Patents

Literature

39results about How to "Good bonding surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

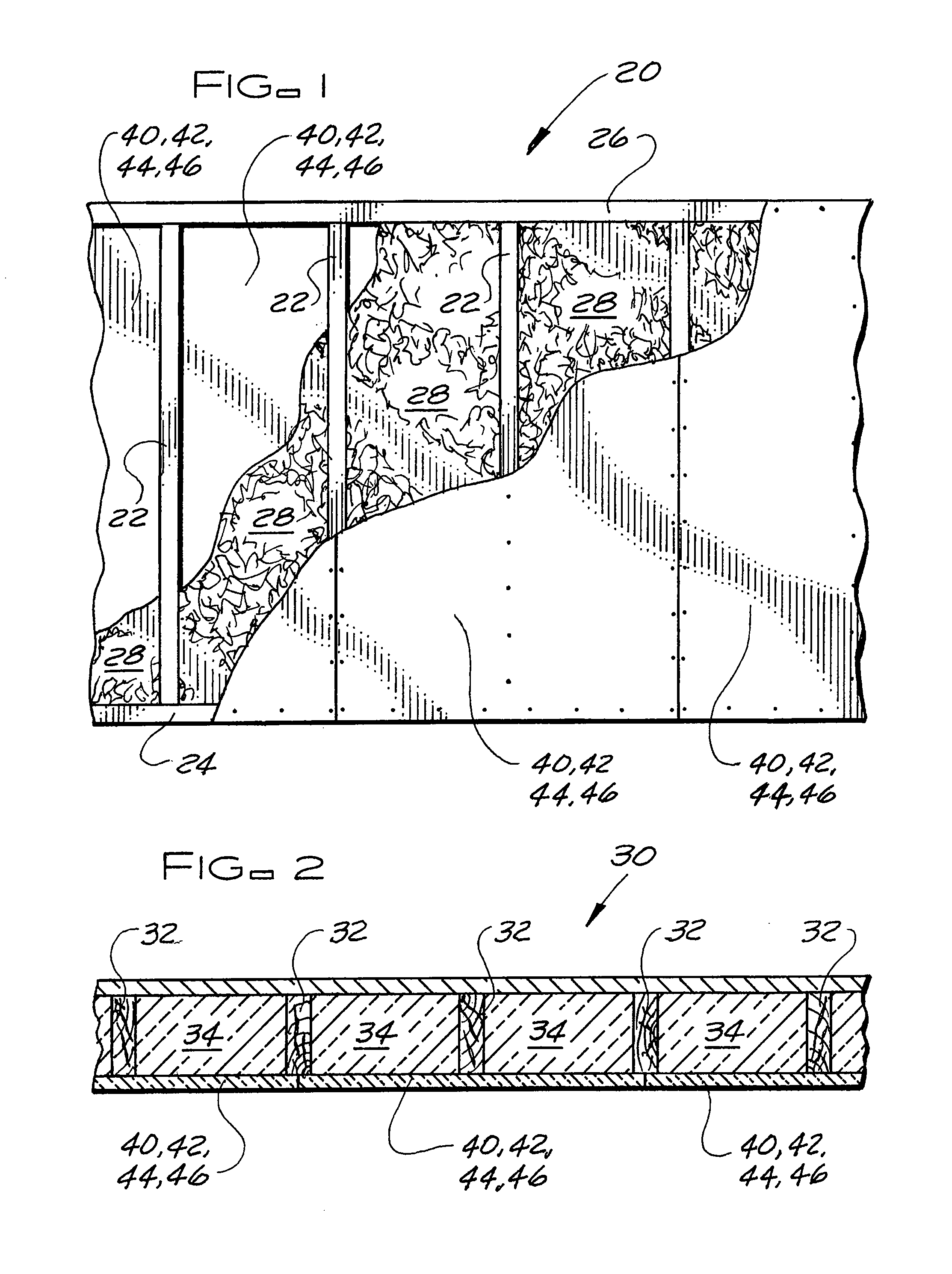

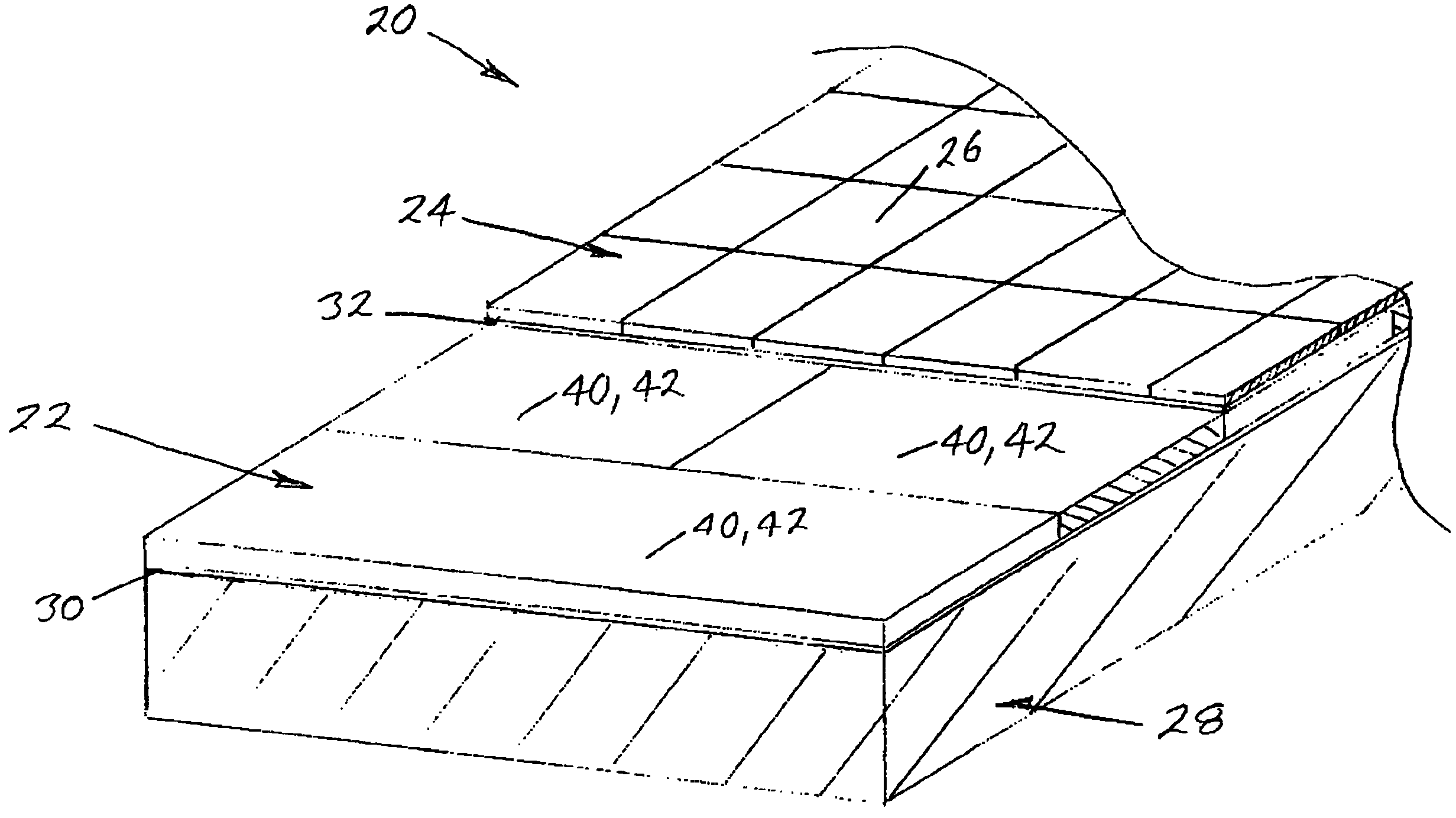

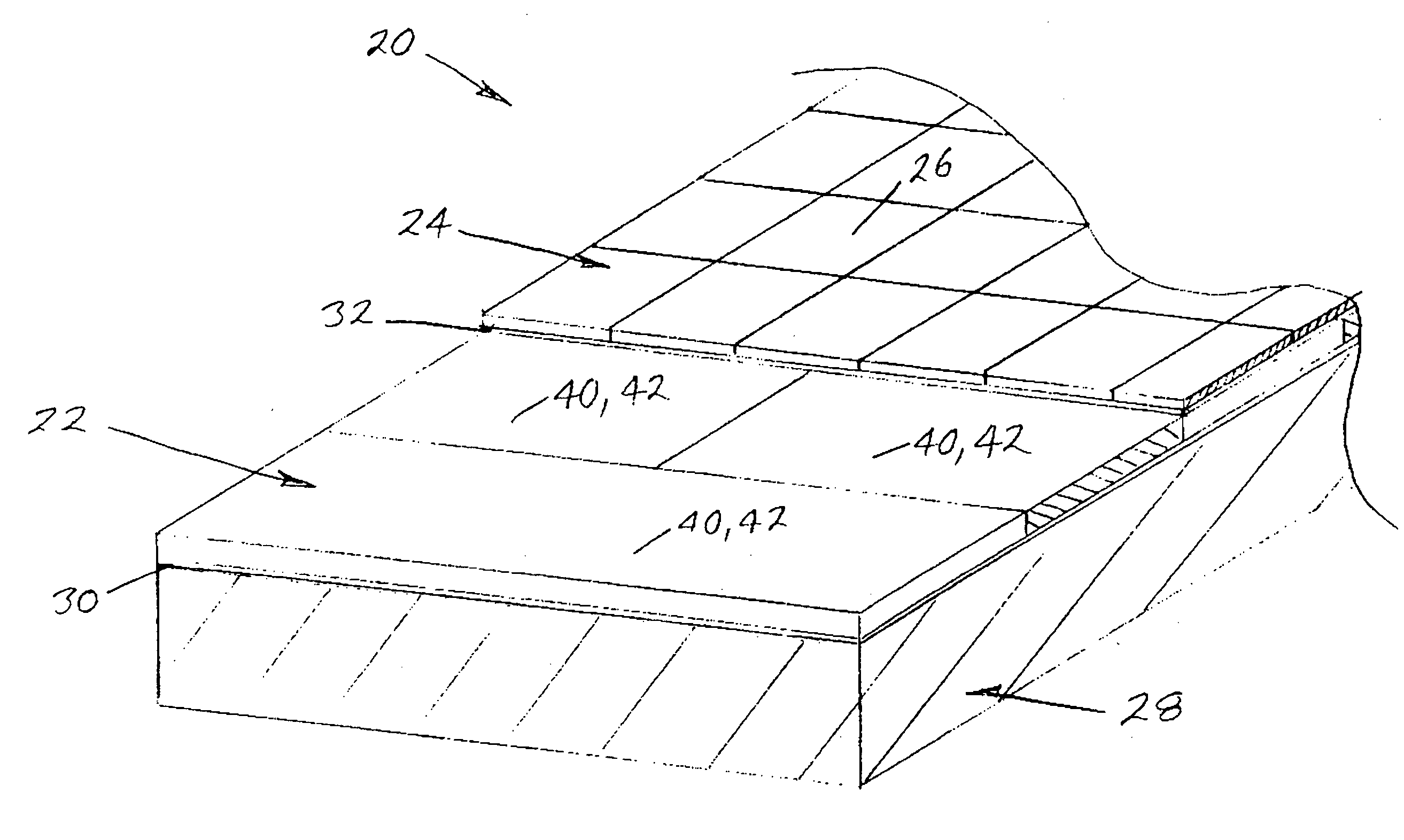

Polymer-based composite structural sheathing board and wall and/or ceiling system

ActiveUS7765761B2Improve integrityAdd dimensionCeilingsCovering/liningsUltimate tensile strengthPolymer chemistry

A wall and / or ceiling polymer-based composite structural sheathing board has a polymer material or predominantly polymer material core layer with a density between 1.6 lbs / ft3 and 25 lbs / ft3. A facer overlays at least one of the major surfaces of the core layer. The facer is generally coextensive with and bonded to the overlaid major surface of the core layer and enhances the integrity and fastener pull through strength of the polymer-based composite structural sheathing board as well as other desired physical and performance characteristics of the polymer based composite structural sheathing board. A wall and / or ceiling system of a building structure includes a plurality of the polymer-based composite structural sheathing boards overlaying and secured to a structural wall and / or ceiling frame and forming a wall and / or ceiling sheathing layer over the structural frame.

Owner:JOHNS MANVILLE CORP

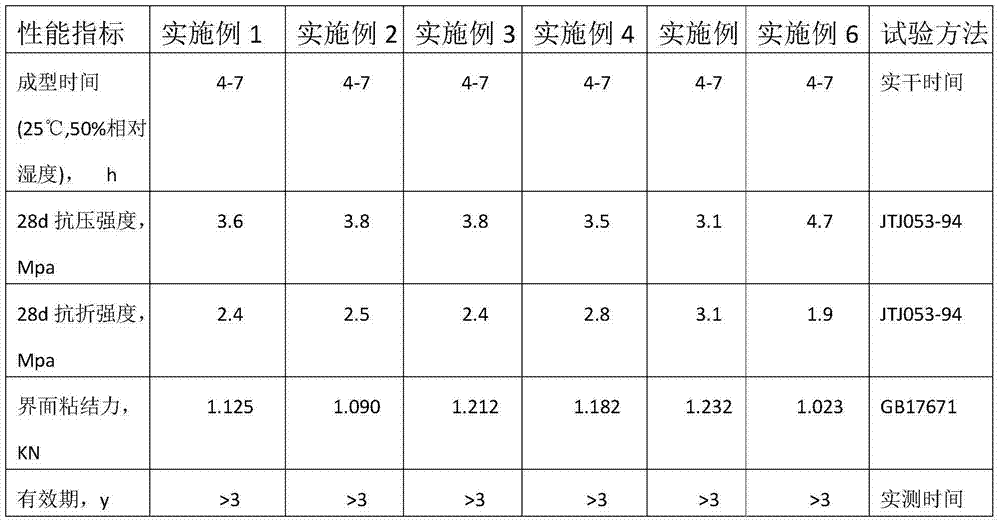

