Reclaimer machine

A technology of reclaimer and bucket wheel, which is applied in the direction of earth mover/shovel, open pit mining, earthwork drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

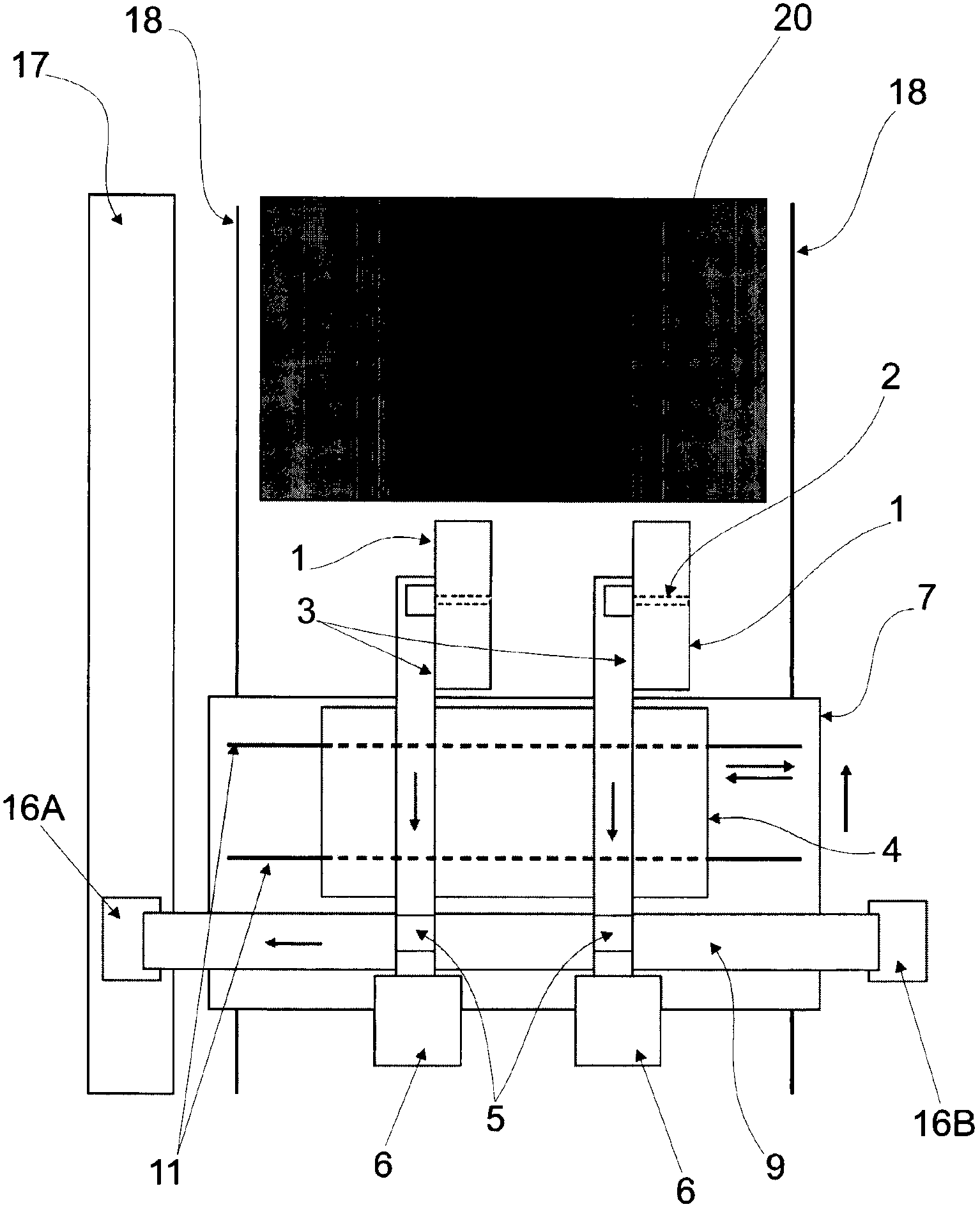

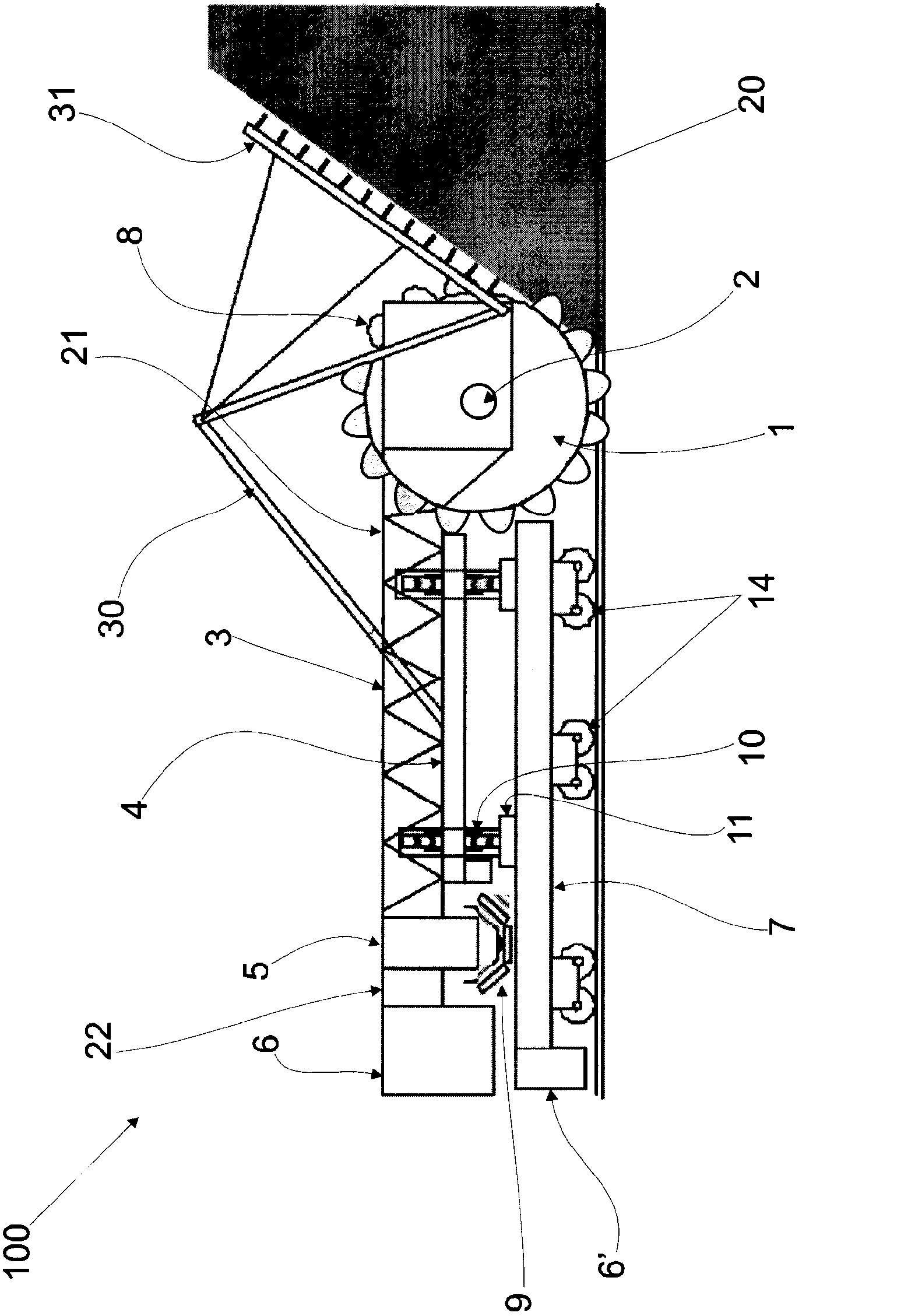

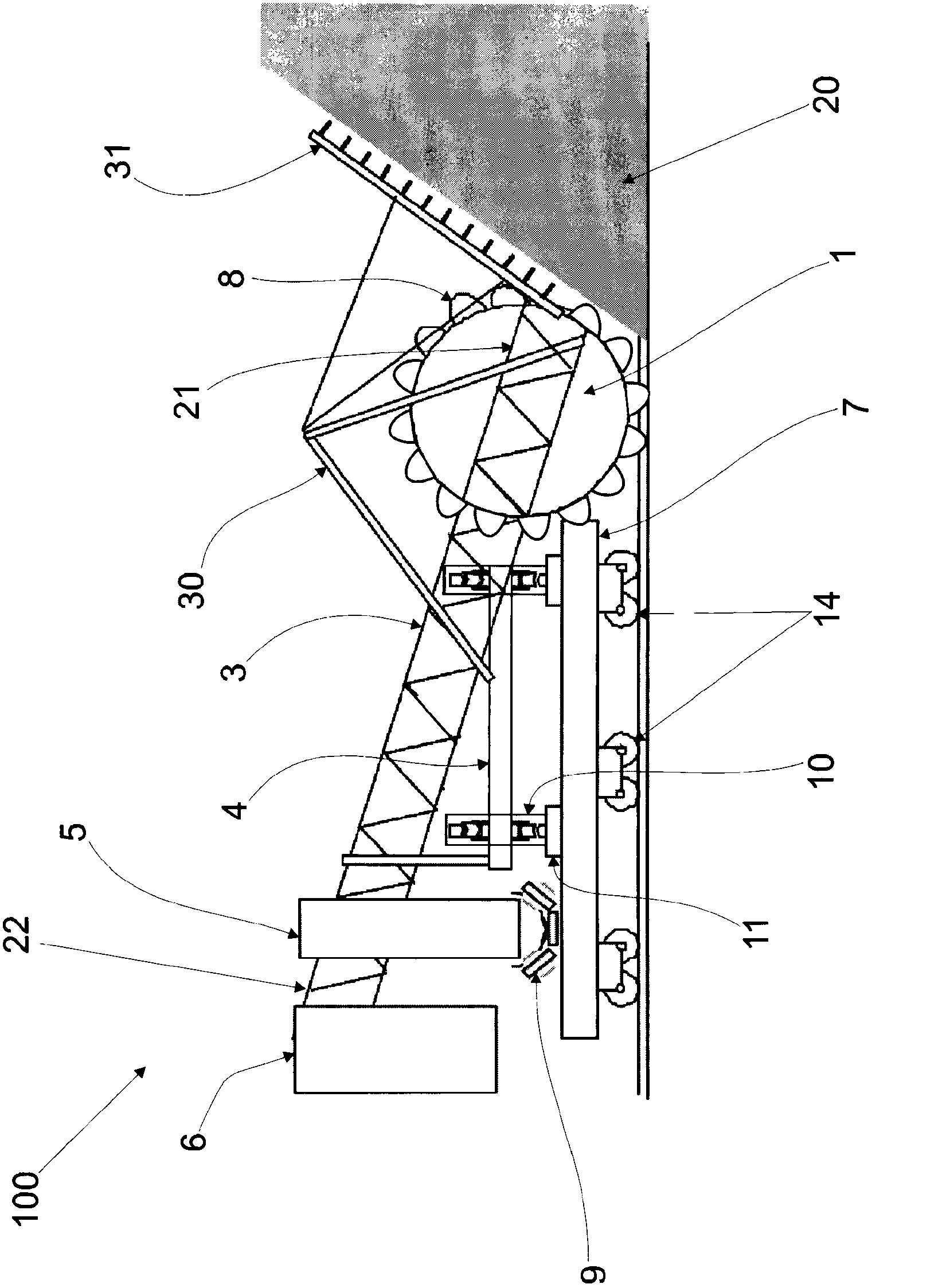

[0017] Based on the preferred embodiment and according to Figure 1 to Figure 3 , the reclaimer 100 includes a bucket wheel 1 that includes a set of buckets 8 rotating around an axis 2 driven by a motor and a reducer (not shown) or by a driving force (torque) such as from a hydraulic motor )drive. The bucket wheel 1 is connected to a conveyor belt structure 3 which supports the bucket wheel 1 and is also connected to a transfer chute 5 .

[0018] The rake support structure 30 is connected to the conveyor belt structure 3 supporting the counterweight 6 . This structure 30 comprises a rake 31 with a breaker directed towards the pile 20 or pile, with the purpose of breaking up the pile 20 . All these structural connections can change according to the calculation and planning development.

[0019] The conveyor structure 3 is supported by an upper platform 4 . The upper platform is placed above at least one and preferably two pairs of wheel sets 10 which move laterally towards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com