Device for measuring revolution and revolving speed of rotary shafts

A technology of measuring device and rotating shaft, which is applied in the field of measurement, can solve the problems of wasting equipment disassembly, reinstallation and debugging time, affecting production, etc., and achieve the effect of stable work, convenient disassembly and installation, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

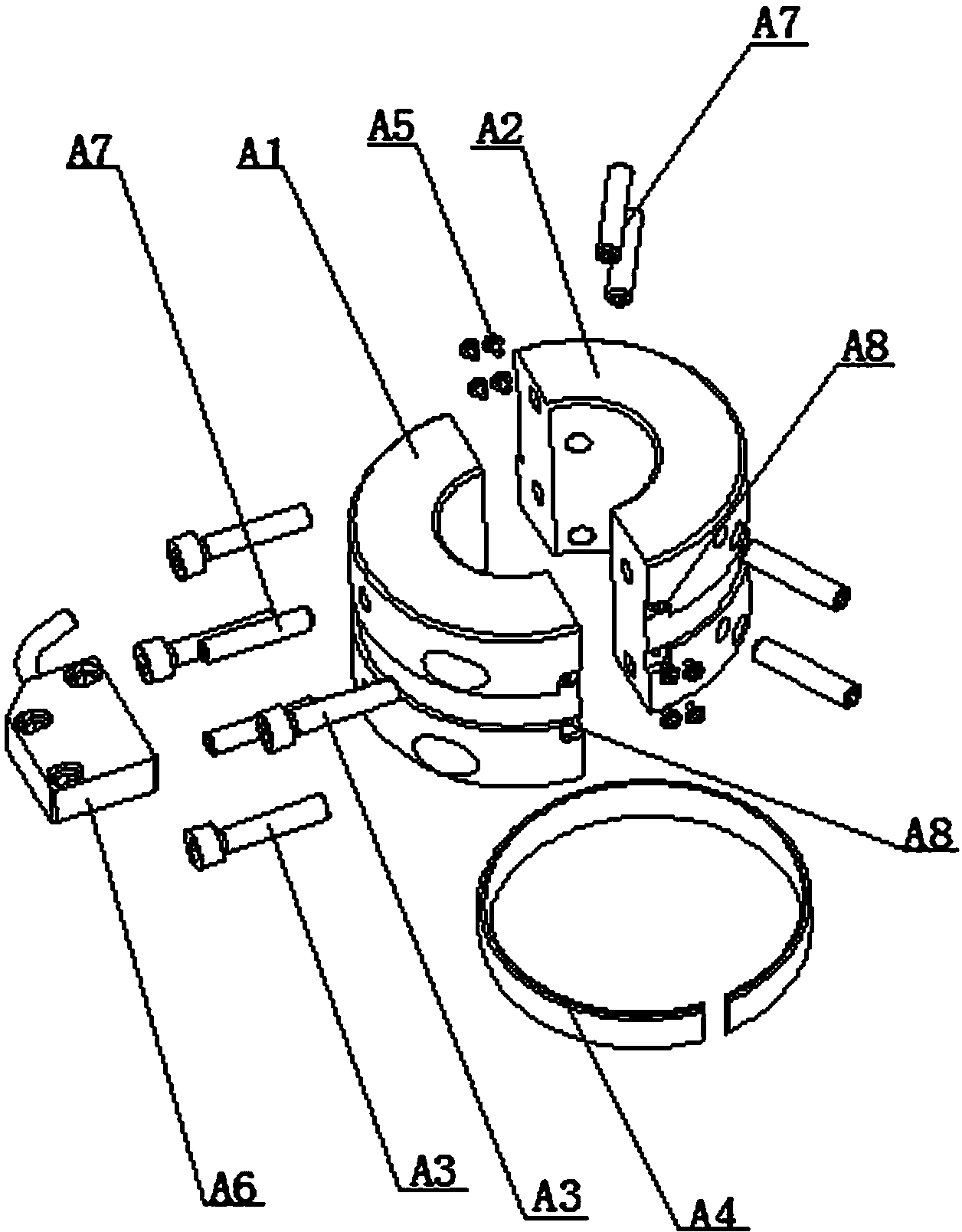

