Fibrous structure for a part made of composite material having one or more arch-shaped portions

A composite material, fiber structure technology, applied in the field of manufacturing composite material parts, can solve the problem of high total weight, can not provide mechanical strength and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

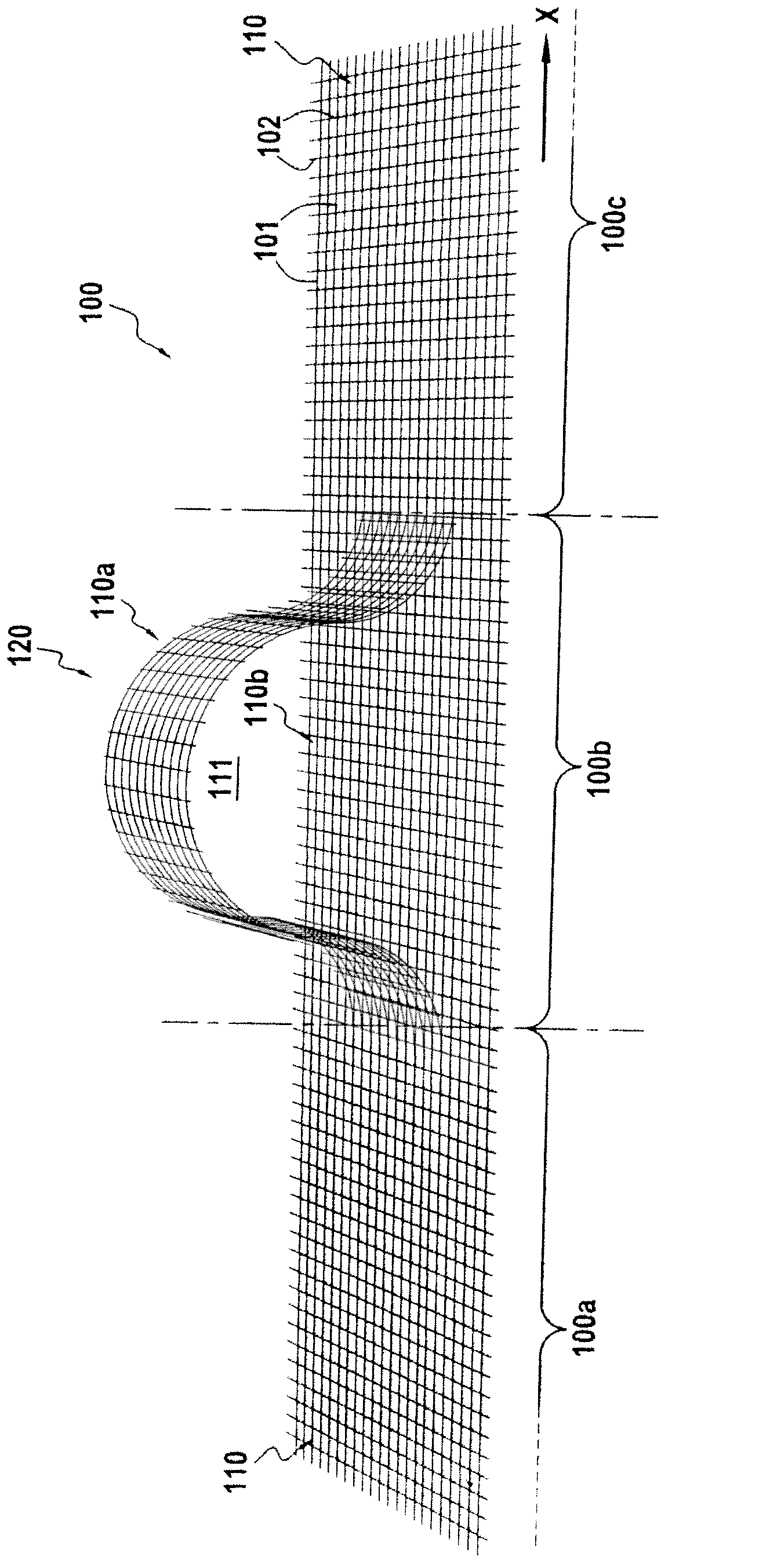

[0031] The invention is generally used for the manufacture of fiber structures suitable for constituting fiber reinforcements or preforms for the manufacture of composite parts comprising at least one arched element.

