A working method of a workbench with automatic level and height adjustment

A working method and automatic adjustment technology, applied in the direction of workbench, manufacturing tool, lifting device, etc., can solve the problem that the work surface cannot be leveled, and achieve the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

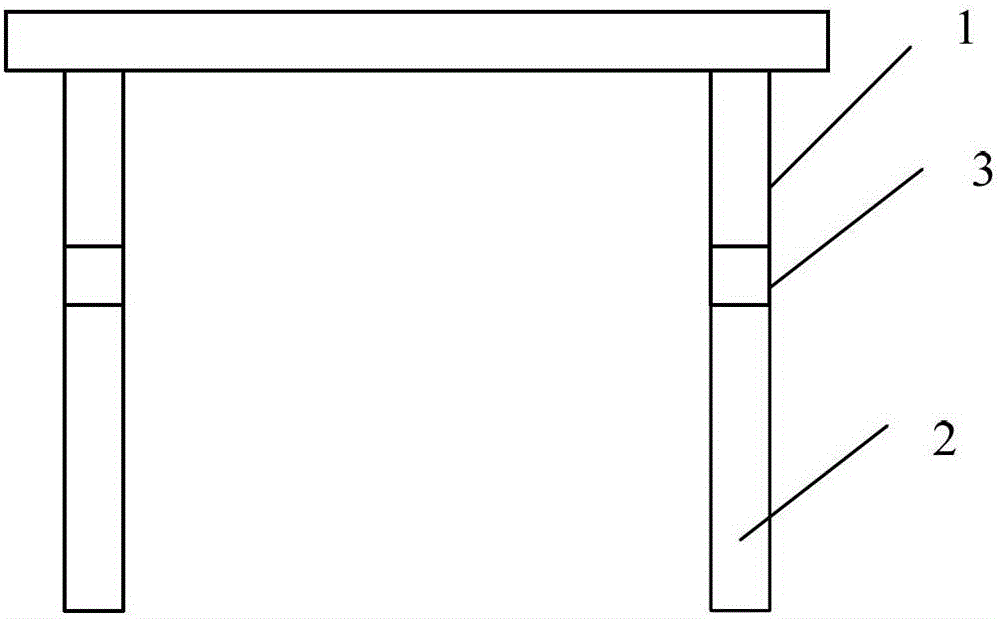

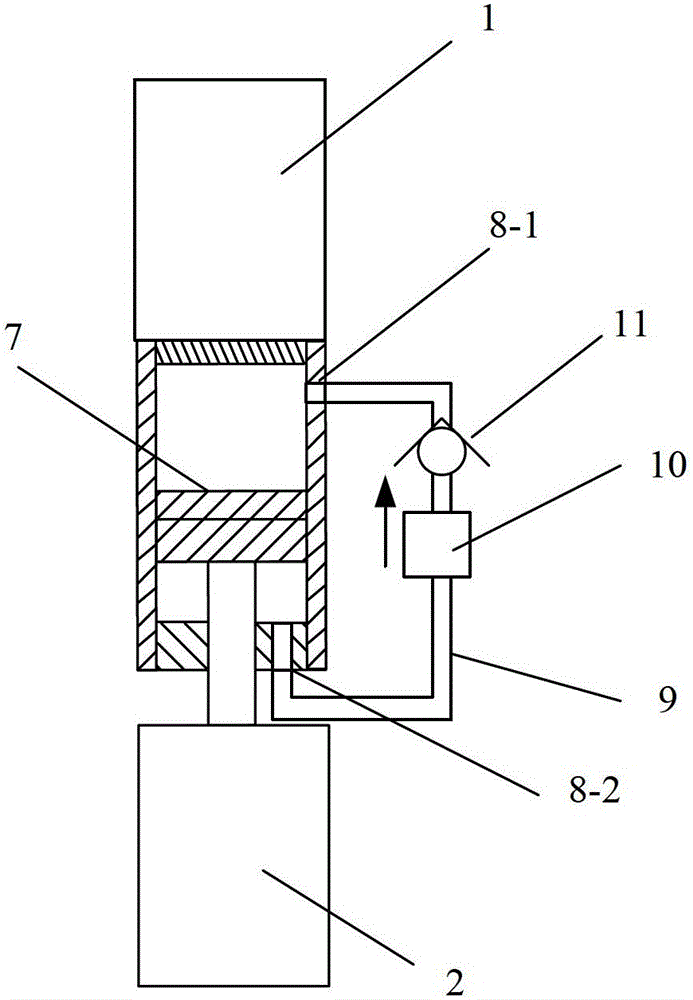

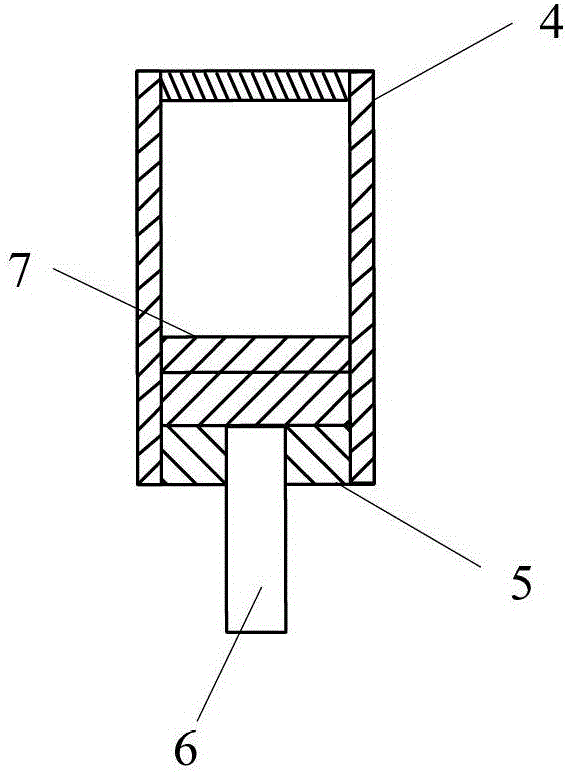

[0019] See figure 1 , figure 2 , image 3 , Image 6 , a working method for a workbench that automatically adjusts the level and height, the workbench includes: at least three height-adjustable outrigger assemblies for supporting the worktable surface, and the outrigger assemblies include: an upper outrigger 1 and the lower leg 2, and the lifting mechanism 3 located between the upper and lower legs 2; the lifting mechanism 3 includes: a cylinder 4 that is cylindrical and used to fill the buffer medium, and the cylinder 4 The opening end seal of the cylinder head 5 is provided with a cylinder cover 5, and a piston rod 6 is fitted in the center through hole 7-3 of the cylinder cover 5 for sealing and movable movement. The upper end of the piston rod 6 is provided with a piston body assembly 7, and the piston body assembly 7 It is in active sealing cooperation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com