Full-automatic template sewing machine

A sewing machine, fully automatic technology, applied in the field of sewing machines, can solve the problems of the machine head cannot be moved, the production efficiency is difficult to improve, and the time consuming is long, and the effect of reducing the defective quality rate, shortening the production time, and reducing the degree of dependence is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0019] from Figure 1 to Figure 4 Shown embodiment of the present invention can know:

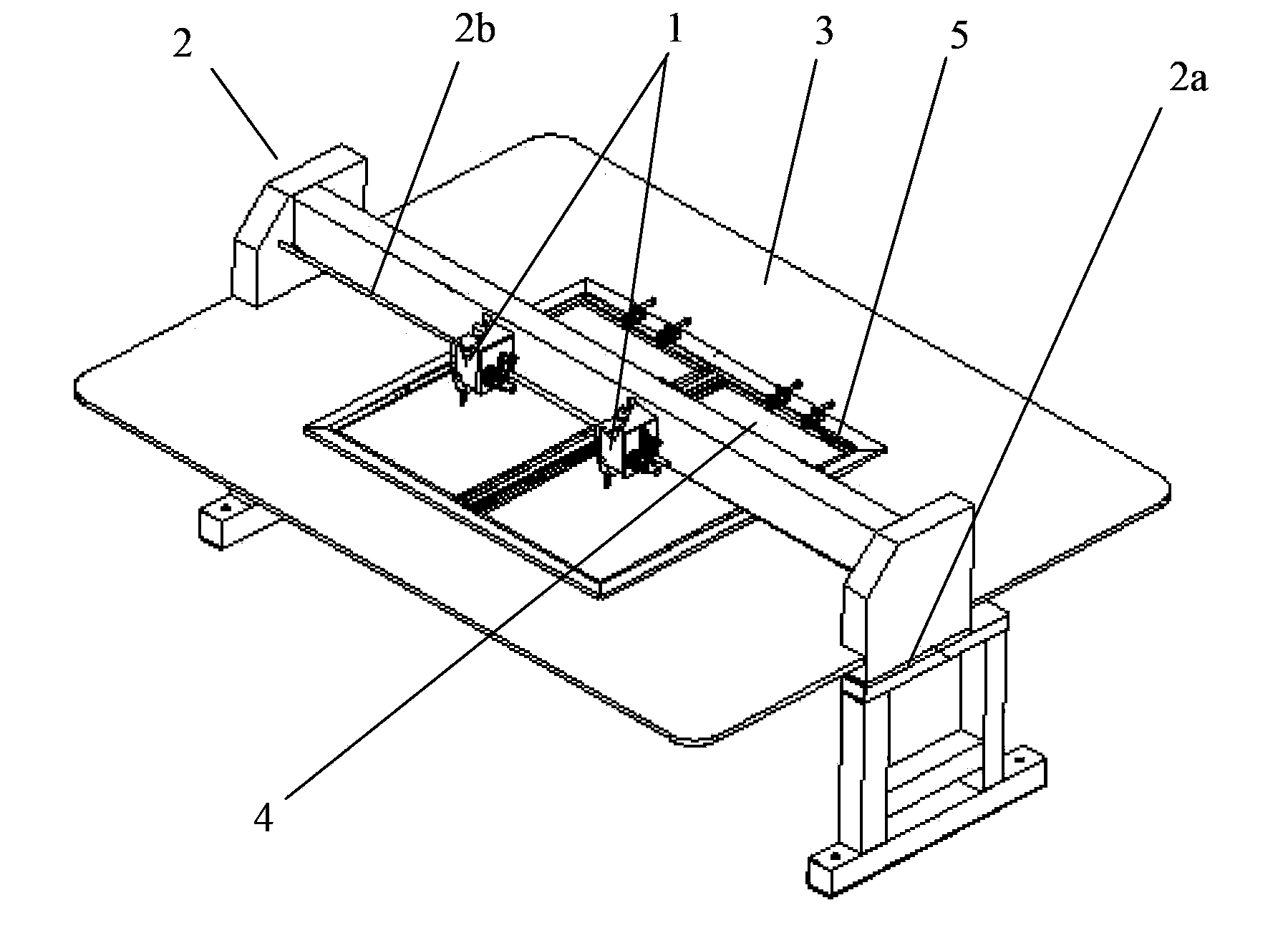

[0020] The automatic template sewing machine of the present invention comprises a sewing machine head 1, a frame 2, a platen 3, a template 4, an automatic clamping template device 5 equipped with the template 4 installed on the platen 3 and driving the The X, Y direction driving mechanism that the automatic clamping formwork device 5 moves on the said platen 3; A main shaft 2b mounted on the frame legs 2a, located on one side of the beam and parallel to the beam; the platform 3 is installed between the legs 2a of the frame 2, under the beam; Two of said sewing machine heads 1 are mounted on said main shaft 2b along which said sewing machine heads 1 are movable.