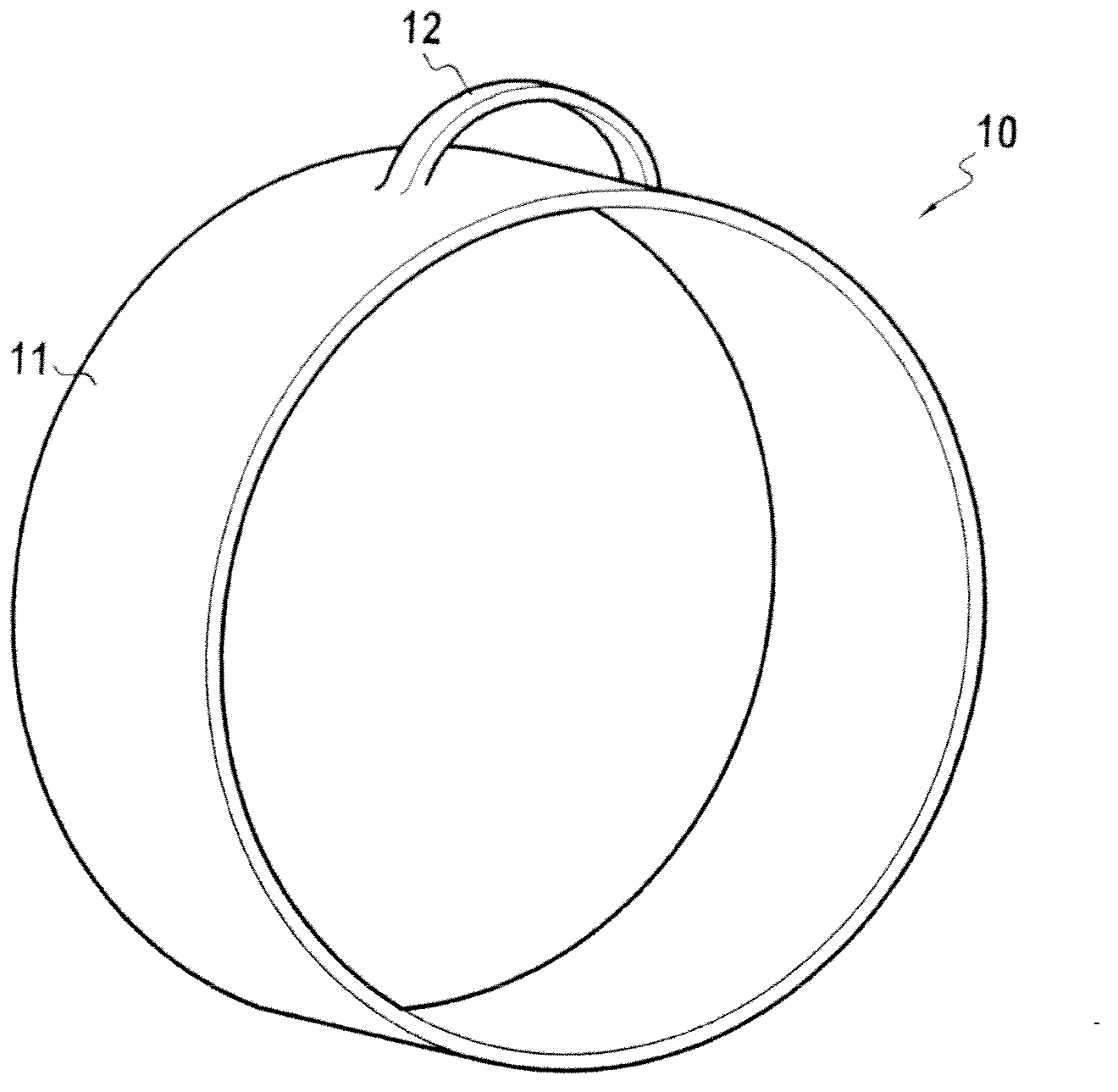

[0032] According to the invention, the part of the fiber structure forming the arched element is made integrally with the remainder of the fiber structure. More precisely, as described in more detail below, the portion forming the arched element is woven from warp yarns that are continuous with the remainder of the structure. In this way, the forces exerted on the arched element can be taken up by the fiber structure constituting the reinforcement of the composite material part as a whole. figure 1 Shown is a casing 10 of an aeroengine made of composite material forming a casing 11 having features for enabling the engine to be attached to wing supports (not shown on figure 1 Middle) on the suspension platform 12.

