Cutting temperature monitoring device for high-speed drilling process

A cutting temperature and monitoring device technology, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of complex experiment settings, practical difficulty of semi-manual thermocouple temperature measurement, inability to obtain tool life and hole processing quality Cutting temperature and other issues, to achieve the effect of good dynamic balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

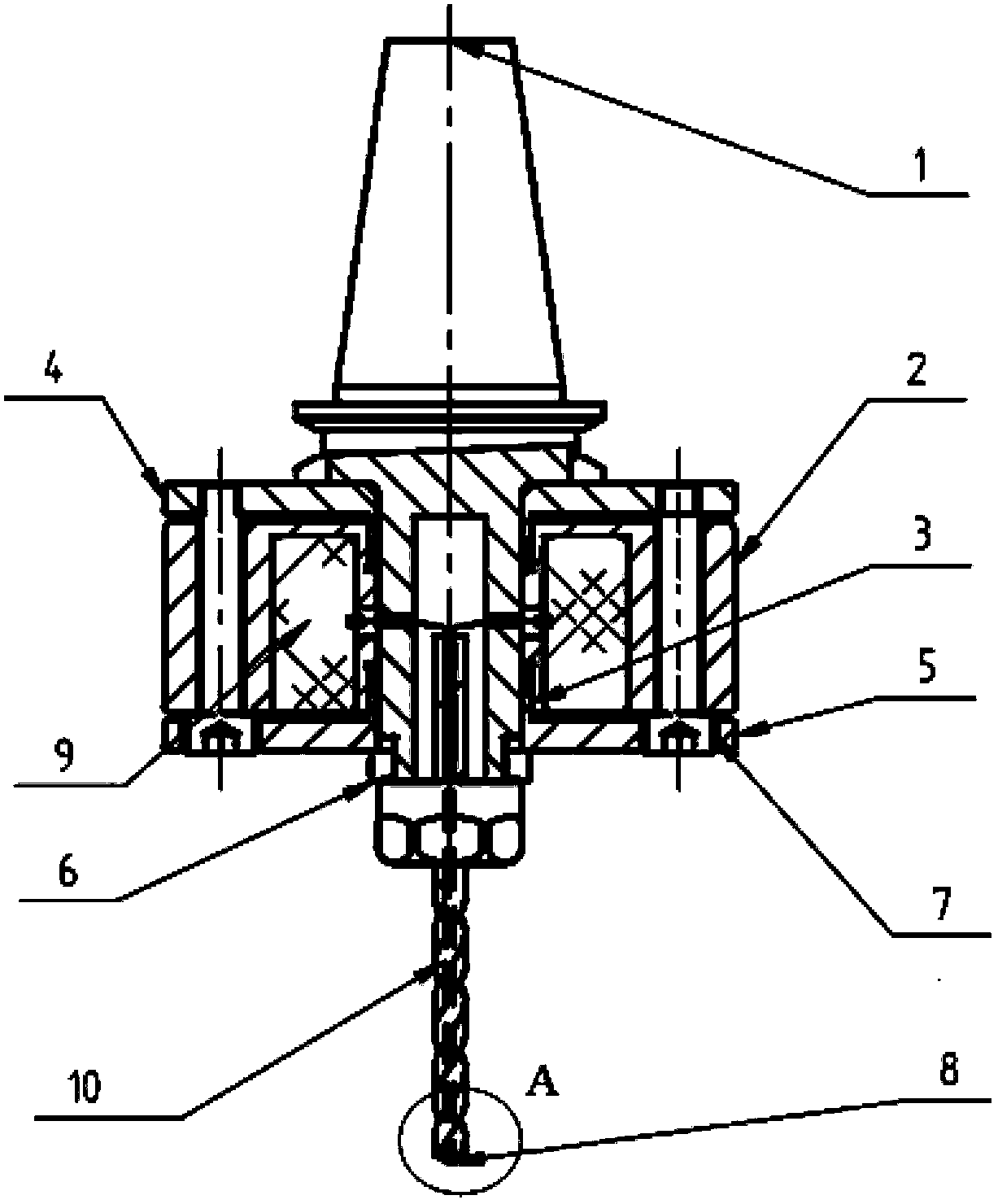

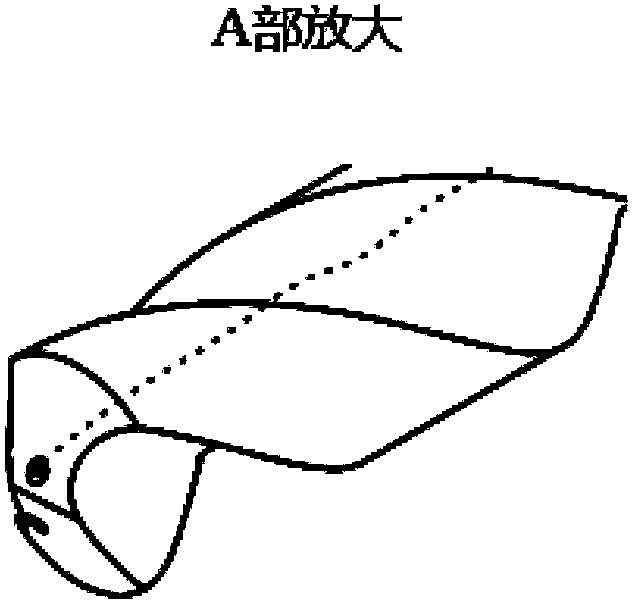

[0017] The present invention is a device for long-term and continuously changing cutting temperature monitoring in a high-speed drilling system. It is based on the principle of artificial thermocouple temperature measurement, and the tool life cycle is realized by setting the experimental device on the rotating drilling tool once. The long-term and continuous cutting temperature monitoring in the drilling tool is specifically to use the internal cooling hole of the drilling tool to embed the standard thermocouple, and then realize the long-term and continuous cutting temperature collection through the storage type thermoelectric potential acquisition module. The whole set of monitoring device maintains the high-speed performance of the device during rotation through dynamic balance design, and ensures its long-term and continuous monitoring data recording.

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention is described in detail, prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com