Test tube cover collection mechanism

A collection mechanism and test tube cover technology, applied in the field of medical devices, can solve the problems of low efficiency, complicated structure and operation, and achieve the effect of reliable recovery operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

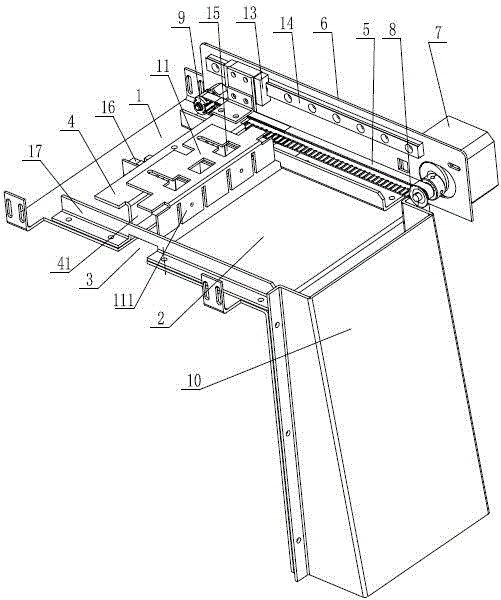

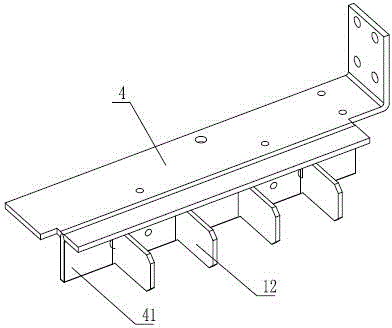

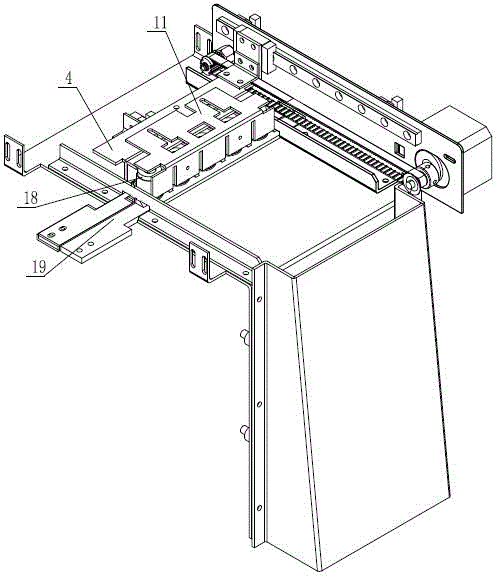

[0019] See figure 1 , figure 2 , the present invention comprises connecting plate one 1 and connecting plate two 2, leave transverse gap 3 between connecting plate one 1 and connecting plate two 2, the top of transverse gap 3 is provided with push plate 4, and push plate 4 is fixed with conveyor belt 5 Then, the mounting plate 6 is longitudinally fixed on the connecting plate one 1 and the connecting plate two 2, the motor 7 is fixed on the mounting plate 6, the output shaft of the motor 7 is connected with the main pulley 8, and the main pulley 8 is connected with the mounting plate 6. The other end is wound with a transmission belt 5 from the pulley 9; the side of the connecting plate 2 is provided with a recycling box 10; The plate 11 has a vertical arm 2 111. The push plate 4 and the cover plate 11 form a covering space with an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com