Method for estimating energy type lithium ion battery remaining capacity in wide temperature environment

A technology for battery remaining power and lithium-ion batteries, which is applied in the field of energy-type lithium-ion battery remaining power estimation, and can solve the problem that the battery does not consider the impact of battery remaining power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

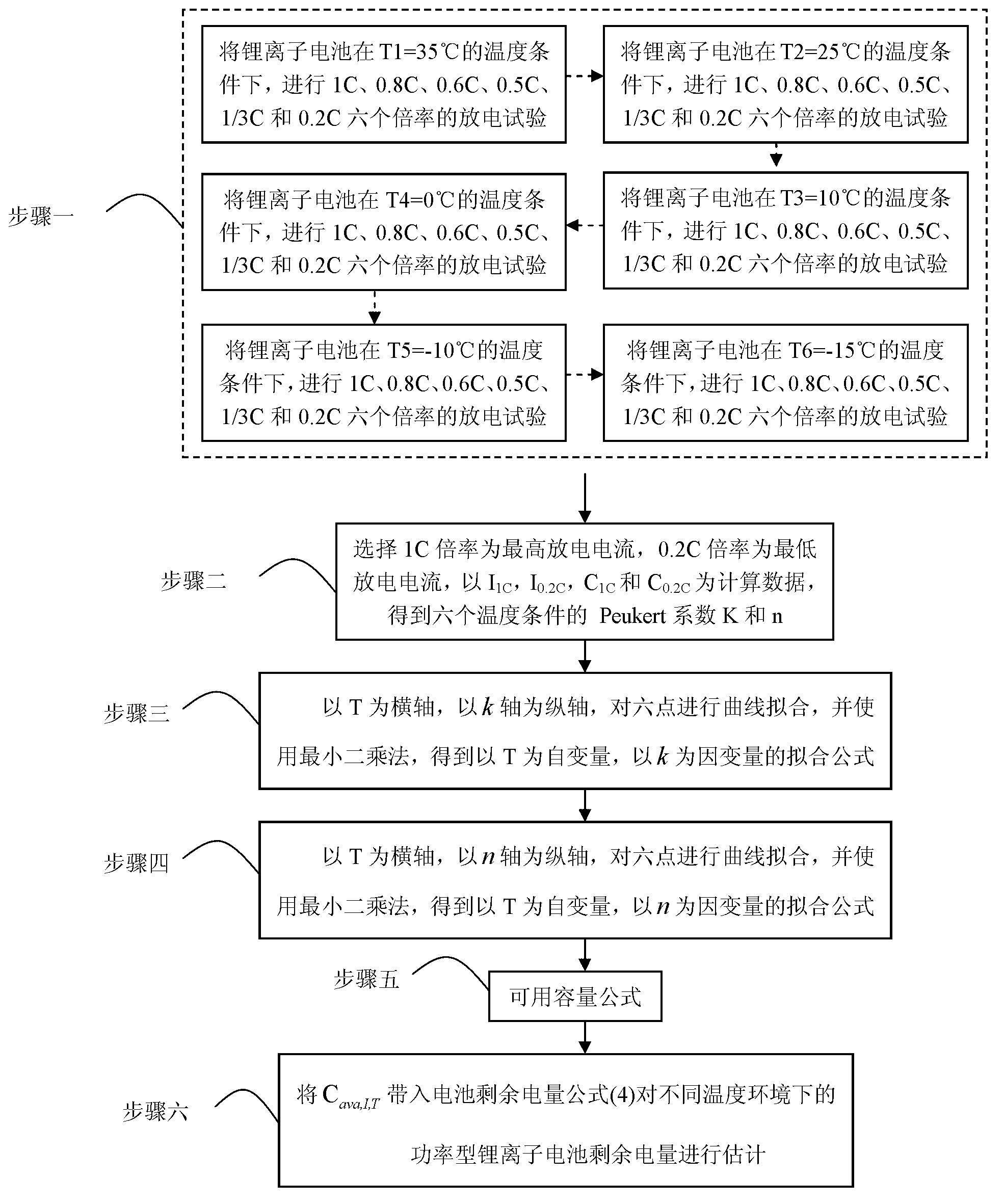

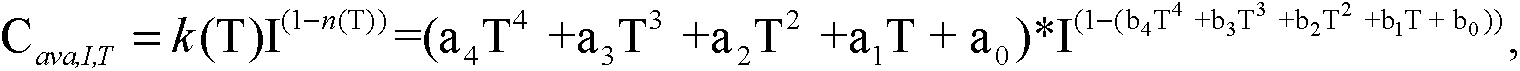

[0034] Specific Embodiment 1: The method for estimating the remaining power of an energy-type lithium-ion battery under a wide temperature environment in this embodiment is implemented in the following steps:

[0035] 1. Under the temperature condition of T1=35℃, the lithium-ion battery is subjected to six rate discharge tests of 1C, 0.8C, 0.6C, 0.5C, 1 / 3C and 0.2C, and the lithium-ion battery is obtained at 1C and 0.8C. , 0.6C, 0.5C, 1 / 3C and 0.2C, the discharge capacities of the six rates are denoted as C 1C1 , C 0.8C1 , C 0.6C1 , C 0.5C1 , C 1 / 3C1 , C 0.2C1 ;

[0036] Under the temperature condition of T2=25°C, the lithium-ion battery was subjected to six rate discharge tests of 1C, 0.8C, 0.6C, 0.5C, 1 / 3C and 0.2C, and the lithium-ion battery was tested at 1C, 0.8C, 0.6 The discharge capacity of six rates of C, 0.5C, 1 / 3C and 0.2C is denoted as C 1C2 , C 0.8C2 , C 0.6C2 , C 0.5C2 , C 1 / 3C2 , C0.2C2 ;

[0037] Under the temperature condition of T3=10°C, the lithi...

specific Embodiment approach 2

[0059] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the lithium-ion battery is subjected to 1C, 0.8C, 0.6C, 0.5C, 1 / 3C and The discharge test of the six rates of 0.2C is as follows:

[0060] Step 1: Under normal temperature conditions, charge the lithium-ion battery at a rate of 1 / 3C until it is fully charged;

[0061] Step 2: Place the lithium-ion battery in an incubator whose temperature is set to T1=35°C for 12 hours;

[0062] Step 3: Then discharge, discharge to the cut-off voltage, and record the discharge capacity of the lithium-ion battery at six rates of 1C, 0.8C, 0.6C, 0.5C, 1 / 3C and 0.2C, respectively denoted as C 1C1 , C 0.8C1 , C 0.6C1 , C 0.5C1 , C 1 / 3C1 , C 0.2C1 .

[0063] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0064] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, the lithium-ion battery is subjected to 1C, 0.8C, 0.6C, 0.5C, 1 / The discharge test of six rates of 3C and 0.2C is as follows:

[0065] Step 1: Under normal temperature conditions, charge the lithium-ion battery at a rate of 1 / 3C until it is fully charged;

[0066] Step 2: Place the lithium-ion battery in an incubator whose temperature is set to T2 = 25°C for 12 hours;

[0067] Step 3: Then discharge, discharge to the cut-off voltage, and record the discharge capacity of the lithium-ion battery at six rates of 1C, 0.8C, 0.6C, 0.5C, 1 / 3C and 0.2C, respectively denoted as C 1C2 , C 0.8C2 , C 0.6C2 , C 0.5C2 , C 1 / 3C2 , C 0.2C2 .

[0068] Other step parameters are the same as those in Embodiment 1 or 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap