Thermally-sealing and spot-breaking device of bag making machine

A bag-making machine and point-breaking technology, which is applied in the direction of container manufacturing machinery, packaging, transportation and packaging, etc., can solve the problems of unsightly, skewed and point-broken lines, and inconsistency, so as to optimize the mechanical structure, realize precise positioning, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

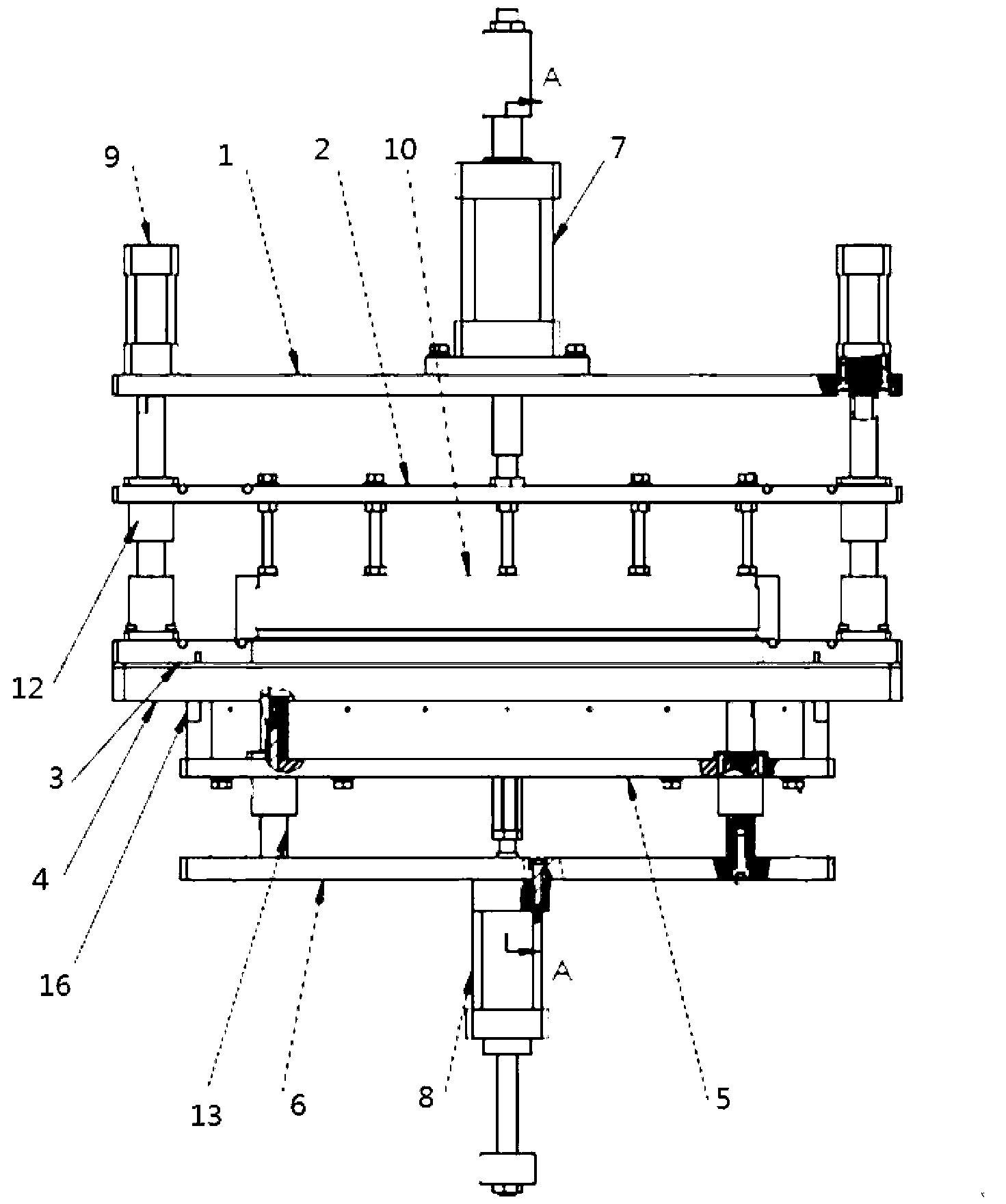

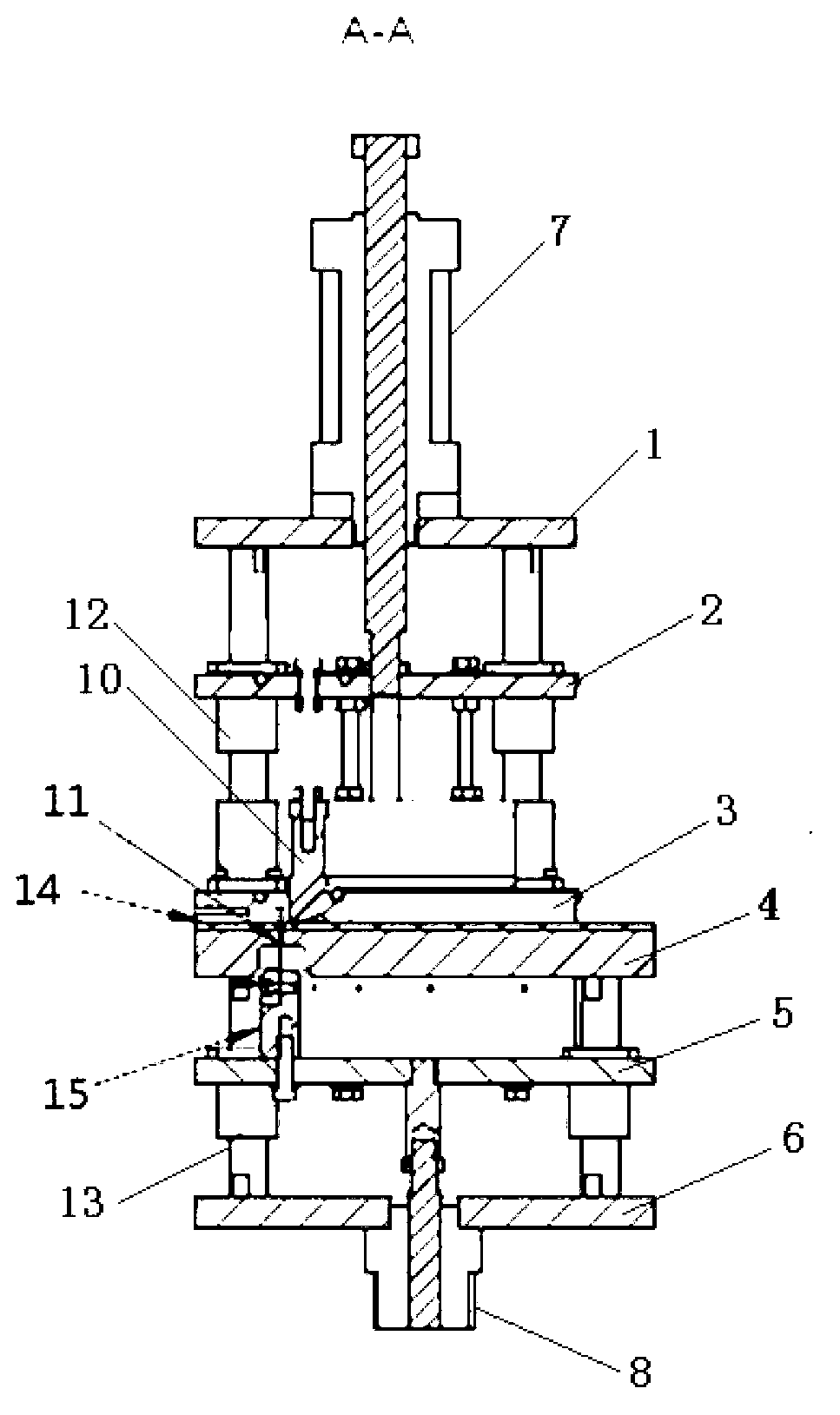

[0016] Example: refer to figure 1 , shown in 2, a kind of bag-making machine heat-sealing break-off device, comprises the upper fixed plate 1 that is arranged from top to bottom, upper movable plate 2, pressing plate 3, positioning plate 4, lower movable plate 5 and lower fixed plate 6, Upper and lower movable plate driving devices 7, 8 are fixed respectively on the upper and lower fixed plates 1, 6, and the upper and lower movable plate driving devices 7, 8 are connected respectively and drive the upper and lower movable plates 2, 5 to move up and down. The upper movable plate 2 is fixed with a heat-sealing knife 10 pointing to the positioning plate 4, and the lower movable plate 5 is fixed with a point breaking knife 11 pointing to the positioning plate 4, and the point breaking knife 11 corresponding to the below on the positioning plate 4 is provided with a The movable groove of the point-breaking knife 11 passes through, and the pressing plate 4 is connected to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com