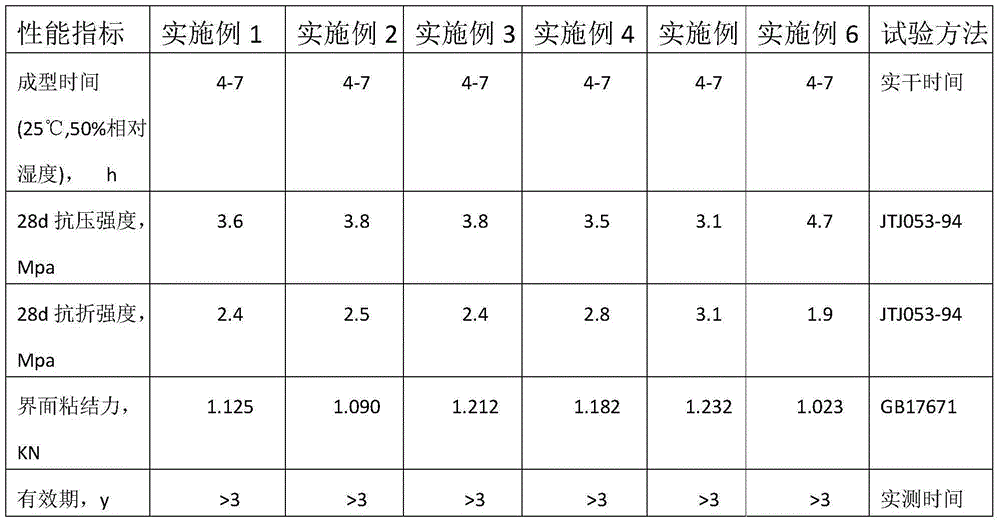

Asphalt base composite material for pavement crack repair

The invention discloses an asphalt base composite material for pavement crack repair. The asphalt base composite material for pavement crack repair is prepared from a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 120-150 parts of anionic emulsified asphalt, 1-3 parts of water reducing agent, 1-3 parts of defoaming agent, 3-8 parts of binder and 0-10 parts of water, and the component B comprises the following raw materials in parts by weight: 100 parts of cement, 70-110 parts of sand and 0.01-0.06 part of expanding agent. The asphalt base composite material for pavement crack repair has the flexibility of asphalt, the rigidity of cement and certain strength, is used for crack pouring and can bear and transfer loading force; the binder is added to the material so as to play a role of reinforcing the binding force between the material and crack walls, so that the service life of a pavement is prolonged, and the re-cracking phenomenon is difficult to occur. The asphalt base composite material for pavement crack repair has the advantages of low cost price, simple construction, low requirements on constructors, low energy consumption, low cost, strong binding power and long useful life and can be widely applied to the pavement crack repair.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

