Worktable automatically adjustable in level and height

一种自动调节、工作台的技术,应用在工作台、制造工具、提升装置等方向,能够解决工作台面无法水平等问题,达到提高速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

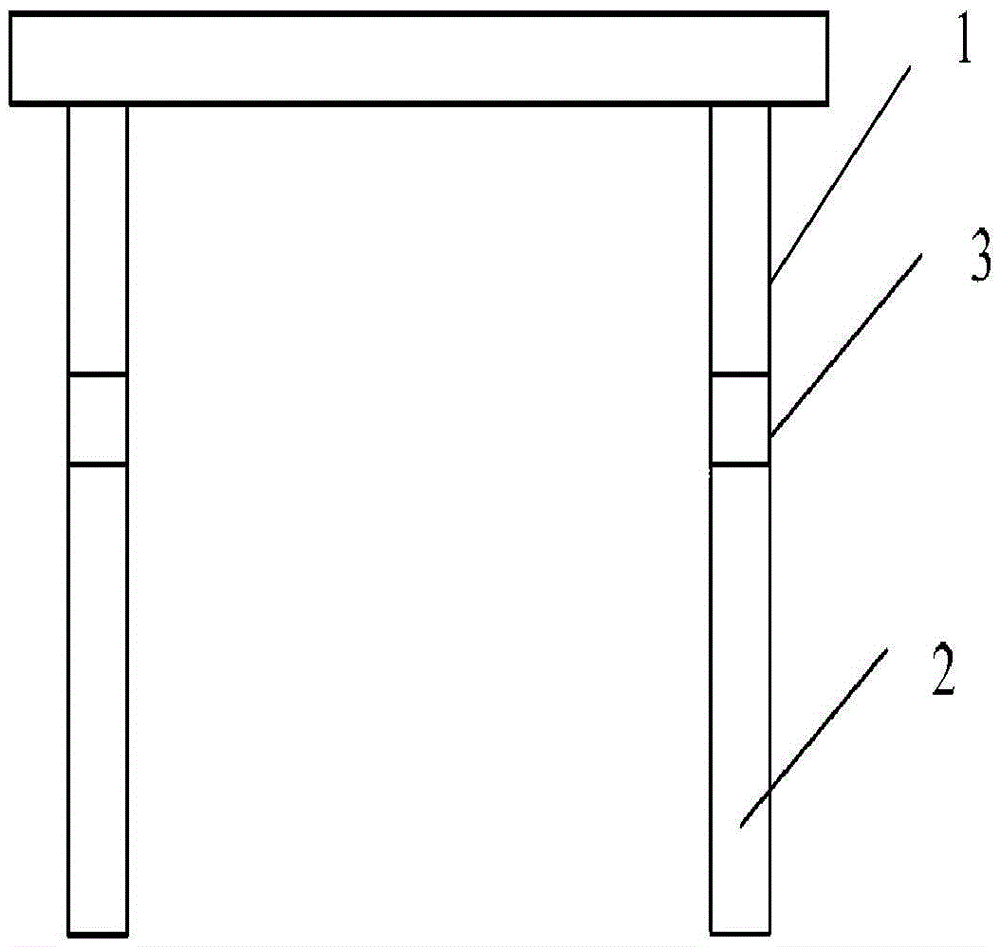

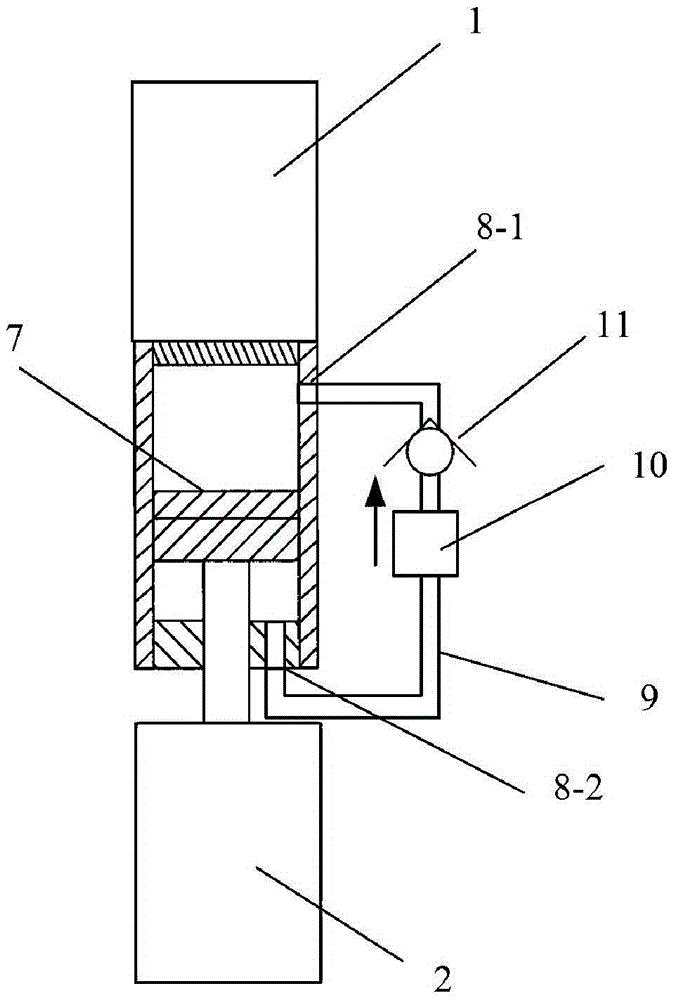

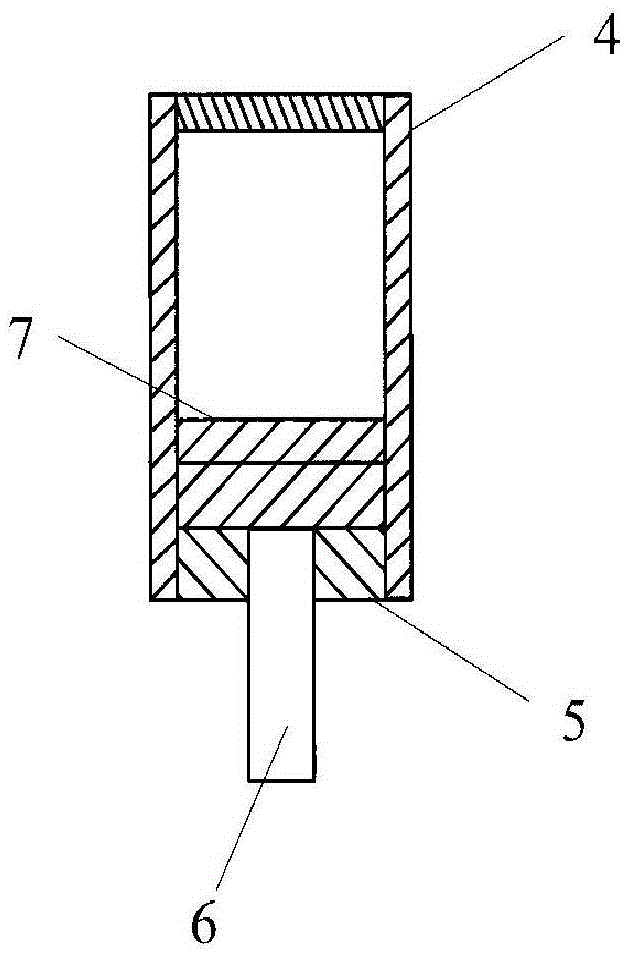

[0019] See figure 1 , figure 2 , image 3 , Image 6 , a working method for a workbench that automatically adjusts the level and height, the workbench includes: at least three height-adjustable outrigger assemblies for supporting the worktable surface, and the outrigger assemblies include: an upper outrigger 1 and the lower leg 2, and the lifting mechanism 3 located between the upper and lower legs 2; the lifting mechanism 3 includes: a cylinder 4 that is cylindrical and used to fill the buffer medium, and the cylinder 4 The opening end seal of the cylinder head 5 is provided with a cylinder cover 5, and a piston rod 6 is fitted in the center through hole 7-3 of the cylinder cover 5 for sealing and movable movement. The upper end of the piston rod 6 is provided with a piston body assembly 7, and the piston body assembly 7 It is in active sealing cooperation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com