Method for forming thin-walled molded product

A thin-formed product and process technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve problems such as unavailability, deterioration of optical properties, increase in weight, etc., achieve smooth compression process, prevent residual residual stress, and alleviate Effects of deviations in pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

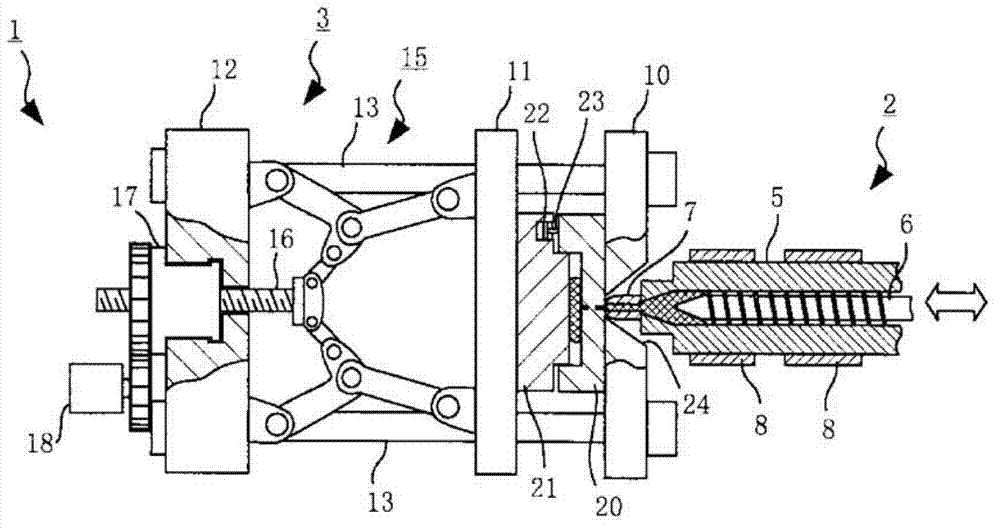

[0029] The molding method of the thin molded article of this embodiment can be performed by a conventionally known injection molding machine. In this embodiment, a method of molding a medium-sized or larger light guide plate for liquid crystal with the electric injection molding machine 1 will be described, but the electric injection molding machine 1 will be schematically described. Such as figure 1 As shown, the electric injection molding machine 1 is also composed of an injection device 2 and a mold clamping device 3 as is conventionally known. The injection device 2 is composed of a heating cylinder 5 and a screw 6 provided in the heating cylinder 5 , and an injection nozzle 7 is provided at the front end of the heating cylinder 5 . A band heater 8 is wound around the outer peripheral surface of the heating cylinder 5 , and a hopper for supplying a resin material into the heating cylinder 5 is provided near the rear end. figure 1 The hopper is not shown. The screw 6 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com