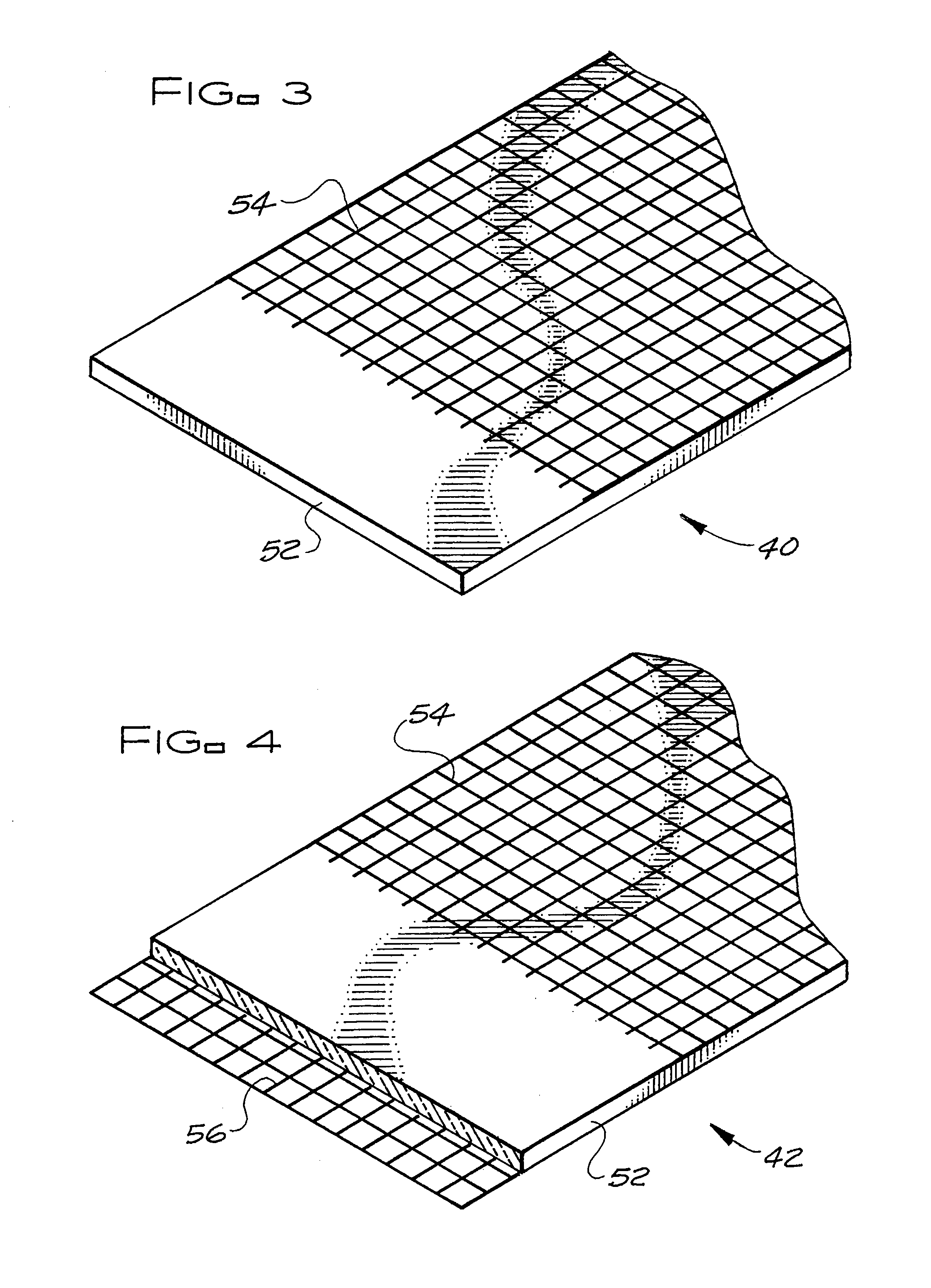

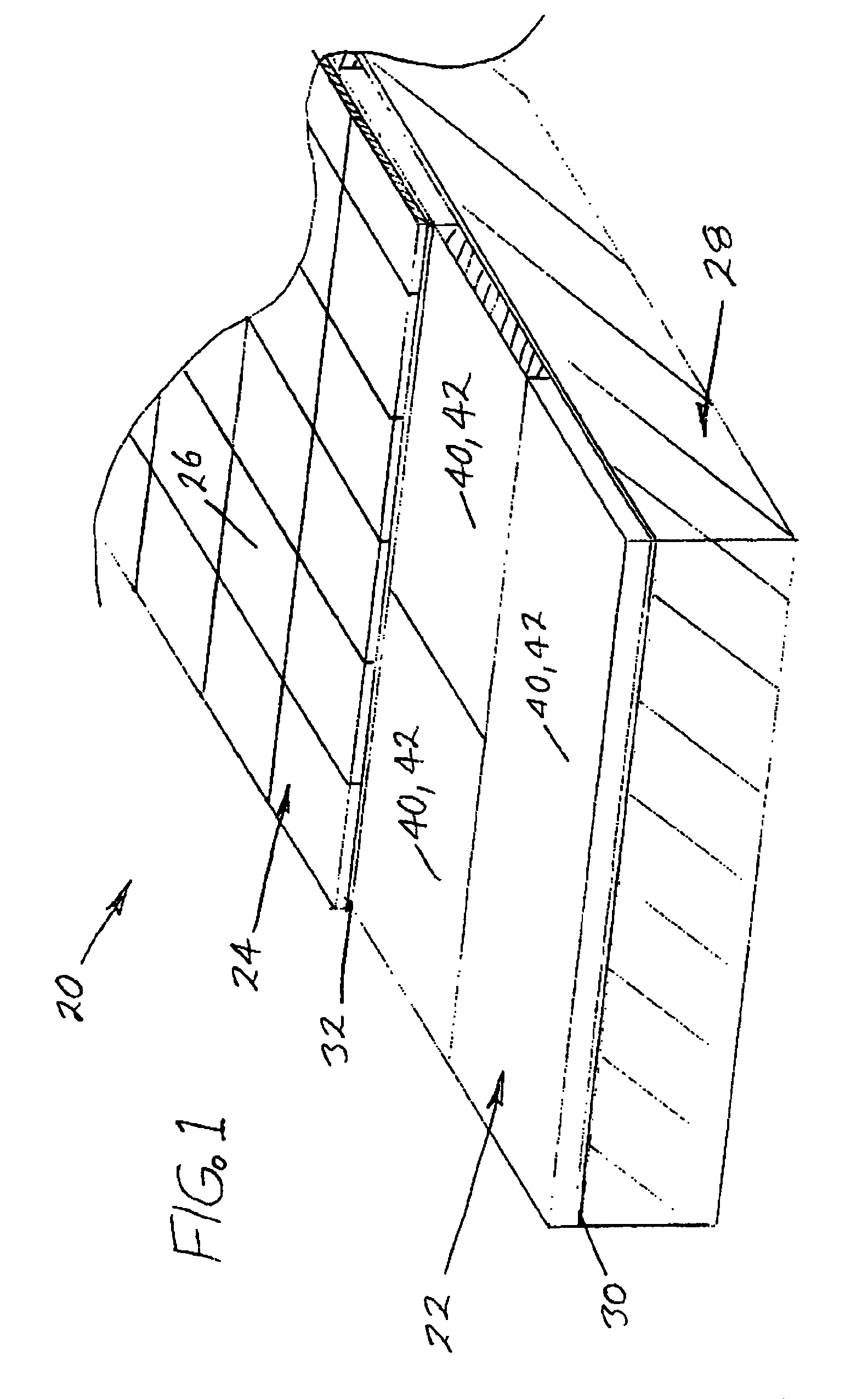

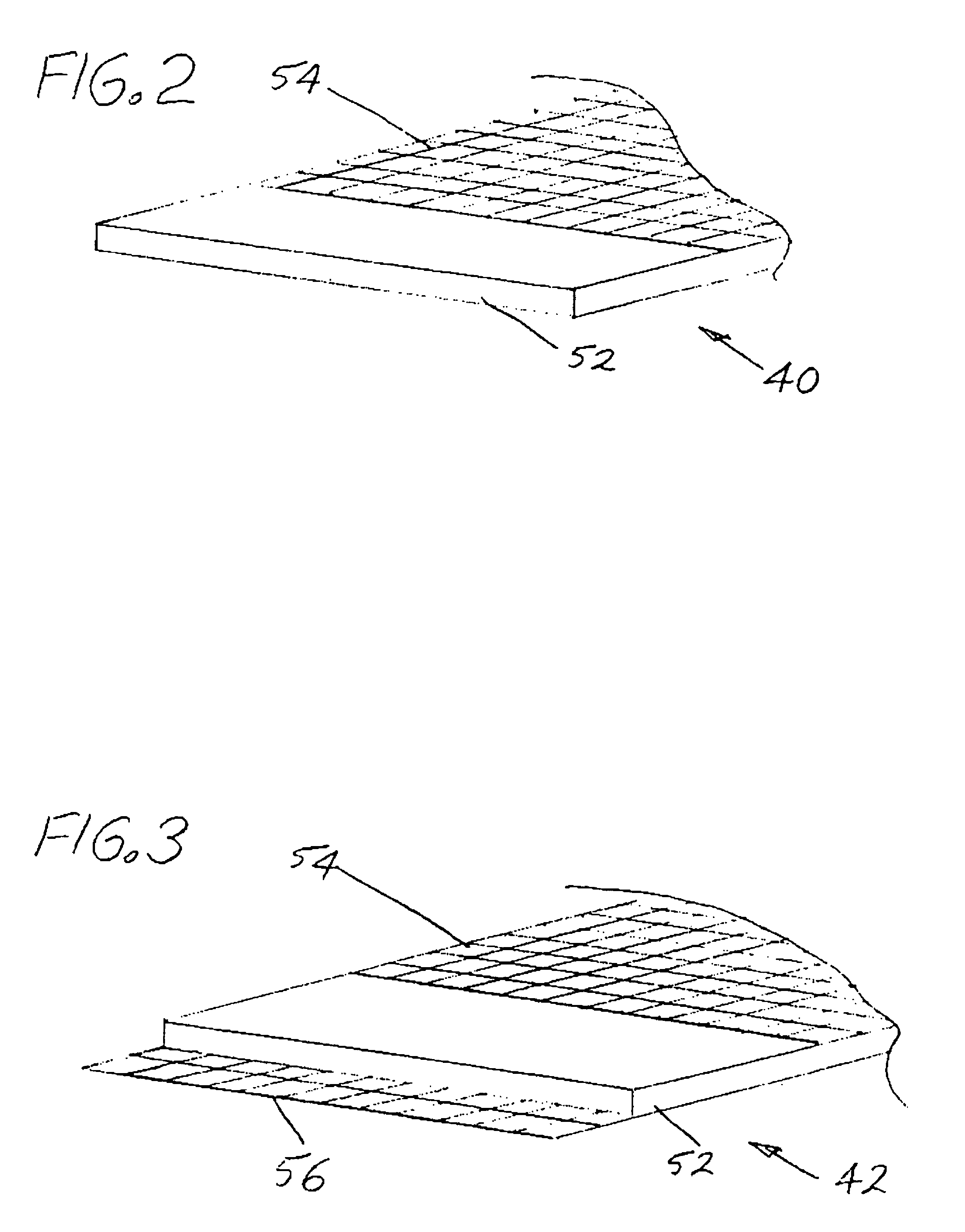

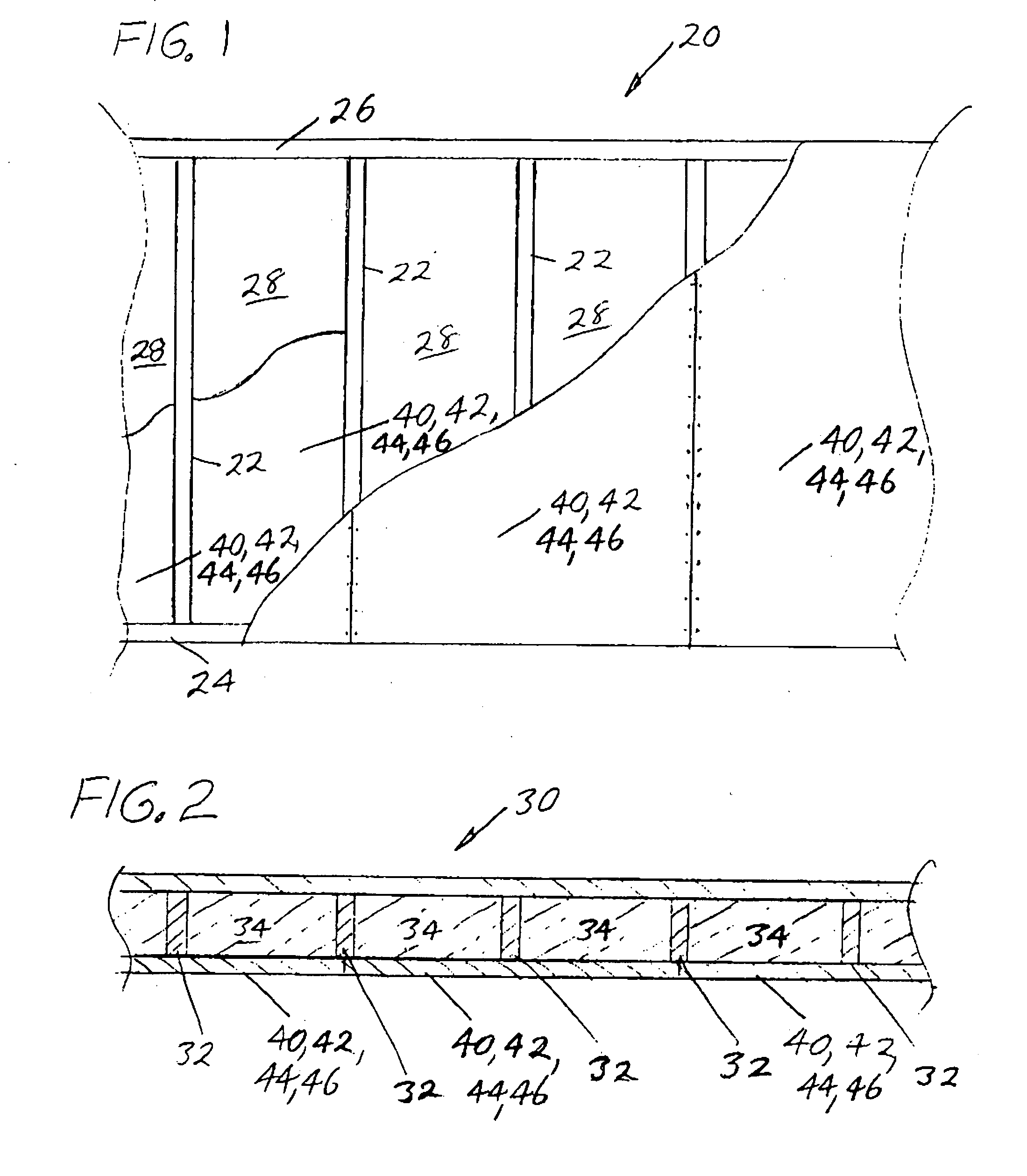

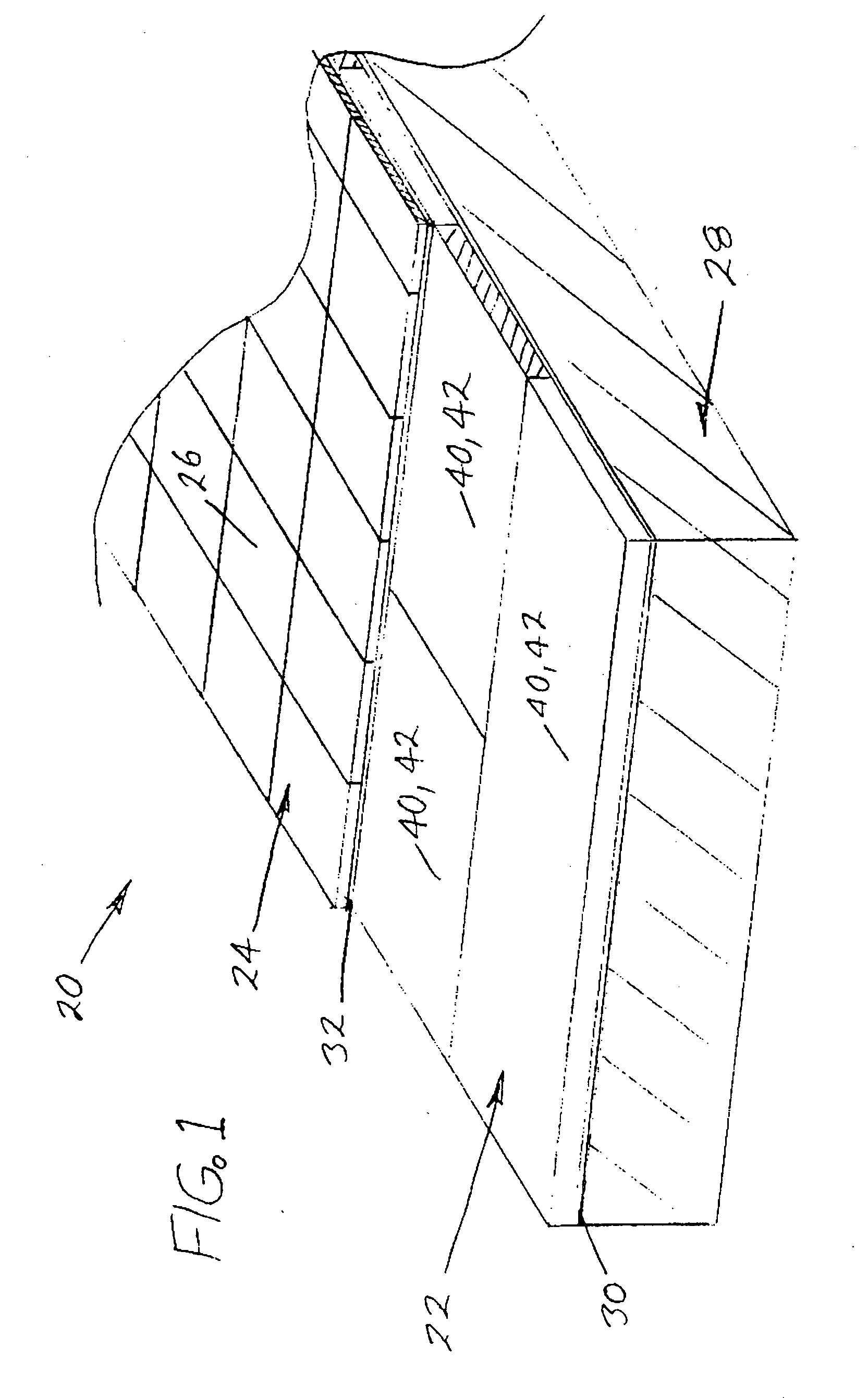

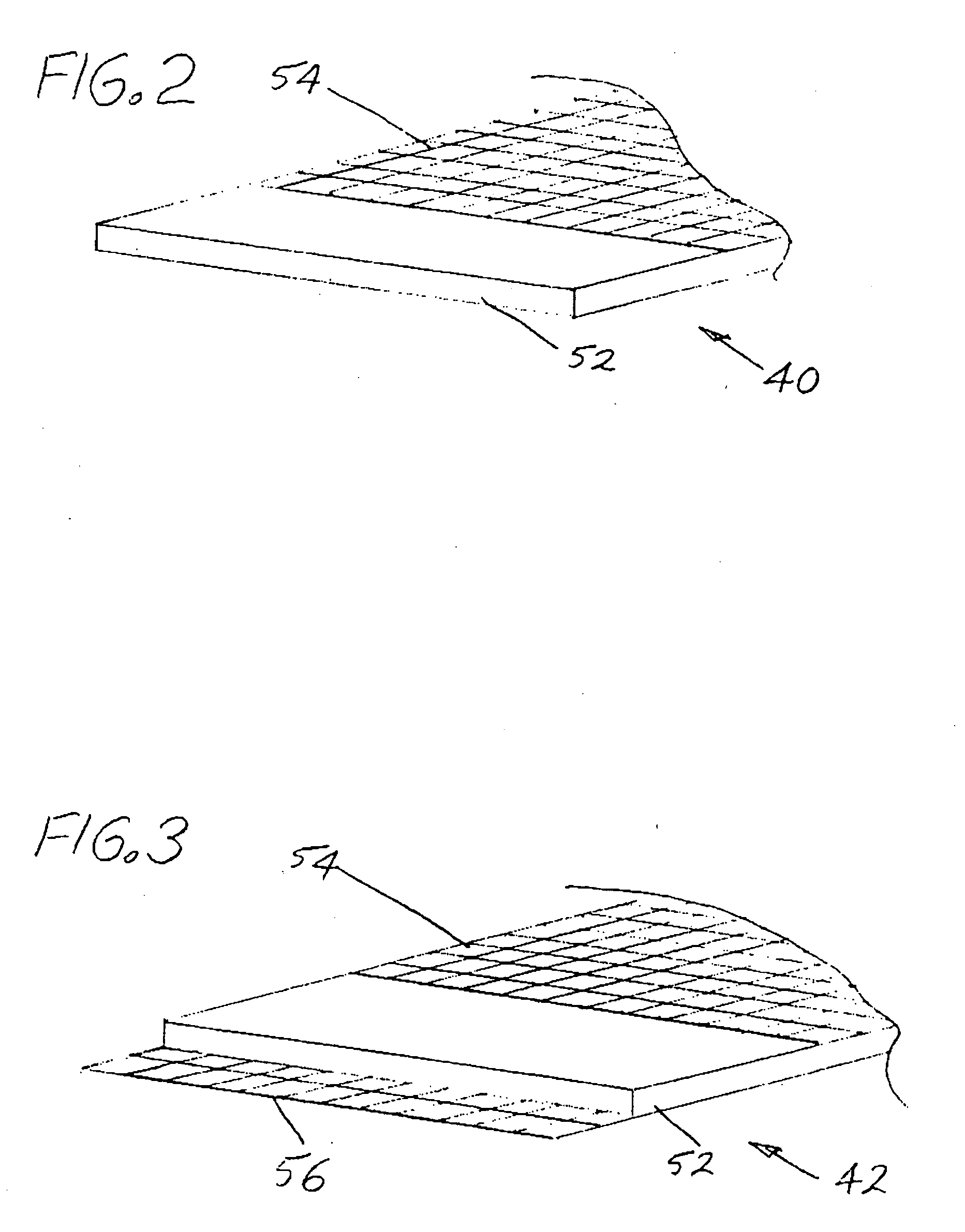

Polymer-based composite structural underlayment board and flooring system

ActiveUS7735279B2Good dimensional stabilityLight weightCeilingsFloorsCompound structurePolymer chemistry

A building flooring system includes a plurality of polymer-based composite structural underlayment boards overlaying and secured to a building subfloor to form an underlayment layer over the building subfloor and a nonstructural finish-flooring layer overlaying and bonded to the underlayment layer. The polymer-based composite structural underlayment boards each have a polymer material core layer or a predominantly polymer material core layer that typically contains from 1% to 40% by weight filler(s) and a density between 1.6 lbs / ft3 and 25 lbs / ft3. At least the top or bottom major surface of each of the polymer-based composite structural underlayment boards is overlaid by a facer that reinforces and strengthens the polymer-based composite structural underlayment board and that is generally coextensive with and bonded to the overlaid major surface of the polymer-based composite structural underlayment board.

Owner:JOHNS MANVILLE CORP

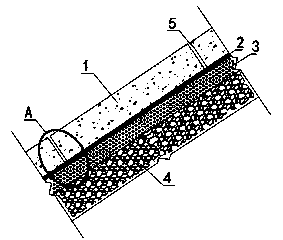

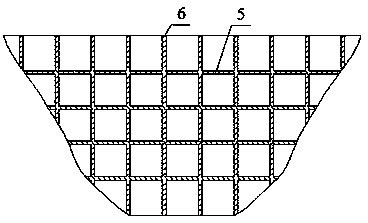

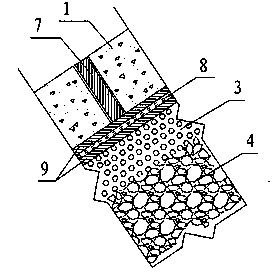

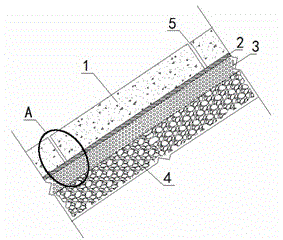

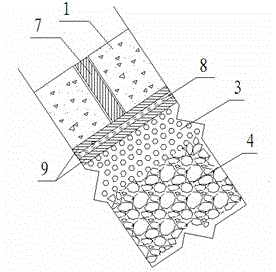

High rock-fill dam membrane anti-seepage body on deep coverage layer and construction method of high rock-fill dam membrane anti-seepage body

InactiveCN103643656AStrong adaptability to deformationNo crackEarth-fill damsRock-fill damsOverburdenFiber

The invention discloses a high rock-fill dam membrane anti-seepage body on a deep coverage layer and a construction method of the high rock-fill dam membrane anti-seepage body. The membrane anti-seepage body is composed of a concrete protection layer, a geomembrane anti-seepage layer, a flexibility cushion layer and a transition layer. The concrete protection layer is a cast-in-place fiber concrete layer for a reserved cross joint and a vertical joint and located on a surface layer to protect a geomembrane. The geomembrane anti-seepage layer is a two-cloth and one-membrane composite geomembrane and is located in the middle to play a role of preventing seepage. The flexibility cushion layer is a polyurethane pervious concrete layer and located at the bottom of the anti-seepage body to support the geomembrane and to transmit and disperse water loads. The rough granule transition layer is arranged between the flexibility cushion layer and a rock-fill dam body. The construction method comprises the technical steps of filling and building the transition layer, pouring the flexibility cushion layer, paving the composite geomembrane, pouring the concrete protection layer and the like. The membrane anti-seepage body can keep stable on a high rock-fill dam slope, the ability of adapting to deformation of a coverage layer dam foundation and the dam body is high, the structural form is simple, construction is fast, and the anti-seepage problem of the high rock-fill dam on the deep coverage layer can be effectively solved.

