Tension leg platform

A tension leg platform and tension leg technology, applied in the direction of floating buildings, etc., can solve the problems of difficulty in precise positioning in the plane, large vertical rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

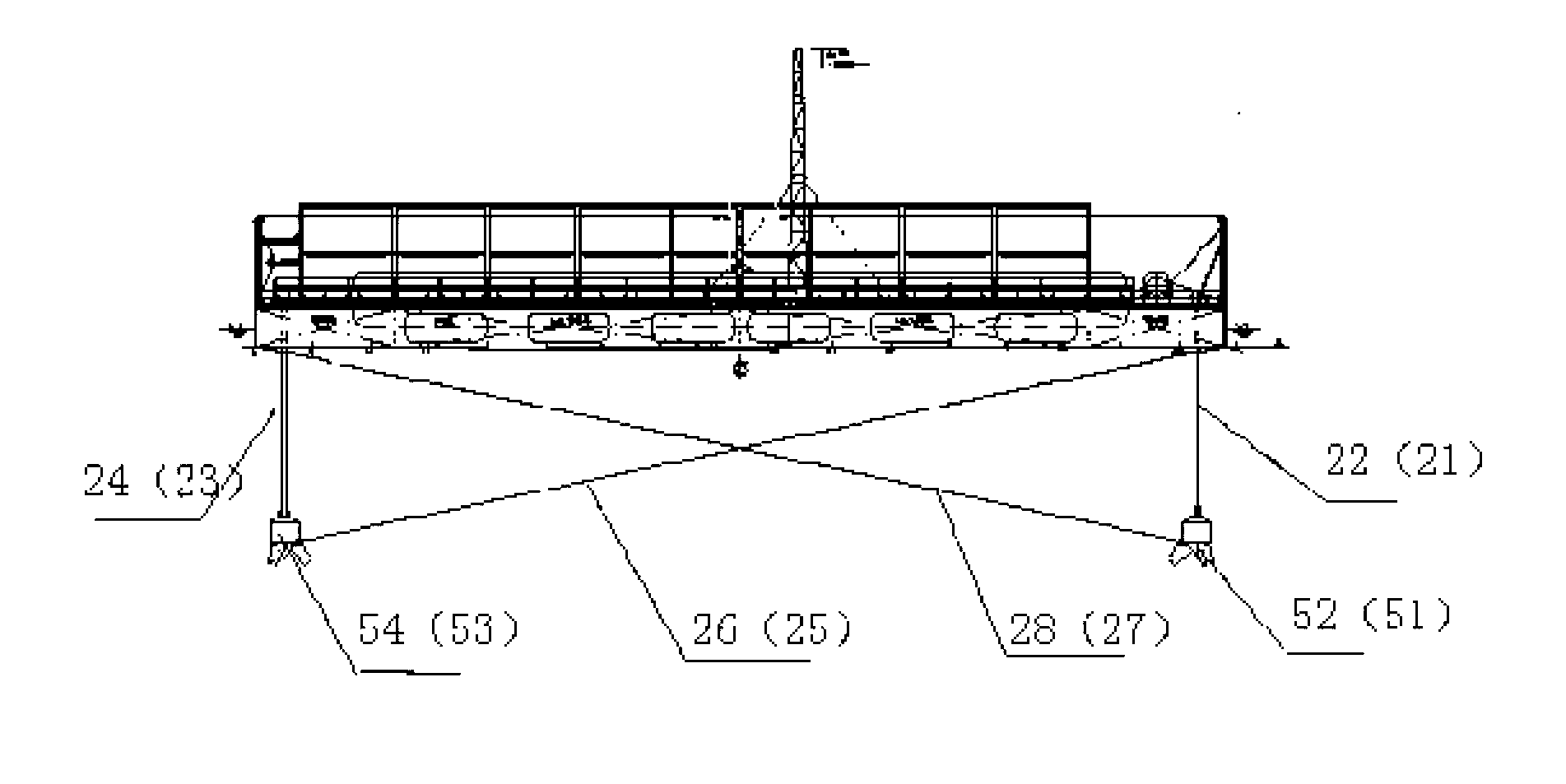

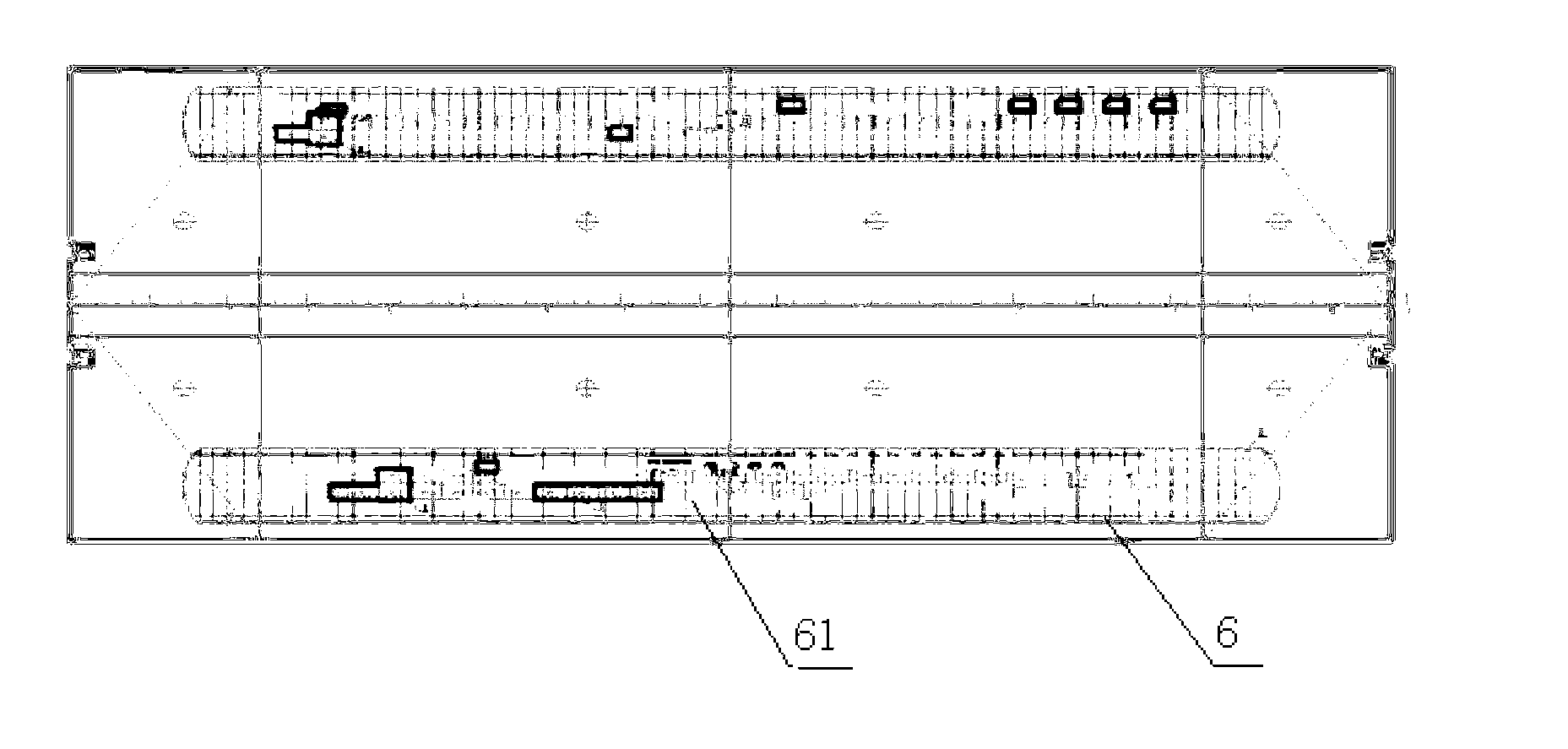

[0014] An underwater tension leg platform, its main dimensions are as follows: total length 50.40m, molded width 18.00m, molded depth 2.00m, beam arch: 0.36m, rib spacing: 0.60m, longitudinal spacing: 0.60m.

