Air returning device on material discharging side of drying channel

A technology of discharge side and drying tunnel, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of heat loss in drying tunnel, waste of energy, temperature deviation of drying tunnel, etc., and achieve the effect of saving heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

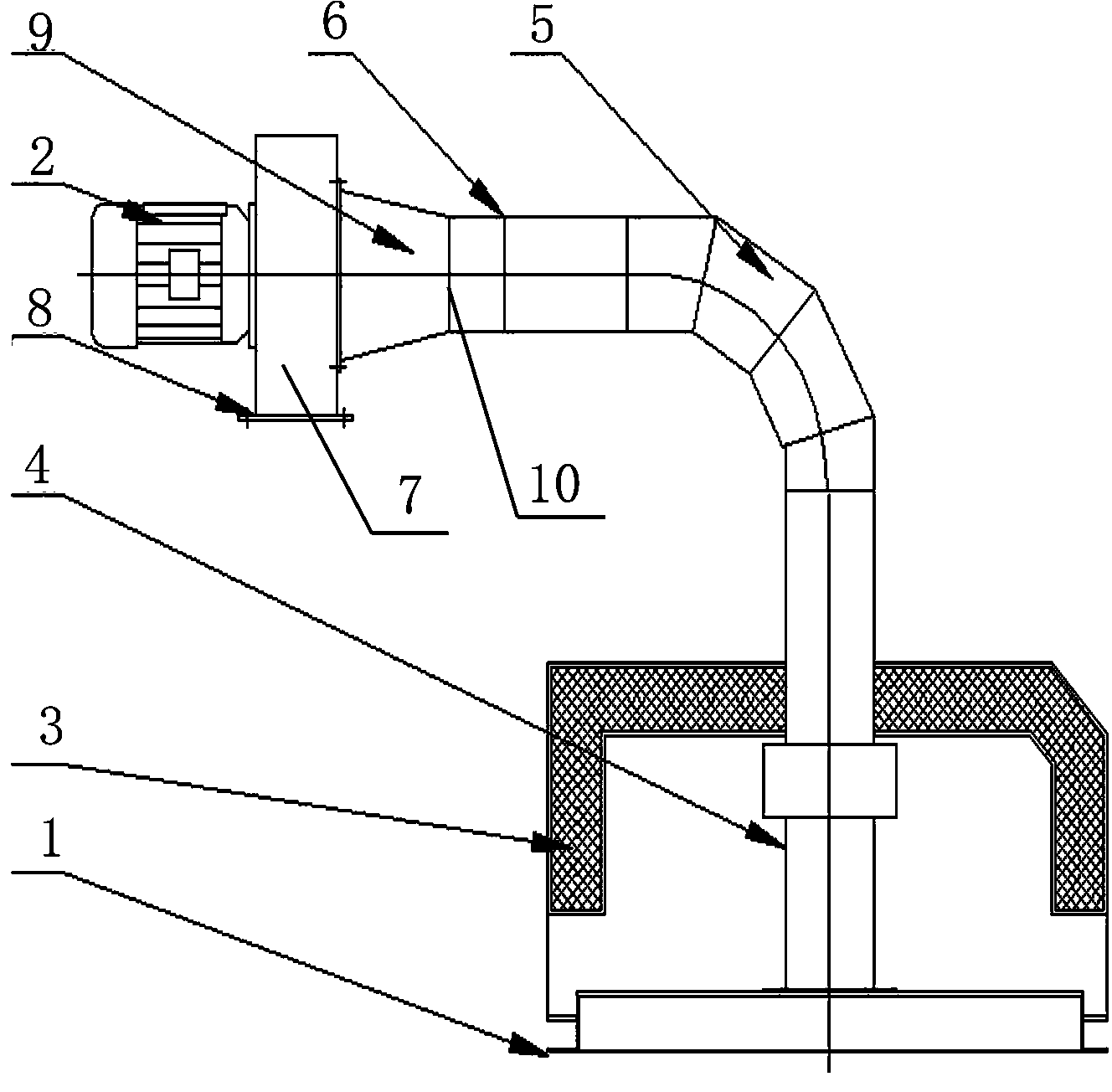

[0008] exist figure 1 Among them, the present invention provides a return air device on the discharge side of the drying tunnel, which is provided with a return air box 1 and a return air fan 2, and a return air cover 3 is provided on the top of the return air box 1, and a return air return box is provided in the return air box 1 The air duct 4 and the return air duct 4 pass upward through the return air cover 3 and extend out of the return air box 1, and then are connected with an elbow 5 and a straight pipe 6 in turn. One end of the straight pipe 6 is connected to the elbow 5, and the other end of the straight pipe 6 It communicates with the tuyere 7 of the return air fan 2, and a damper adjustment plate 8 is provided at the lower part of the tuyere 7, and a tapered pipe 9 is provided between the other end of the straight pipe 6 and the tuyere 7 of the return air fan 2 for transition connection , the other end of the straight pipe 6 is connected with the tapered pipe 9 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com