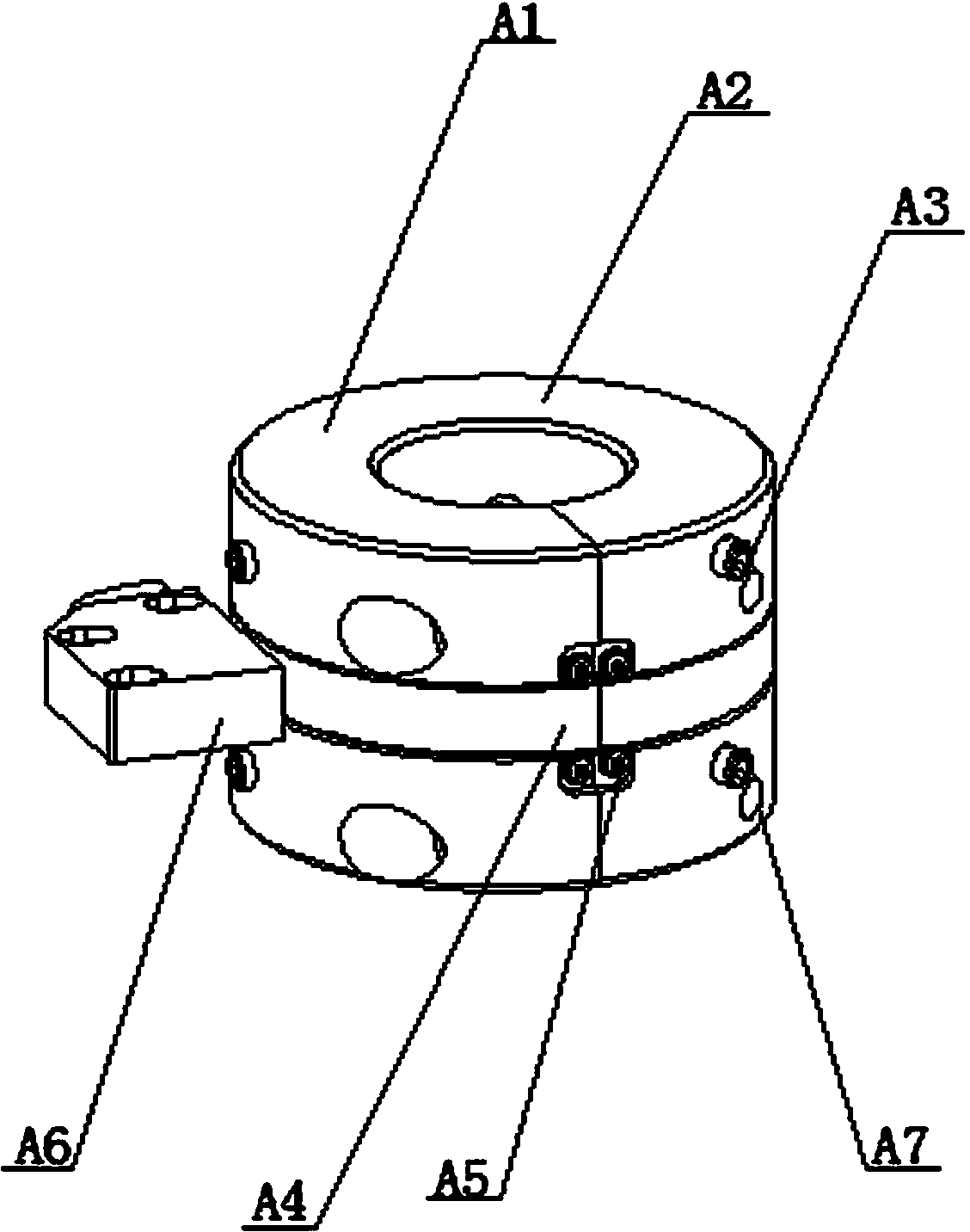

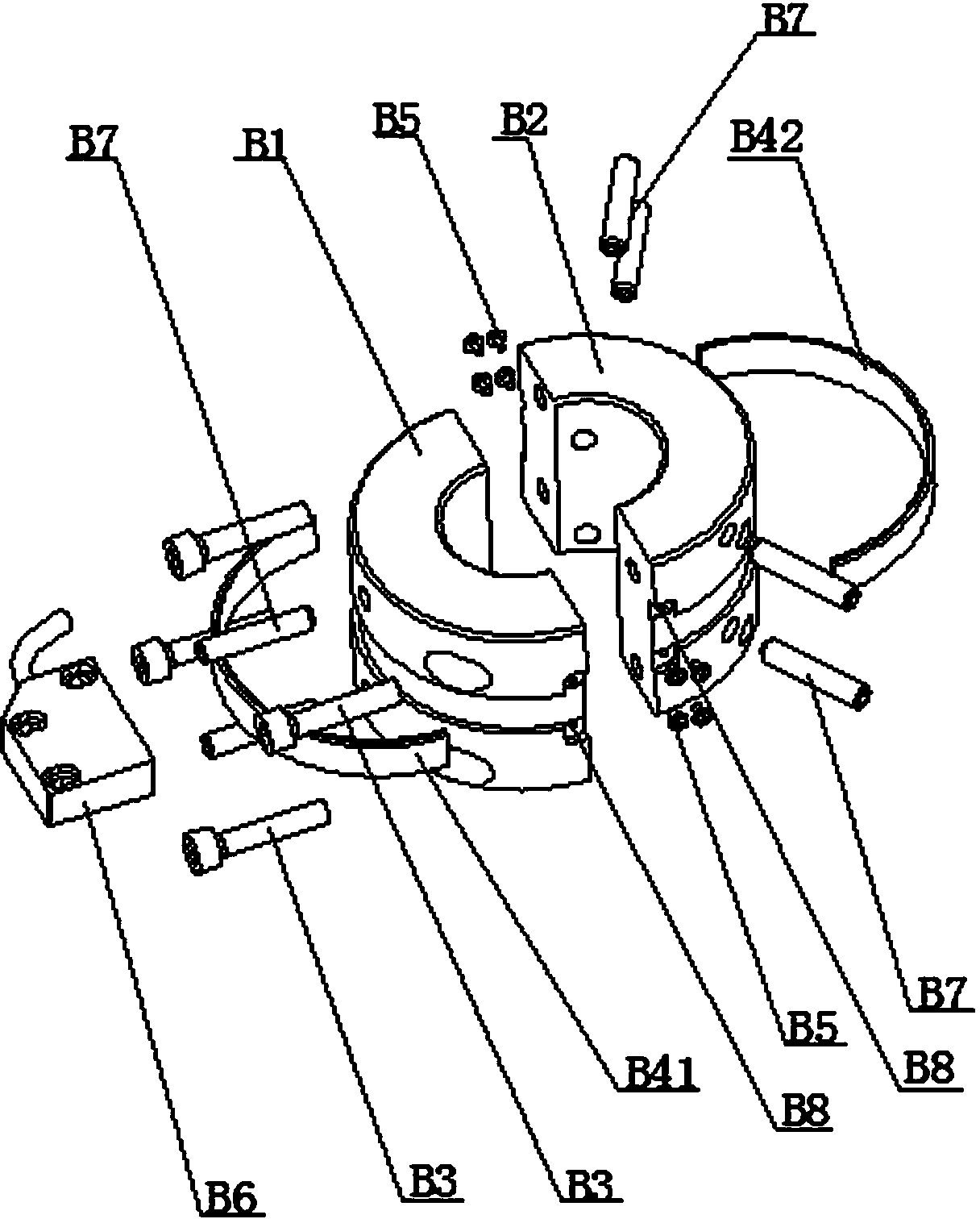

[0027] see Figure 1-2 , the present invention provides the first embodiment of the measuring device for the number of revolutions of the rotating shaft and the rotating speed, including the first semi-circular ring A1, the second semi-circular ring A2 and a plurality of locking bolts A3; the first semi-circular ring A1 passes through multiple A locking bolt A3 is fixedly connected with the second semicircular ring A2 to form a circular ring; the measuring device also includes a magnetic tape ring A4, a plurality of magnetic tape ring screws A5, a magnetic sensor A6 for inductive magnetic signals on the magnetic tape ring A4, and A plurality of concentricity adjustment screws A7 for adjusting the radial runout of the ring; the tape ring A4 is fixed and pasted on the outer circumference of the ring by a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com