Containing la, ce, pr and nd scale-like multi-element aluminum-zinc-silicon alloy powder and its preparation method

A scale-shaped, zinc-aluminum alloy technology, applied in the field of scale-shaped multi-element aluminum-zinc-silicon alloy powder and its preparation, can solve the problem of restricting the industrialization process of chromium-free zinc-aluminum coating technology, affecting the use range and quality of metal powder, metal The powder is easy to oxidize and other problems, and achieves the effect of high flake degree, cost reduction and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

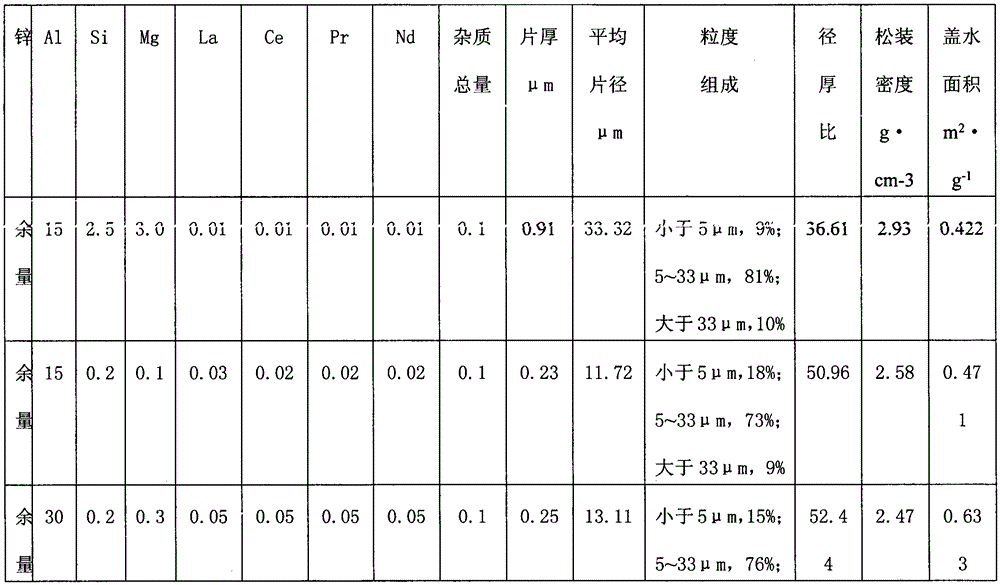

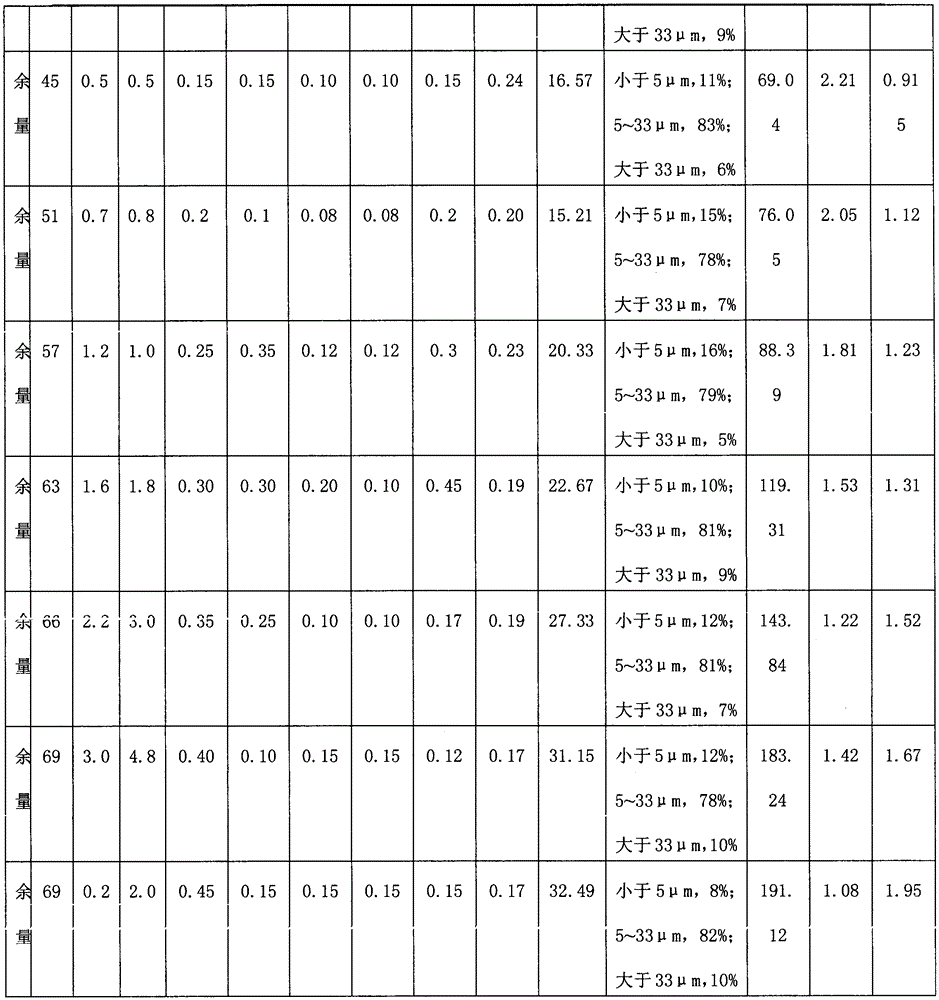

Embodiment 1

[0043] Take 10Kg of 300-mesh aluminum-zinc-silicon alloy powder raw material, 0.4Kg of zinc stearate, and 200Kg of steel balls into the ball mill. After vacuuming, nitrogen is introduced, and cooling water is connected to ensure that the temperature during the ball milling process is between 30-40°C. . After ball milling at a speed of 50r / min for 10 hours, the material is discharged, and the ball milled powder is put into a polishing machine for polishing. The polished powder is classified to obtain flake Al-Zn-Si alloy powder.

Embodiment 2

[0045] Get 10Kg of 200-mesh aluminum-zinc-silicon alloy powder raw material, 0.1Kg of polyvinyl alcohol, 0.2Kg of calcium stearate, and 120Kg of steel balls and put them into the ball mill. Between 30-40°C, ball mill at a speed of 100r / min for 14 hours to discharge the material, put the ball-milled powder into a polishing machine for polishing, and classify the polished powder to obtain flake-shaped aluminum-zinc-silicon alloy powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com