A self-locking weighing bucket mechanism

A weighing hopper and self-locking technology, which is applied in the field of self-locking weighing hopper mechanism, can solve the problem that the opening and closing speed of the weighing hopper door is not easy to control the stability of the overall weighing mechanism, the load capacity of the weighing sensor is large, and the weighing Low precision and other problems, to achieve reasonable structural design, ensure stability, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

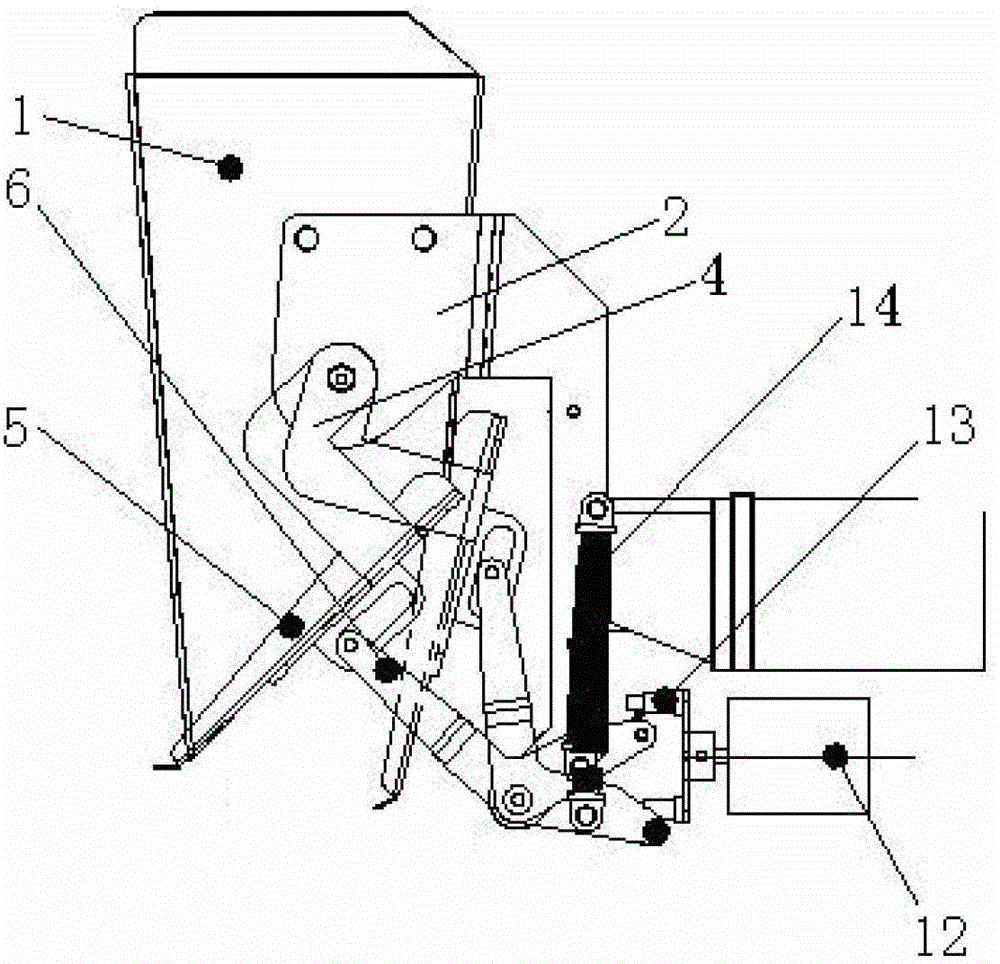

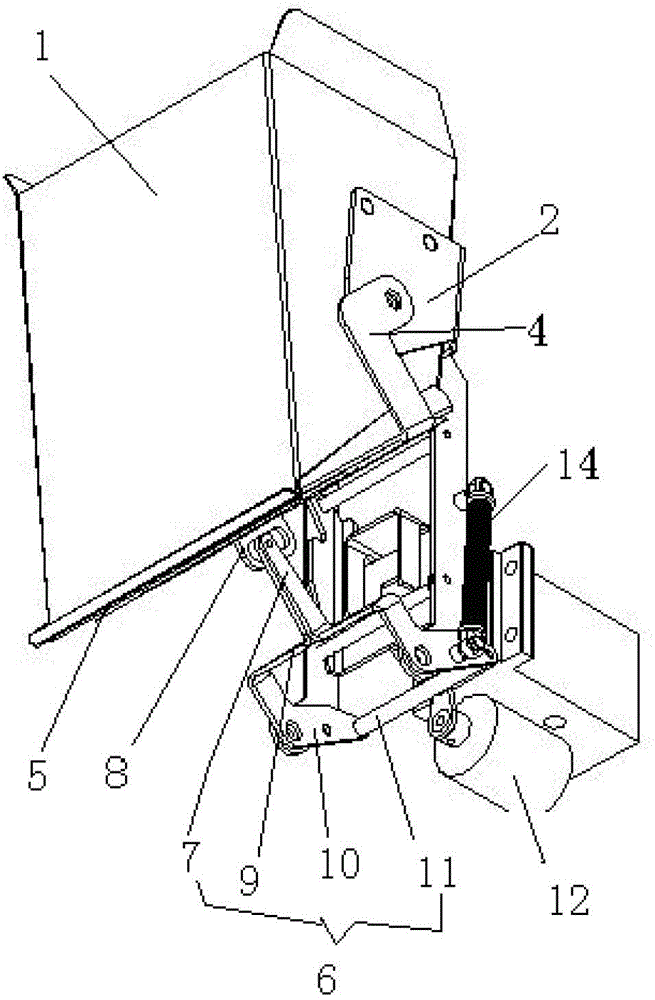

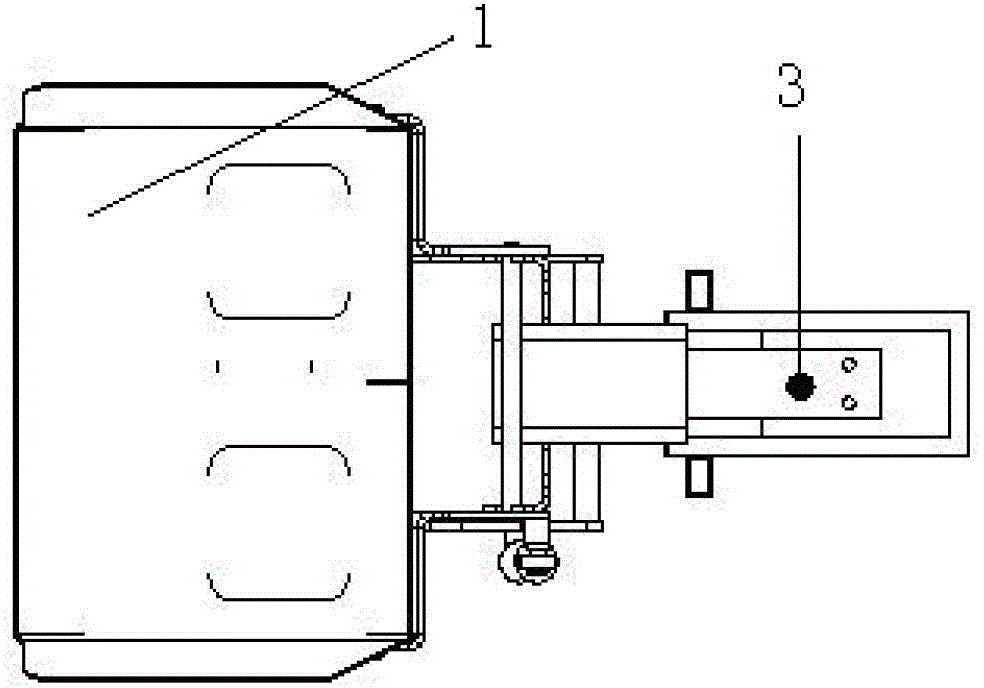

[0012] Referring to the accompanying drawings, a self-locking weighing bucket mechanism includes a bucket body 1, a weighing bucket bracket 2 is provided on both sides of the bucket body 1, and a load-bearing sensor 3 is installed on the support outside the weighing bucket bracket 2 , the weighing bucket support 2 is respectively rotated and installed with an L-shaped rotating force arm 4, the lower end of the L-shaped rotating force arm 4 is fixedly connected with the bucket door 5 below, and the bucket door 5 cooperates with the discharge port of the bucket body 1, and the bottom of the bucket door 5 The middle part of the end face is connected with the upper end of the rotating arm 6 below, and the rotating arm 6 includes a pull rod 7, one end of the pull rod 7 is connected with the connection fixing ear 8 provided in the middle part of the lower end face of the bucket door, and the other end is provided with a cross bar 9, The two ends of cross bar 9 are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com