Method for Estimating Residual Capacity of Power Lithium-ion Batteries in Different Temperature Environments

A technology for remaining battery power and lithium-ion batteries, which is applied in the field of power-type lithium-ion battery remaining power estimation, and can solve the problems of failing to truly reflect the SOC value and low accuracy of quadratic function fitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

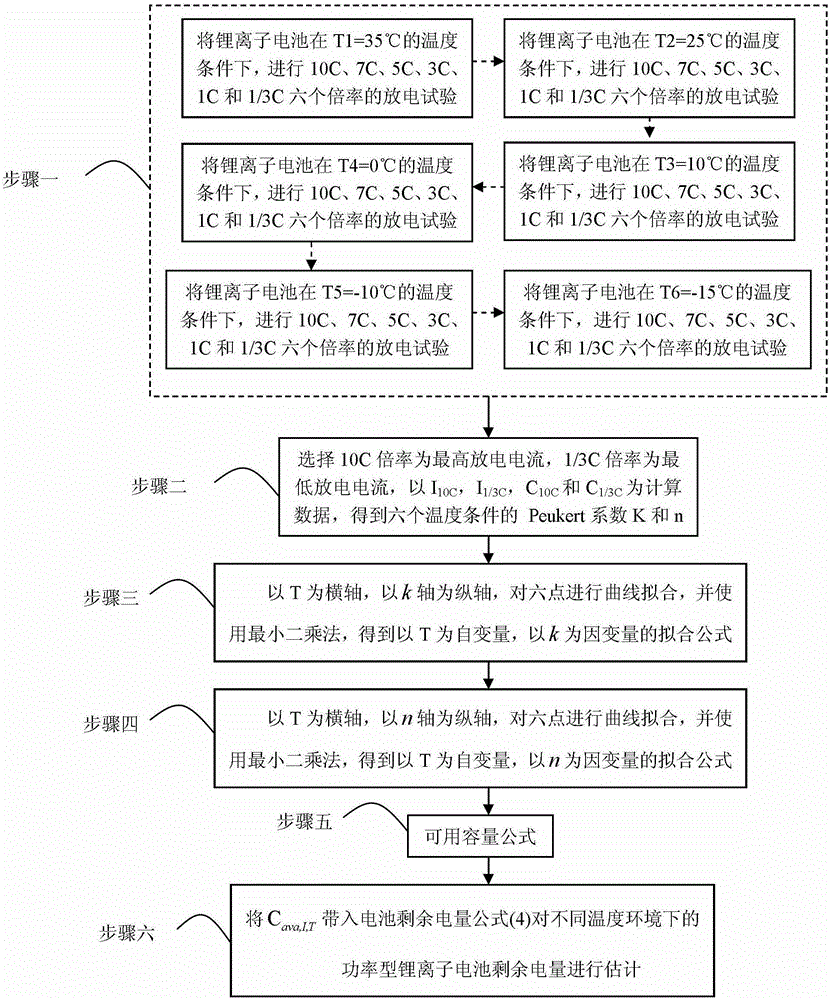

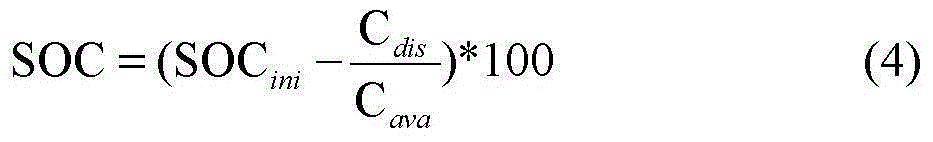

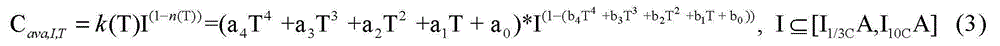

[0037] Specific implementation mode 1: The method for estimating the remaining power of a power type lithium-ion battery under different temperature environments in this implementation mode is implemented according to the following steps:

[0038] 1. Under the temperature condition of T1=35℃, the lithium-ion battery is subjected to six rate discharge tests of 10C, 7C, 5C, 3C, 1C and 1 / 3C, and the lithium-ion battery is tested at 10C, 7C, 5C, 3C, The discharge capacity of the six rates of 1C and 1 / 3C is denoted as C 10C1 , C 7C1 , C 5C1 , C 3C1 , C 1C1 , C 1 / 3C1 ;

[0039]Under the temperature condition of T2=25°C, the lithium-ion battery was subjected to six rate discharge tests of 10C, 7C, 5C, 3C, 1C and 1 / 3C, and the lithium-ion battery was tested at 10C, 7C, 5C, 3C, 1C and The discharge capacity of the six rates of 1 / 3C is denoted as C 10C2 , C 7C2 , C 5C2 , C 3C2 , C 1C2 , C 1 / 3C2 ;

[0040] Under the temperature condition of T3=10°C, the lithium-ion battery w...

specific Embodiment approach 2

[0066] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the lithium-ion battery is subjected to six steps of 10C, 7C, 5C, 3C, 1C and 1 / 3C under the temperature condition of T1=35°C. The specific rate discharge test is as follows:

[0067] Step 1: Charge the lithium-ion battery at a rate of 1 / 3C at room temperature;

[0068] Step 2: Place the lithium-ion battery in an incubator whose temperature is set to T1=35°C for 12 hours;

[0069] Step 3: Then discharge, discharge to the cut-off voltage, and record the discharge capacity of the lithium-ion battery at six rates of 10C, 7C, 5C, 3C, 1C and 1 / 3C, respectively denoted as C 10C1 , C 7C1 , C 5C1 , C 3C1 , C 1C1 , C 1 / 3C1 . Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0070] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, the lithium-ion battery is subjected to 10C, 7C, 5C, 3C, 1C and 1 / 3C under the temperature condition of T2=25°C The discharge test of six rates is as follows:

[0071] Step 1: Charge the lithium-ion battery at a rate of 1 / 3C at room temperature;

[0072] Step 2: Place the lithium-ion battery in an incubator whose temperature is set to T2 = 25°C for 12 hours;

[0073] Step 3: Then discharge, discharge to the cut-off voltage, and record the discharge capacity of the lithium-ion battery at six rates of 10C, 7C, 5C, 3C, 1C and 1 / 3C, respectively denoted as C 10C2 , C 7C 2,C 5C2 , C 3C2 , C 1C2 , C 1 / 3C2 . Other step parameters are the same as those in Embodiment 1 or 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap