Rotatable adaptive compensator of coiled tubing test string

A technology of self-adaptive compensation and test tube, applied in measurement, drilling tube, casing and other directions, can solve the problem of cable overstretching and damage, and achieve the effect of preventing strand break and protecting the cable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

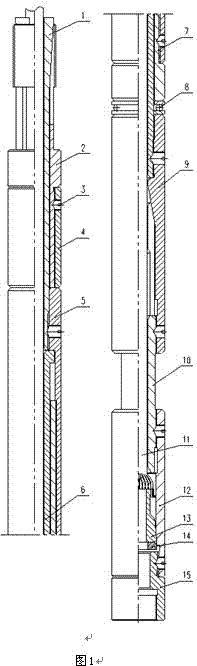

[0020] Further explanation is made below with reference to accompanying drawing:

[0021] according to figure 1 As shown, the coiled tubing test string can rotate the self-adaptive compensator, the coiled tubing slip 2 is sleeved on the locking mandrel 1 from the bottom, the lower part is threaded with the slip locking sleeve 4, and the anti-loosening shear nail 3 fixed, the compensation sleeve 5 is threadedly connected to the lower end of the locking mandrel 1, and fixed with anti-loosening shear nails, the compensation mandrel 6 is inserted into the compensation sleeve 5, and contacts the locking mandrel 1, and the compensation The joint 7 is inserted into the annular space between the compensating mandrel 6 and the compensating sleeve 5, and is threadedly connected with the compensating sleeve 5, and fixed with anti-loosening shear nails, and the cable locking sleeve 9 is threaded with the compensating mandrel 6, and used The anti-loosening shear pin is fixed, the one-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com