Method for manufacturing flexible oil pumping rope

A manufacturing method and oil pumping technology, which can be applied to auxiliary equipment for rope making, cable/conductor manufacturing, textile and paper making, etc., can solve the problems of easily damaged protective layer, low strength and friction, environmental pollution, etc., and prevent strand breakage. , prolong the service life, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Manufacture of sealed steel rope

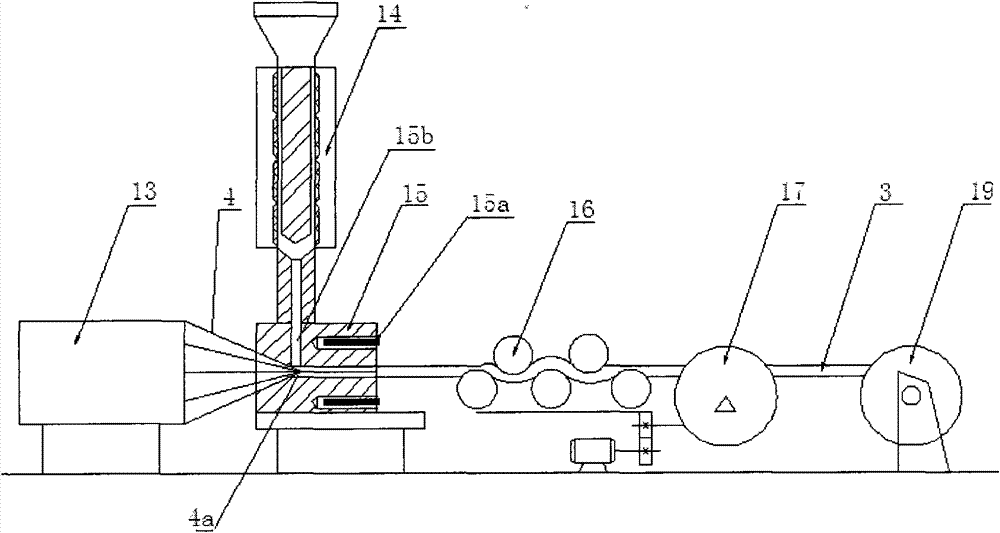

[0036] Such as figure 1 The manufacturing process flow chart of the sealing steel rope of the present invention is shown in the flow chart.

[0037] First, a plurality of steel wire strands 4 are twisted into steel ropes by using a twisting machine 13, and a temperature-controlled crimping die 15 is provided at the junction point 4a of twisting, and a temperature-controlled crimping die 15 is provided with a material injection hole 15b. A filling machine 14 is arranged above it, and the filling machine 14 is connected with the injection hole 15b, so that the filling machine 14 injects the filler into the twisted joint point 4a through the injection hole 15b, and at the same time, through the temperature control pressure line The heating body 15a on the mold 15 heats the joint point 4a, so that the poured filler can reach a viscous state, so that the filler can fill the gap space inside the steel wire strand, thereby forming a seale...

Embodiment 2

[0059] 1. Preparation of communication wires

[0060] The multi-strand copper wire conductor is coated with a layer of high-temperature resistant outer protective insulation layer to make a communication wire. Among them, the communication wire requires low resistivity, high temperature resistance of the outer sheath, high tensile strength, good resistance to fracture or insulation during the stretching process, and reliable working stability.

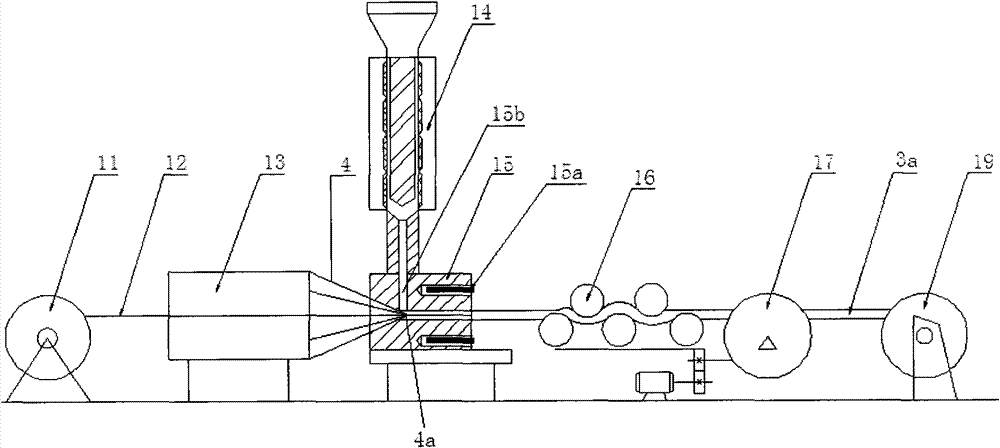

[0061] 2. Manufacture of sealed steel rope

[0062] Such as Figure 1a As shown, the communication wire 9 prepared in step 1 is twisted into a communication cable strand 5, and the communication cable strand 5 is passed through the twisting machine 13, so that the communication cable strand 5 is twisted together with the multi-strand steel wire strand 4, and the rest The process is the same as that in Embodiment 1 to prepare the sealing steel rope 3a, and make the communication cable strand 5 located at the core of the sealing steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com