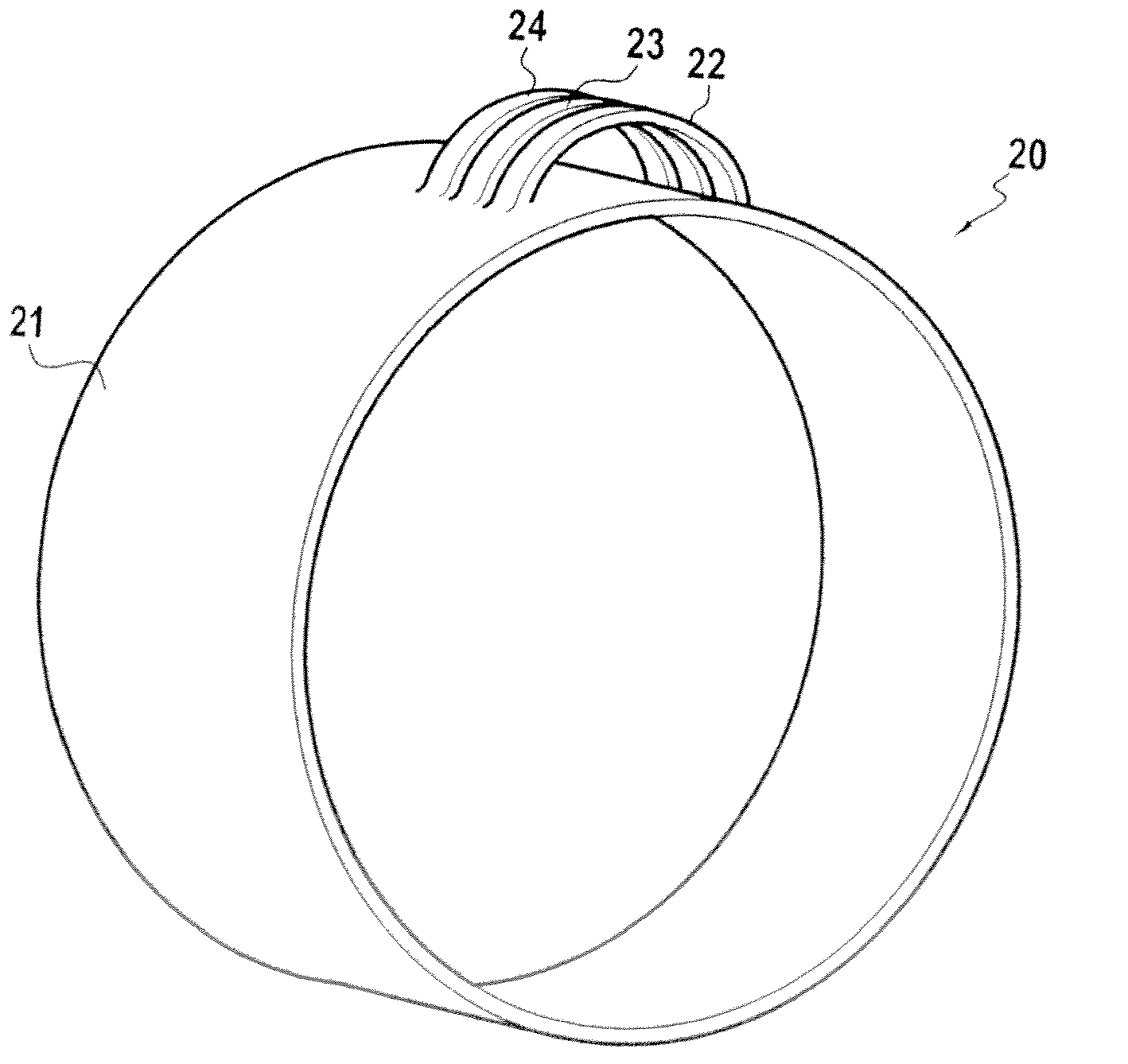

[0033] figure 2 is a very schematic view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com