Owner:HOHAI UNIV

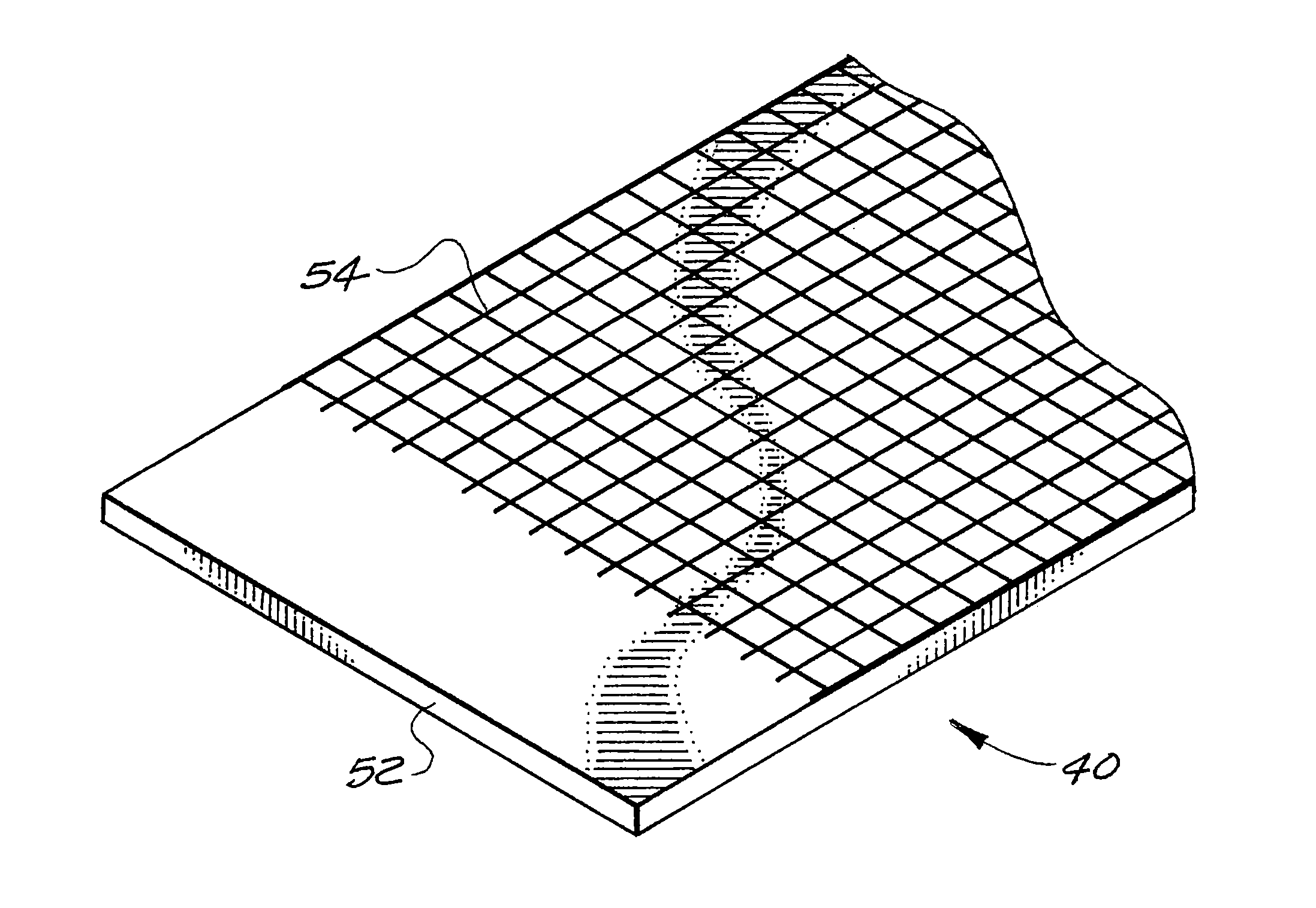

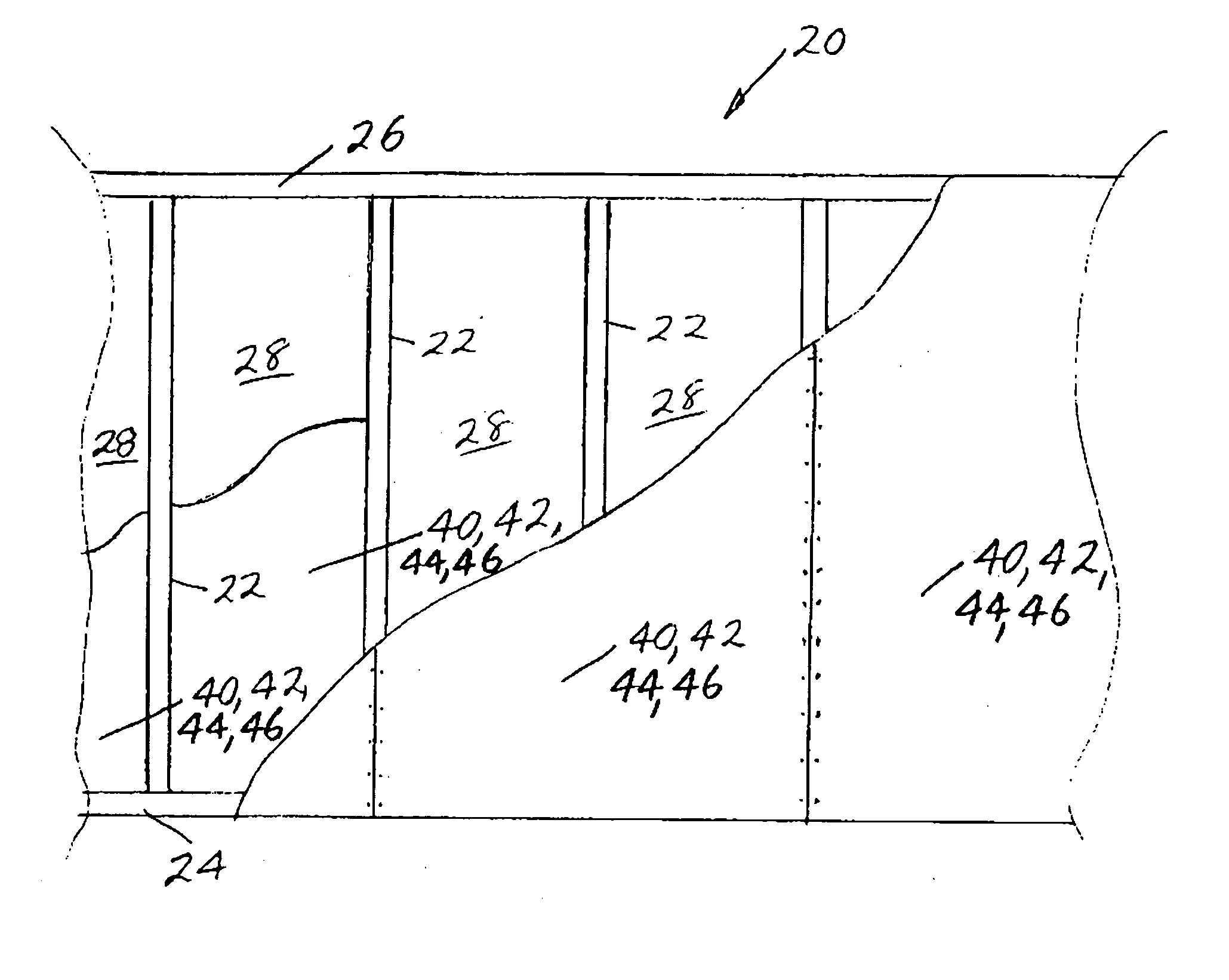

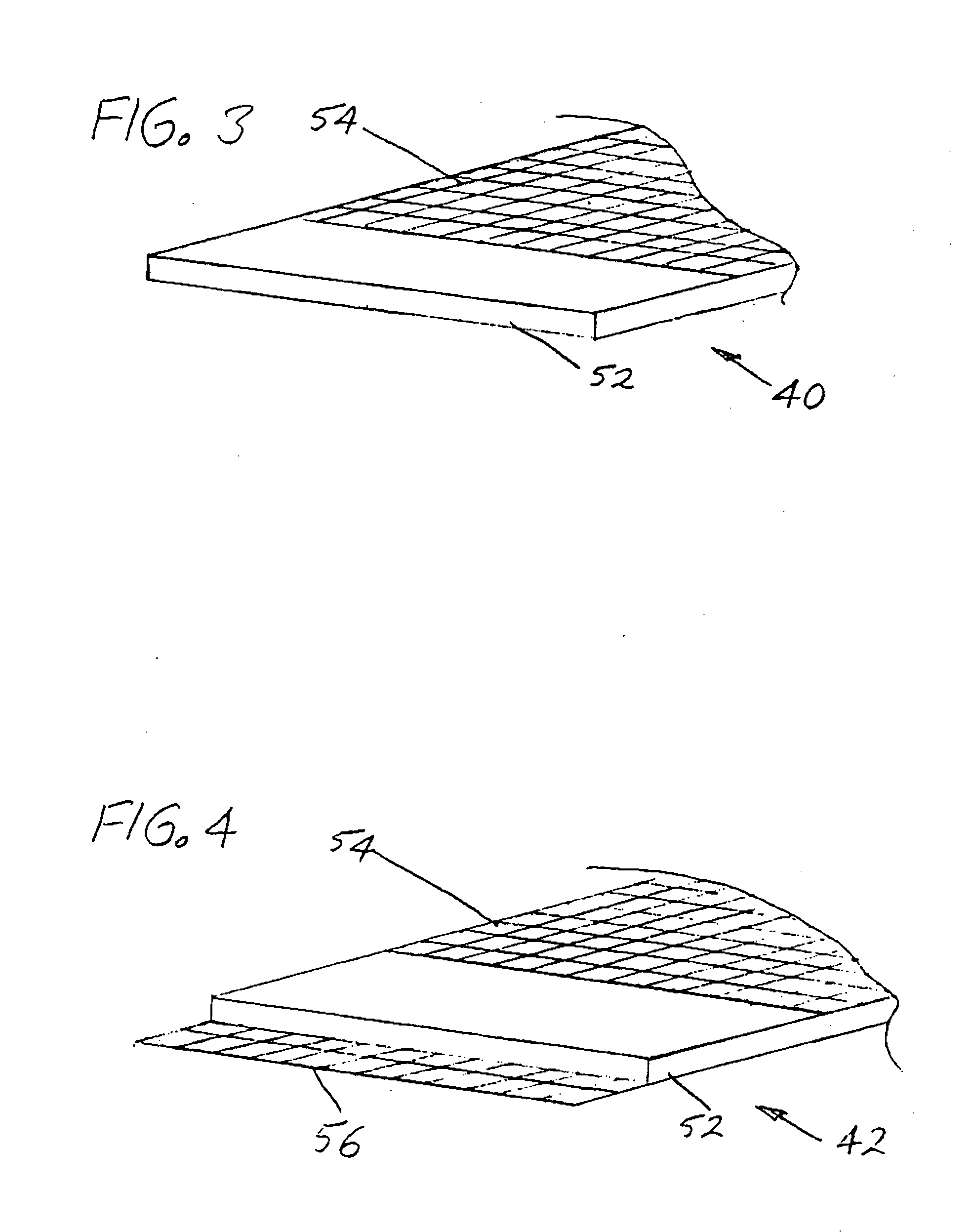

Polymer-based composite structural sheathing board and wall and/or ceilling system

ActiveUS20080120932A1Good dimensional stabilityGood bonding surfaceCeilingsConstruction materialFastenerPolymer chemistry

A wall and / or ceiling polymer-based composite structural sheathing board has a polymer material or predominantly polymer material core layer with a density between 1.6 lbs / ft3 and 25 lbs / ft3. A facer overlays at least one of the major surfaces of the core layer. The facer is generally coextensive with and bonded to the overlaid major surface of the core layer and enhances the integrity and fastener pull through strength of the polymer-based composite structural sheathing board as well as other desired physical and performance characteristics of the polymer based composite structural sheathing board. A wall and / or ceiling system of a building structure includes a plurality of the polymer-based composite structural sheathing boards overlaying and secured to a structural wall and / or ceiling frame and forming a wall and / or ceiling sheathing layer over the structural frame.

Owner:JOHNS MANVILLE CORP

Polymer-based composite structural underlayment board and flooring system

ActiveUS20080124530A1Good dimensional stabilityLight weightCeilingsFloorsComposite constructionVolumetric Mass Density

A building flooring system includes a plurality of polymer-based composite structural underlayment boards overlaying and secured to a building subfloor to form an underlayment layer over the building subfloor and a nonstructural finish-flooring layer overlaying and bonded to the underlayment layer. The polymer-based composite structural underlayment boards each have a polymer material core layer or a predominantly polymer material core layer that typically contains from 1% to 40% by weight filler(s) and a density between 1.6 lbs / ft3 and 25 lbs / ft3. At least the top or bottom major surface of each of the polymer-based composite structural underlayment boards is overlaid by a facer that reinforces and strengthens the polymer-based composite structural underlayment board and that is generally coextensive with and bonded to the overlaid major surface of the polymer-based composite structural underlayment board.