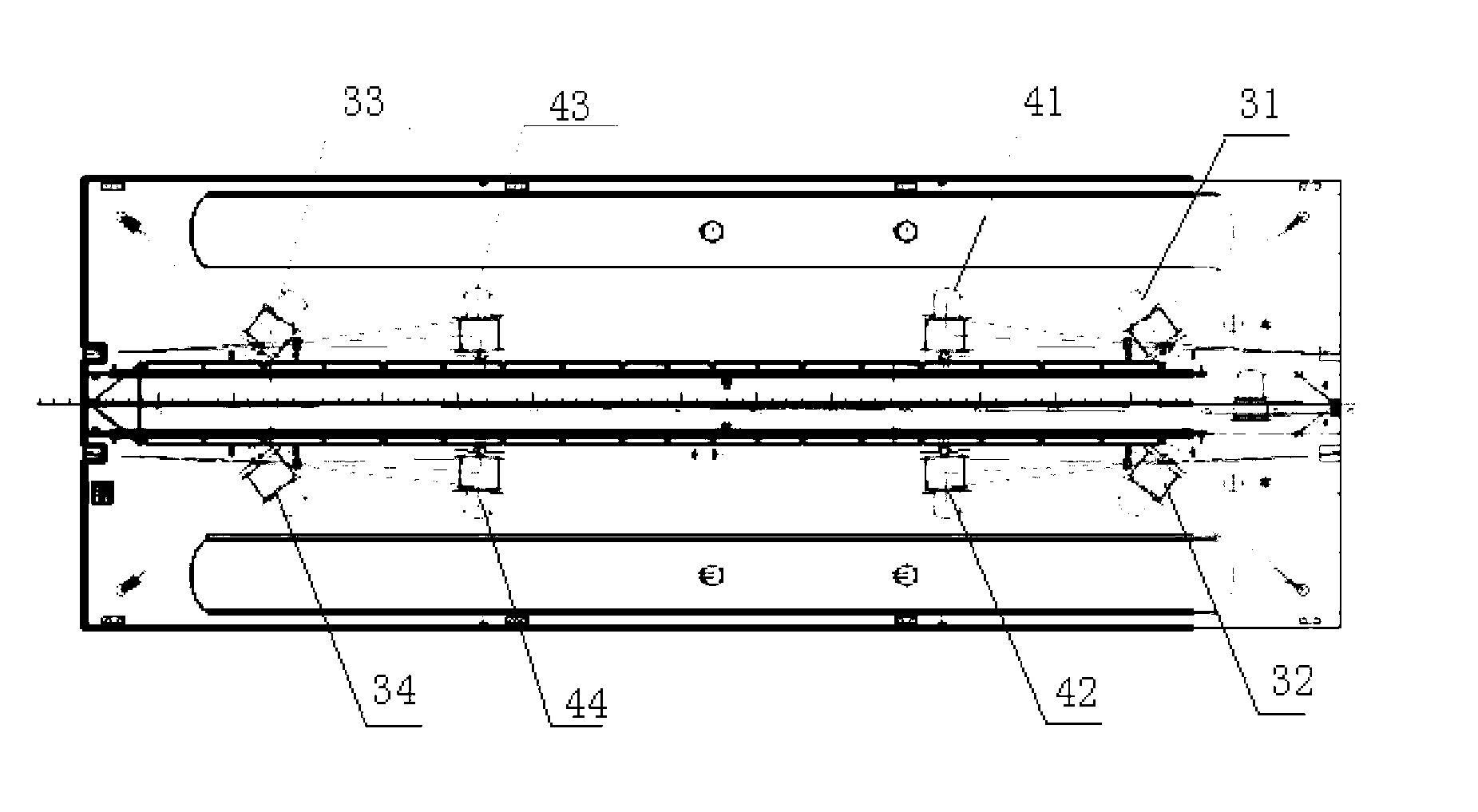

[0015] Such as figure 1 and figure 2 As shown, the tension leg platform includes a platform body 1, tension legs and four anchors, and the four anchors are respectively located at the front left, front right, rear left, and rear right bottom of the platform body. Steel cables and four cable-stayed steel cables; the front end of the upper part of the platform body is provided with a front left underwater tension winch 31, a front left underwater anchoring winch 41, a front right underwater tension winch 32, and a front right underwater anchoring winch 42. The upper rear end of the body 1 is provided with a rear left underwater tension winch 33, a rear left underwater anchoring winch 43, a rear right underwater tension winch 34, and a rear right underwater anchoring winc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com