Slide switch closing tool

A sliding sleeve switch and tool closing technology, which is applied in wellbore/well components, sealing/packing, earthwork drilling and production, etc., can solve the problems of on-site operation risks, short effective life, and failure of sand control operations, and achieve easy operation and Safe and reliable, prolonging service life, effective effect of sand control operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

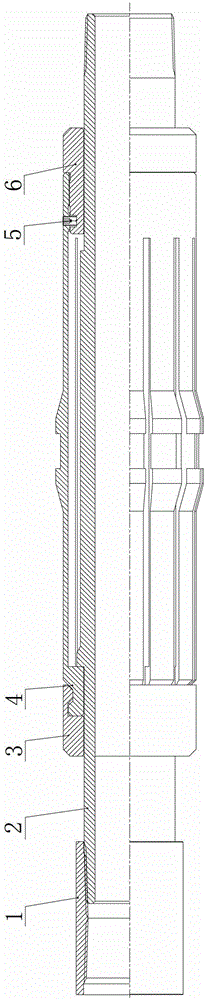

[0031] See figure 1 , A sliding sleeve switch tool, comprising a center tube 2, an upper connecting part and a lower connecting part are provided on the center tube, and an upper joint 3 and an elastic claw 4 are sleeved on the center tube,

[0032] A first annular inner flange is provided on the lower inner wall of the upper joint, and an inner annular groove is provided above the first annular inner flange;

[0033] The lower part of the elastic claw is annular, the middle and upper part are provided with a plurality of axial notches, and the upper part of the elastic claw is provided with an outer annular flange and a first outer annular recess that respectively cooperate with the first annular inner flange and the inner annular groove The groove is provided with a second outer annular groove in the middle of the elastic claw. The two side walls of the second outer annular groove are both circular planes perpendicular to the axis of the central tube. The backs of the two side wal...

Embodiment 2

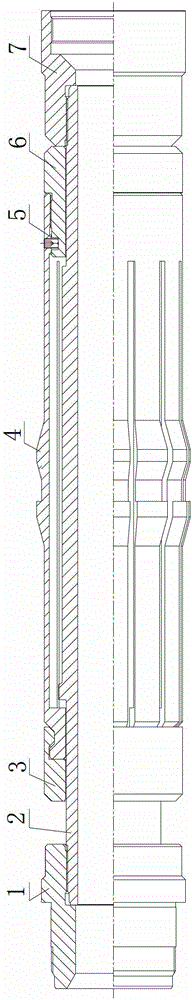

[0043] See figure 2 , A sliding sleeve closing tool, comprising a central tube 1, an upper connecting part and a lower connecting part are provided on the central tube, an upper joint 3 and an elastic claw 4 are sleeved on the central tube,

[0044] A first annular inner flange is provided on the lower inner wall of the upper joint, and an inner annular groove is provided above the first annular inner flange;

[0045] The lower part of the elastic claw 4 is annular, the middle and upper part are provided with a plurality of axial notches, and the upper part of the elastic claw is provided with an outer annular flange and a first outer annular flange which cooperate with the first annular inner flange and the inner annular groove respectively. The groove is provided with a second outer annular groove in the middle of the elastic claw, the upper side wall of the second outer annular groove is an annular plane perpendicular to the axis of the central tube, the lower side wall is a ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com