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com