Sealing device

A technology of sealing device and sealing ring, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of liquid penetration, gas leakage in pneumatic diaphragm pumps, etc., and achieve the effect of improving sealing and confidentiality performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

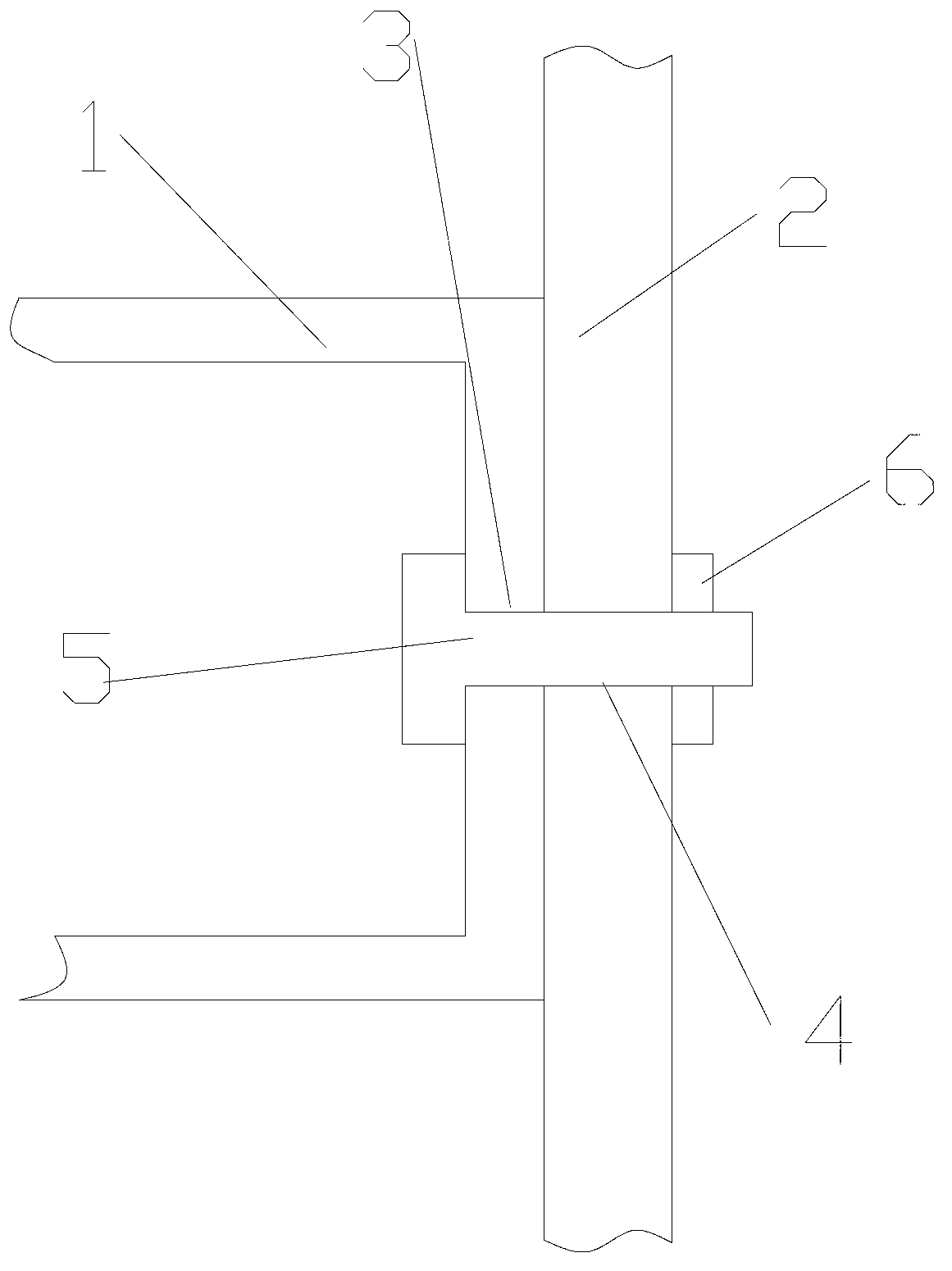

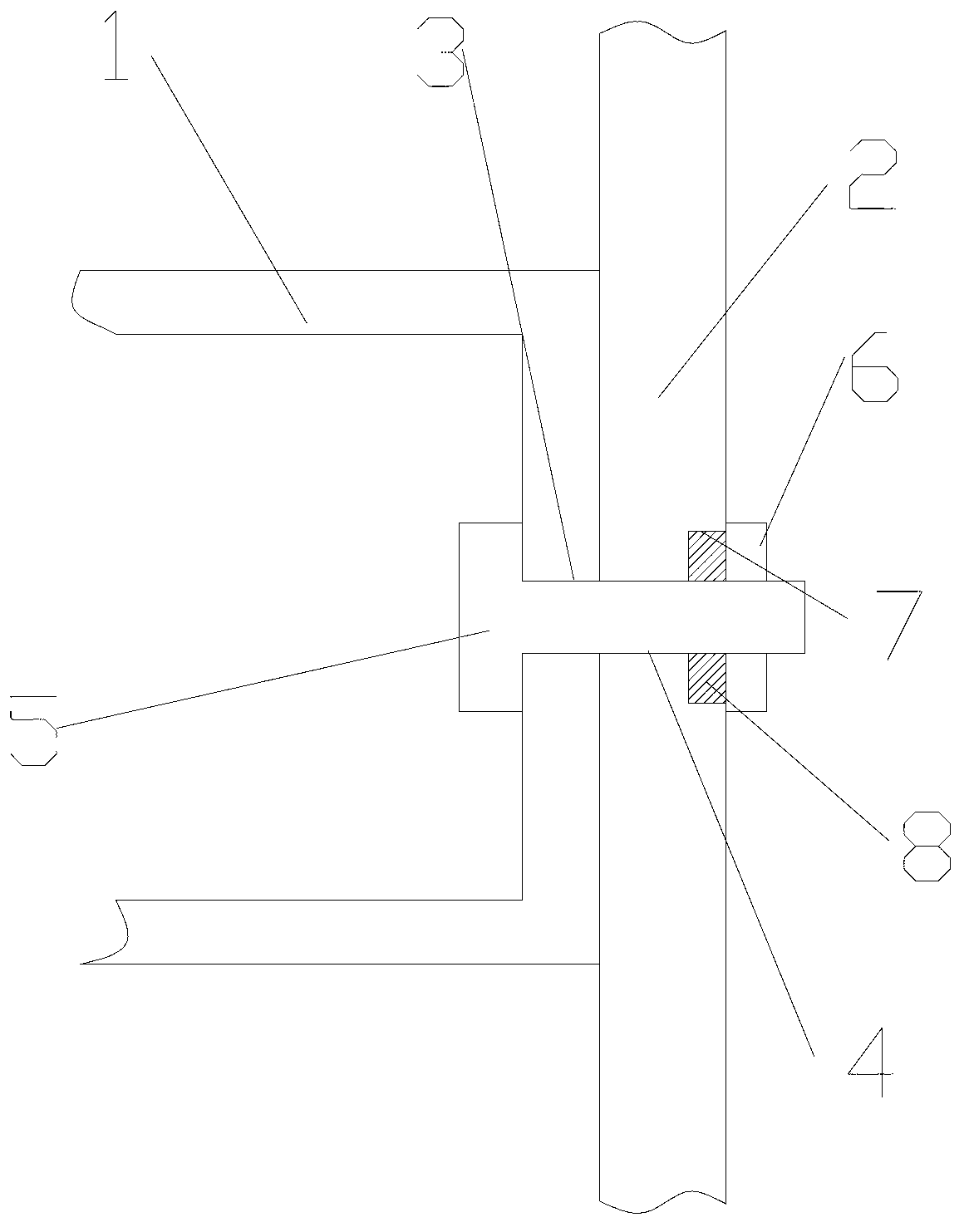

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 2 It is a sealing device according to the present invention, which includes a central body 1 and an air chamber end cover 2, the central body 1 and the air chamber end cover 2 respectively have a first through hole 3 and a second through hole 4, and bolts 5 It is connected and fixed with the nut 6; the air chamber end cover 2 is provided with a groove 7 at the position of the second through hole 4, and a sealing ring 8 is arranged in the groove 7.

[0014] Wherein the groove 7 is arranged on the side of the air chamber end cover 2 away from the central body 1 . .

[0015] During the use of the sealing device of the present invention, the seal ring 8 provided in the groove 7 is completely sealed between the bolt 5 and the end cover 2 of the air chamber, which effectively improves the sealing between the central body 1 and the end cover of the air chamber. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com