Fuel filter system with alarm function and alarm method thereof

A technology of fuel filtration and function, applied in the direction of charging system, liquid fuel feeder, engine components, etc., to ensure normal operation, avoid delaying maintenance time, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

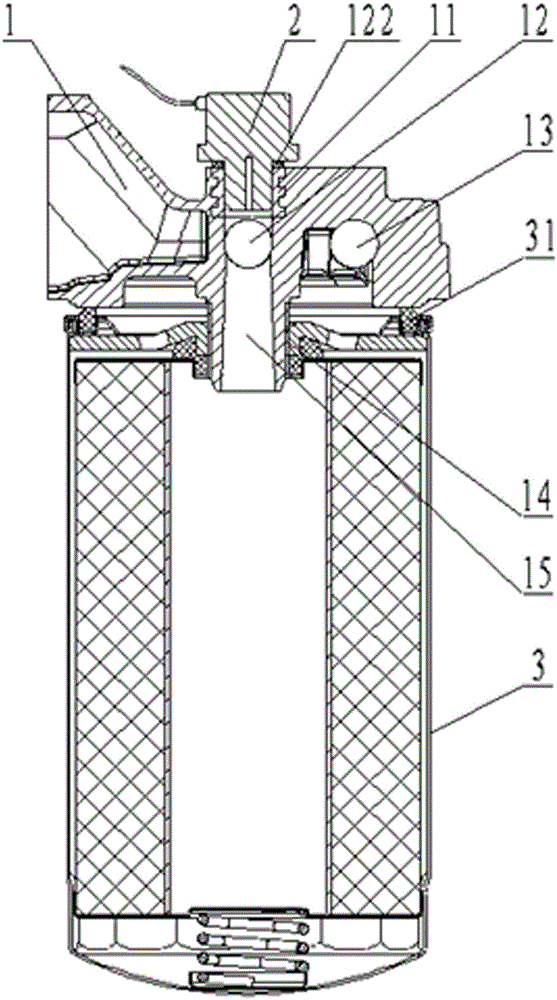

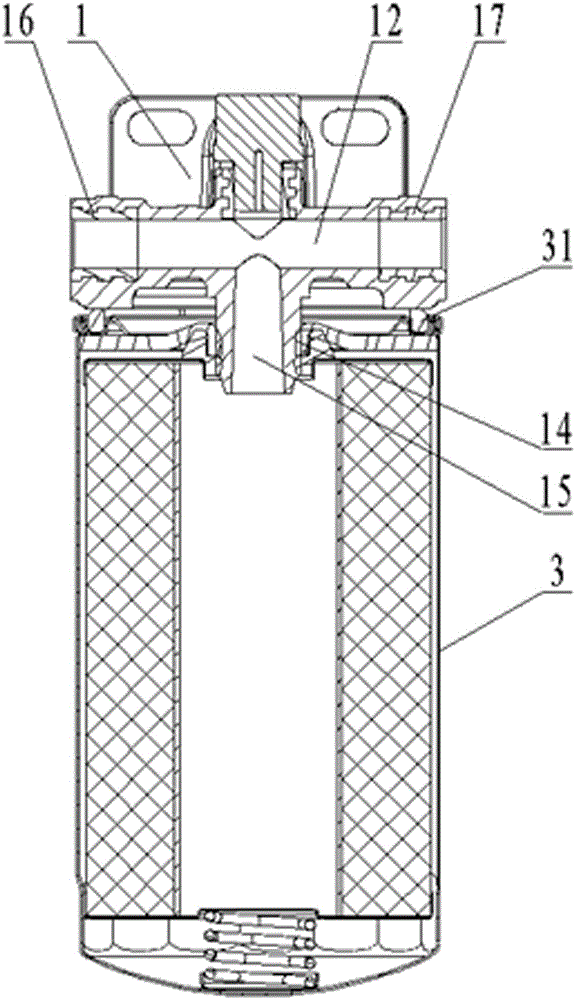

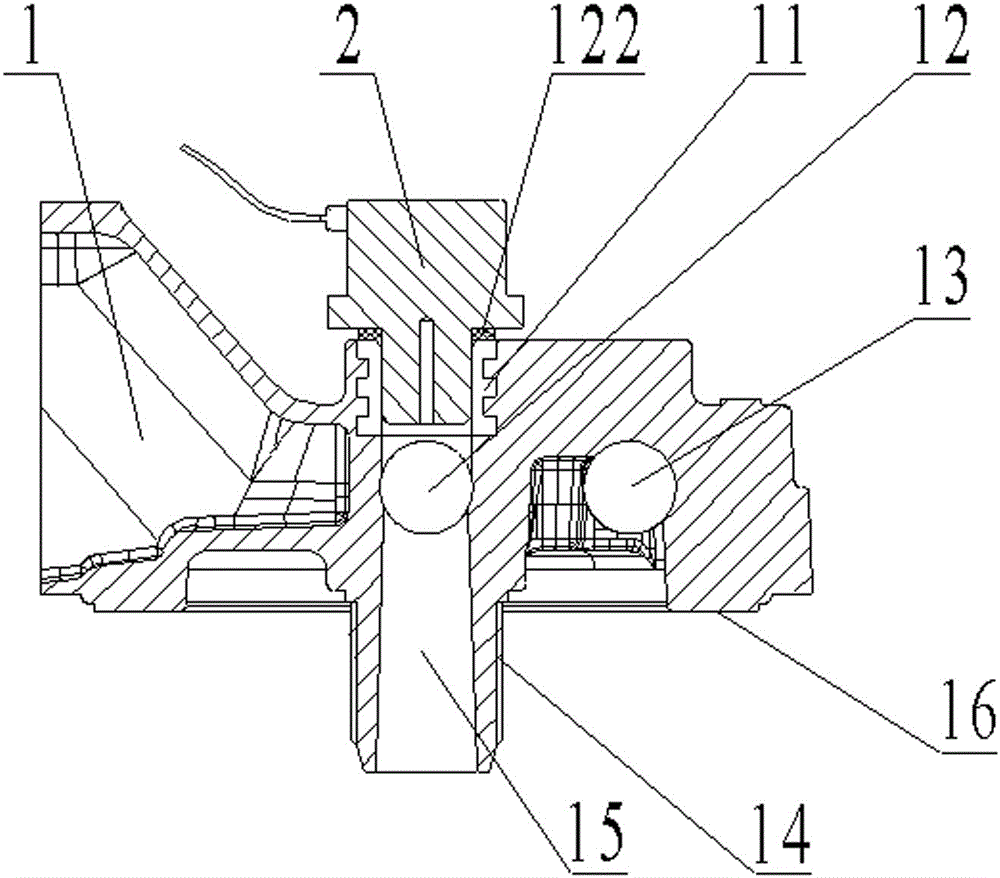

[0033] refer to Figure 1-6 As shown, the general idea of the present invention is to provide a fuel filter system with an alarm function, which includes a filter seat 1 and a filter tank 3 installed on the filter seat 1, wherein: in the filter seat 1 is also equipped with a negative pressure alarm device 2 for monitoring the oil outlet pressure of the fuel filter system. The installation position of the negative pressure alarm device 2 can be arranged on the filtered oil outlet side of the filter seat 1, or at the upper end of the filter tank 3 installation pipe thread inner cavity, or at any position of the oil outlet channel of the filter seat. Location. In this way, due to the use of the negative pressure alarm device 2, the pressure state of the filter can be monitored in real time, and the monitored state can be fed back to the user, thereby correctly guiding the user to maintain the filter element of the filter and avoiding unnecessary filter elements. Maintenance o...

Embodiment 2

[0042] Such as Figure 10 As shown, the present embodiment is the same as the first embodiment except that the indicator light module, that is, the first color lamp 22, the second color lamp 23 and the third color lamp 24 are non-integrated packages in the installation form, It is independently installed on the control panel of the cab or at an easy-to-observe position on the engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com