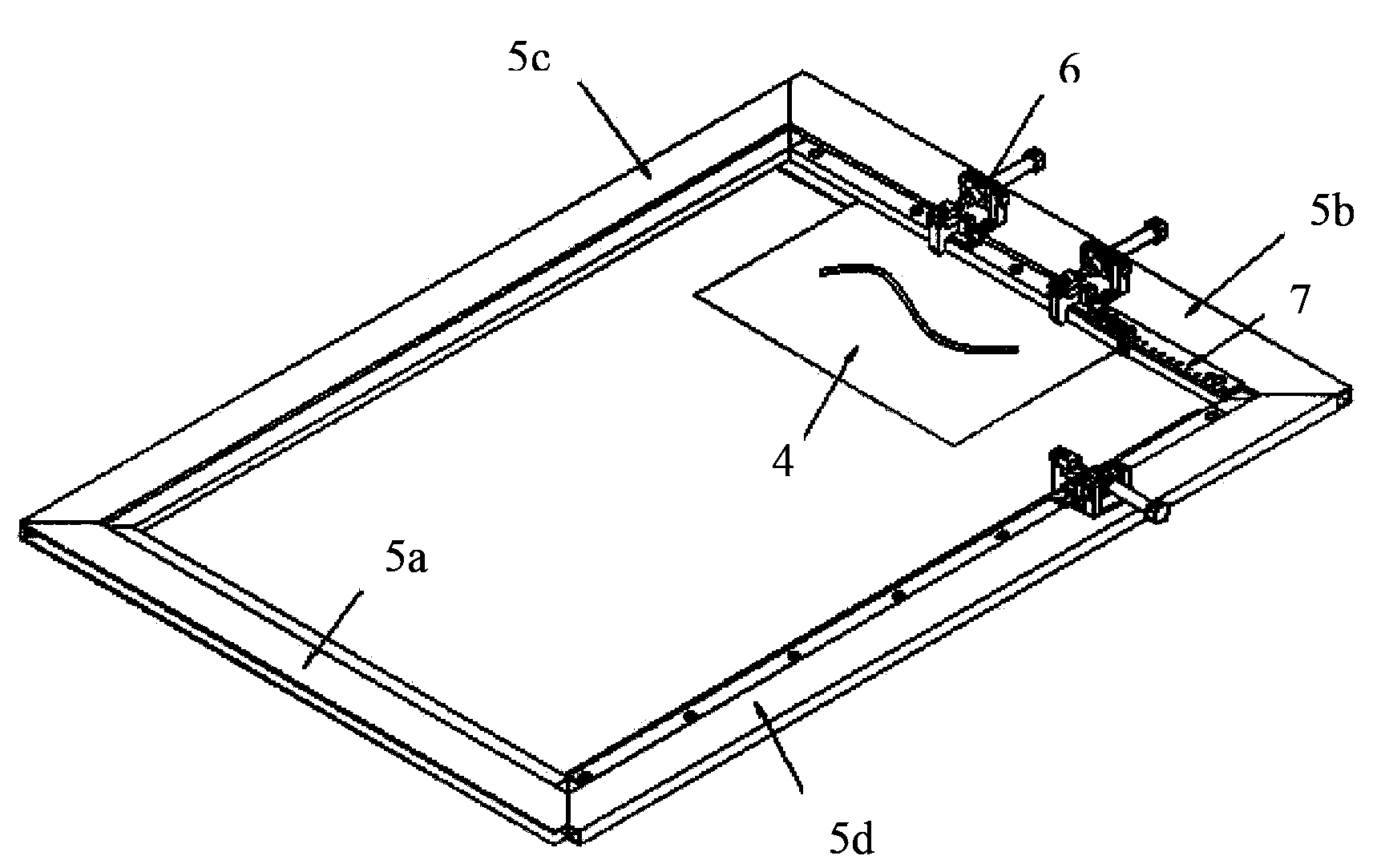

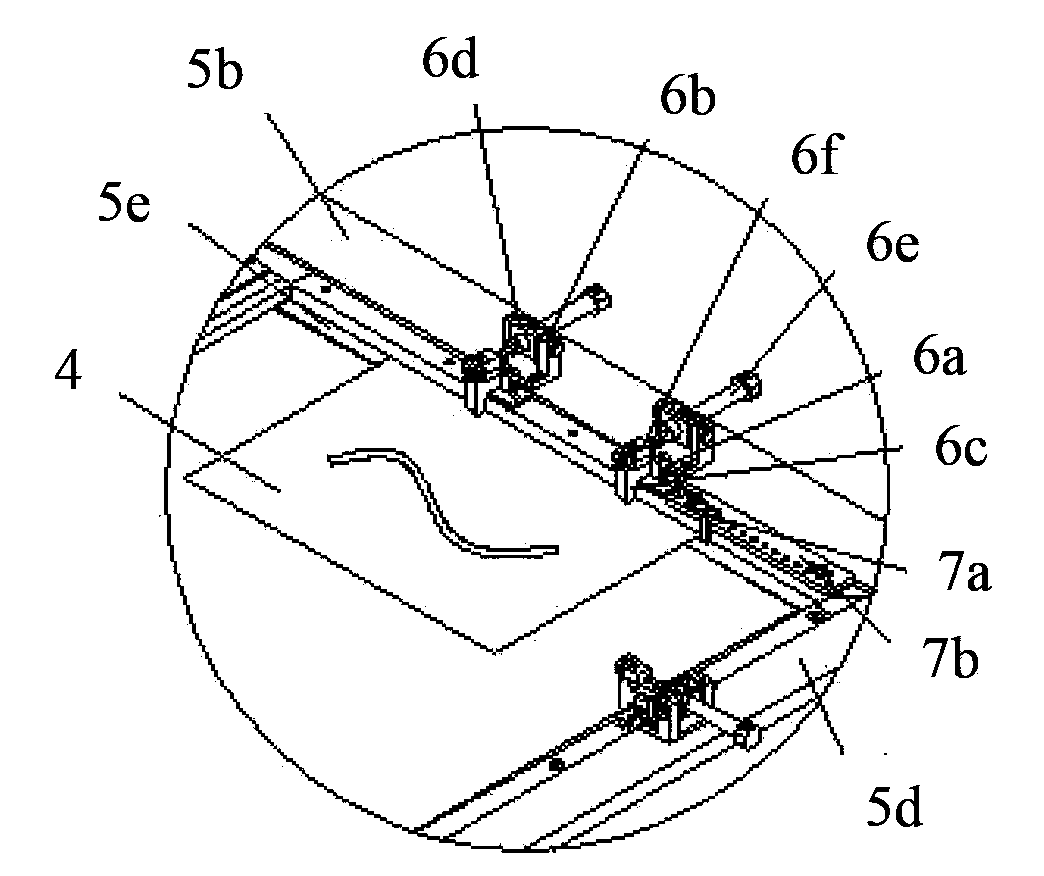

[0021] Such as figure 2 As shown, the automatic clamping formwork device 5 includes a rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com