Control method for temperature of thermal treatment heating furnace

A control method and heating furnace technology, applied in the direction of heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problems of reducing the waste rate of heat treatment, etc., to achieve the effect of reducing the waste rate and solving temperature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

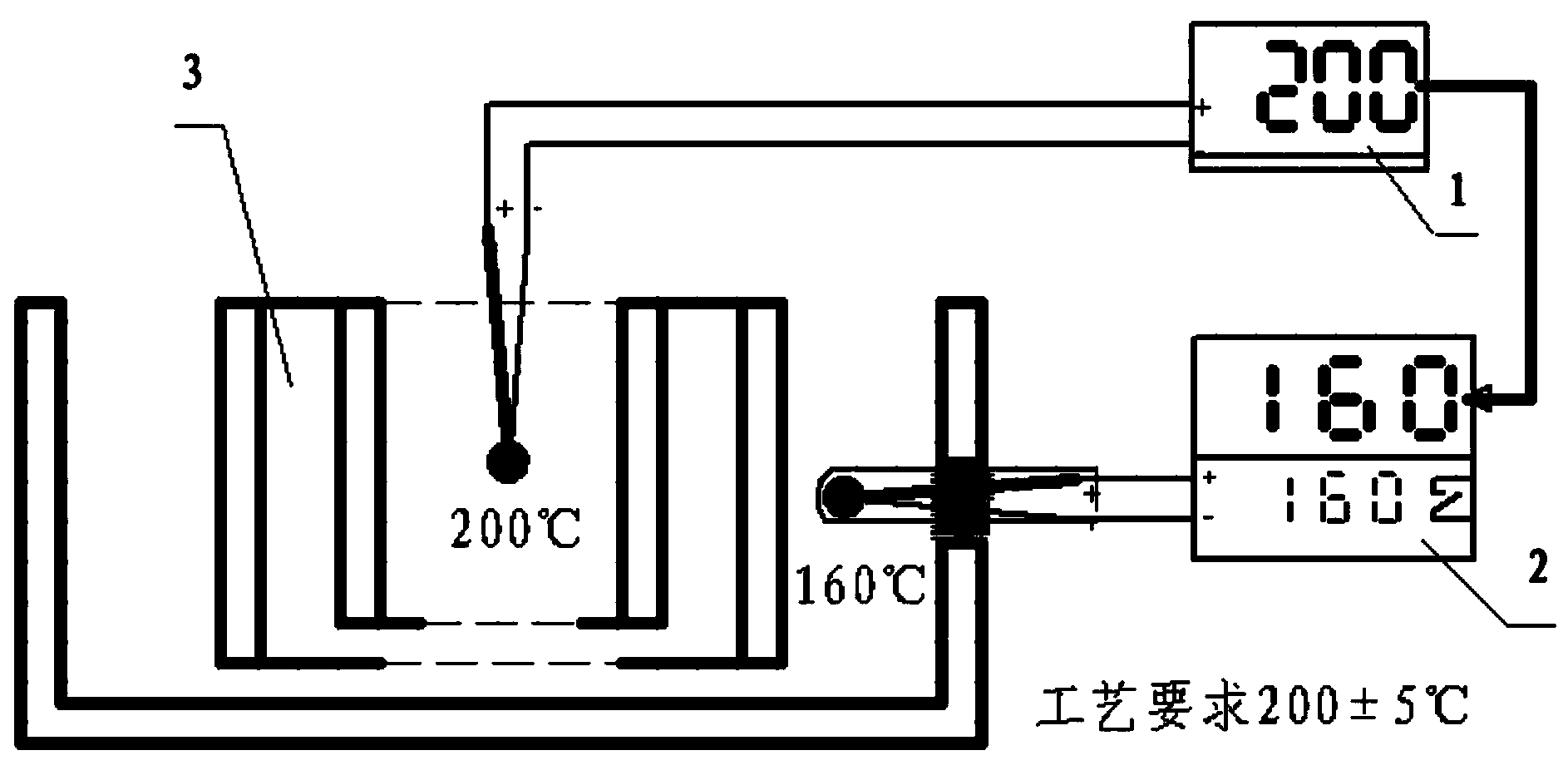

[0012] A method for controlling the temperature of a heat treatment furnace of the present invention is that when the ambient temperature changes, before the workpiece to be processed is heat treated, the measurement and control instrument 2 in the original measurement and control system is first corrected, and then the original measurement and control system is used to heat the heat treatment The furnace performs temperature control, and the environmental temperature change value that needs to be corrected is determined according to the process specified temperature range of the workpiece to be processed, that is, the larger the process specified temperature range, the greater the environmental temperature change value that needs to be corrected, otherwise the smaller.

[0013] The specific two steps for correcting the measurement and control instrument in the original measurement and control system are as follows:

[0014] 1) A monitoring system is added on the basis of the origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com