Owner:JOHNS MANVILLE CORP

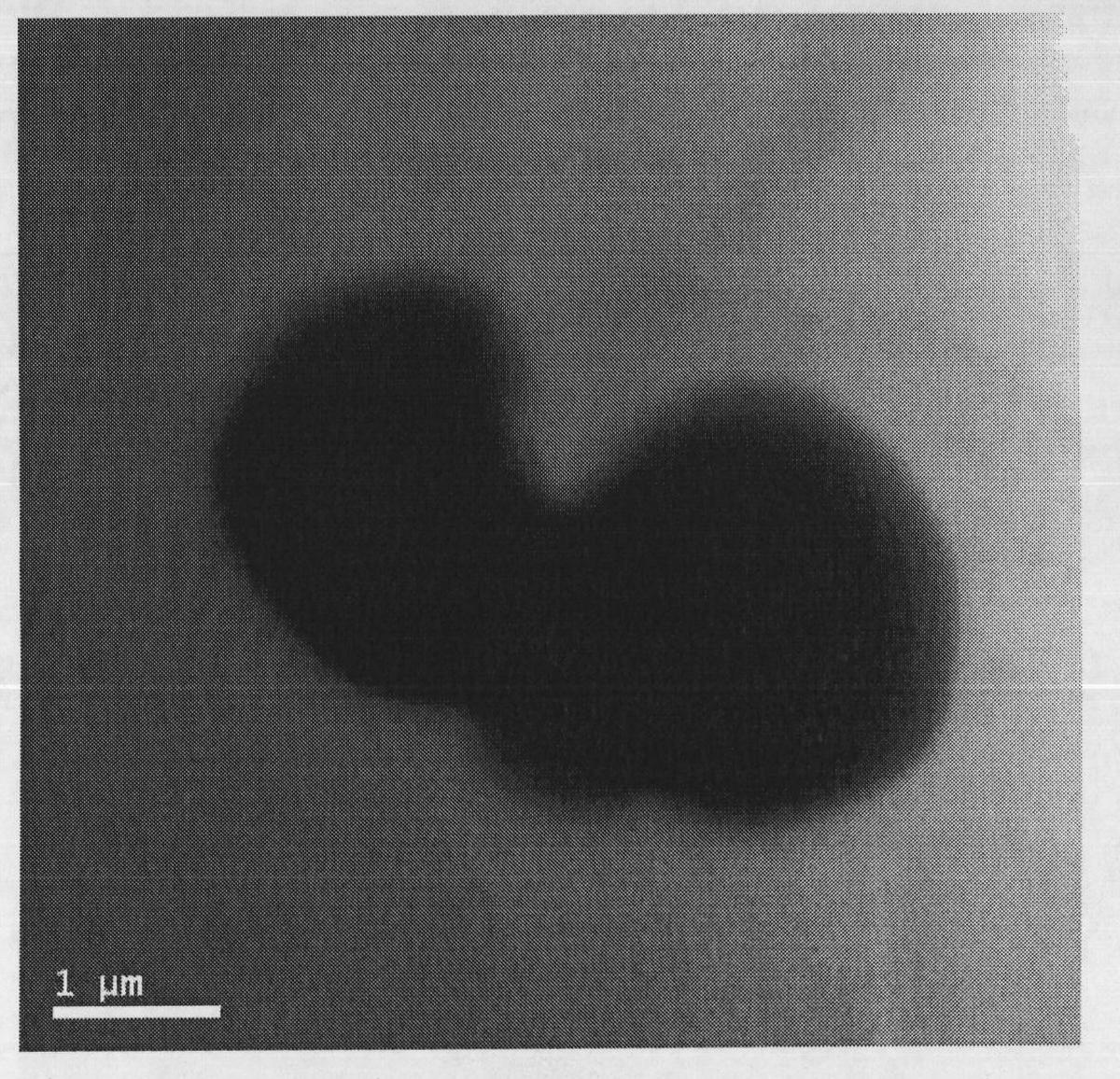

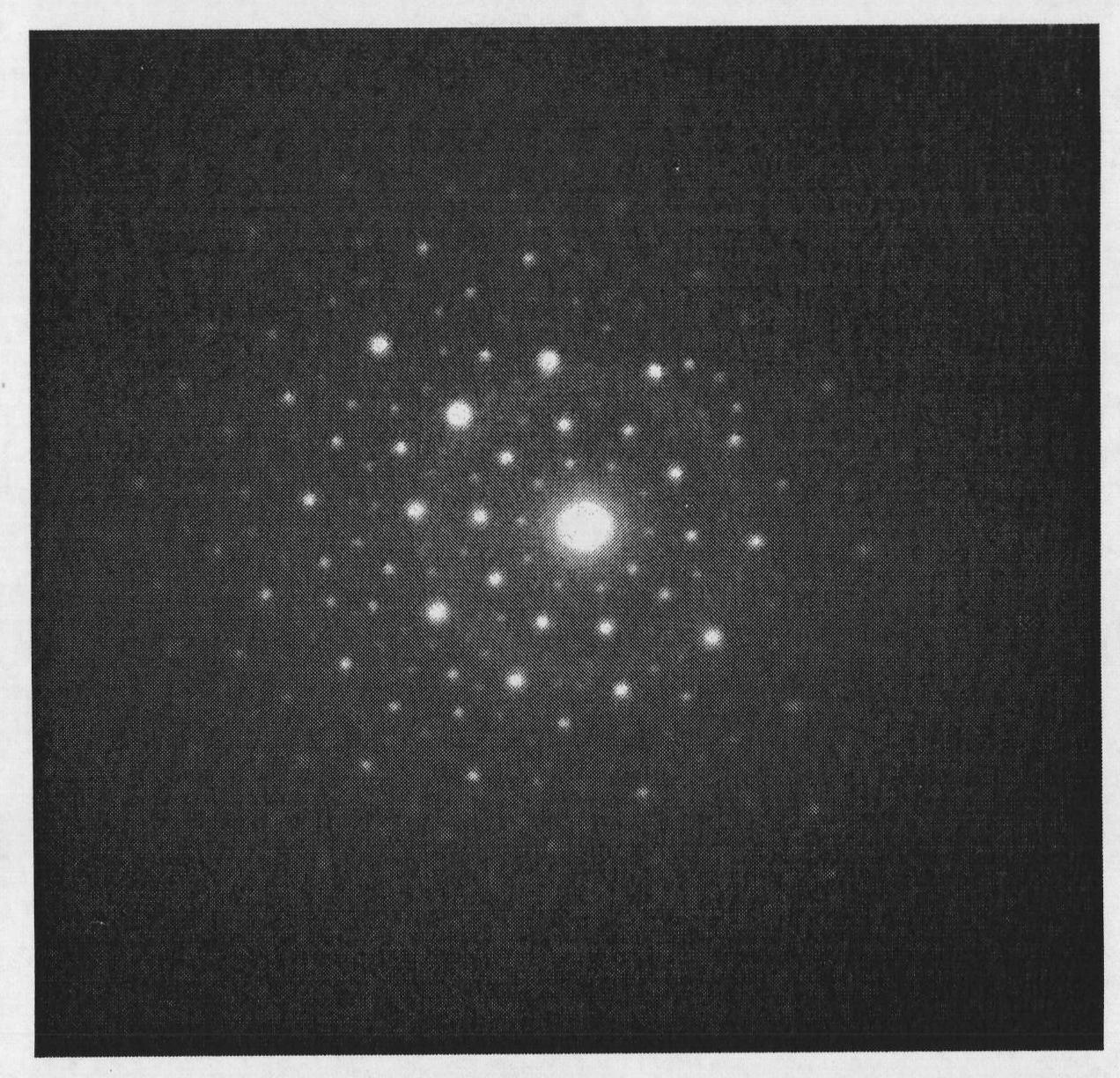

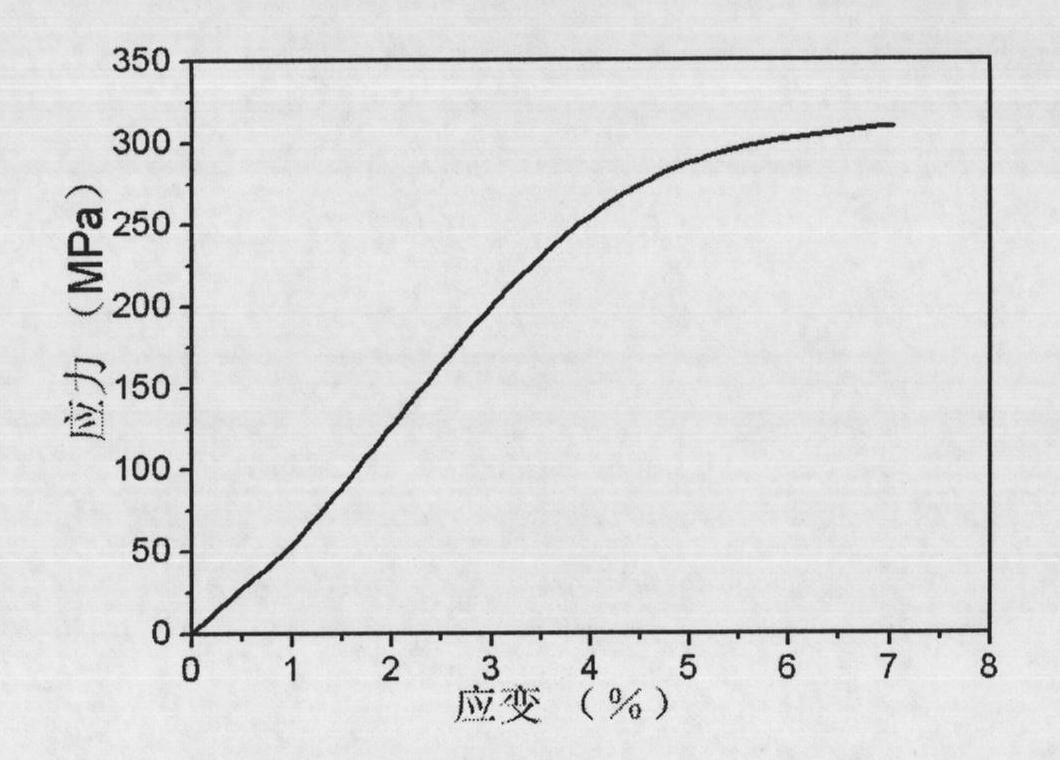

Quasicrystal particle reinforced magnesium matrix composite material and preparation method thereof

InactiveCN101787475AAvoid poor wettabilityAvoid different coefficients of expansionOptimal combinationQuasicrystal

The invention discloses a quasicrystal particle reinforced magnesium matrix composite material and a preparation method thereof. The composite material matrix is industrial pure magnesium; the reinforced particle is Mg-Zn-Gd quasicrystal particle, the size of the quasicrystal particle is of 20-100um, and the weight percentage of the quasicrystal particle is of 5-30 percent. The preparation method is as follows: by adopting the repeated plastic deformation technology processing procedure, the proportion of the quasicrystal particles is accurately controlled according to different purposes of the magnesium matrix material, so as to achieve the optimal combination of the intensity and elongation and lead the prepared composite material to meet different needs.

Owner:BEIJING UNIV OF TECH

Spray-seeding planting method for mountain restoration

InactiveCN111096192APurify the initial environmentPromote germinationHops/wine cultivationGrowth substratesPlanting seedNonwoven fabric

The invention relates to a spray-seeding planting method for mountain restoration. The method comprises the following steps: S1, after unstable soil and stones are arranged, fixing a wire mesh to a slope surface by using an anchor rod; S2, spraying slurry to a base layer: spraying a first matrix on the slope surface, so that the first matrix fully fills the space under the mesh to form a first matrix layer; S3, performing surface layer spray-seeding: after the first matrix layer is adhered stably, laying a vegetation mesh, performing soil dressing spray-seeding, so that a second matrix with plant seeds fills pores of the vegetation mesh to form a second matrix layer, wherein the vegetation mesh is degradable, and the plant seeds are subjected to pelleting coating treatment; and S4, performing maintenance management: after spray-seeding, covering the surface with a sunshade mesh or non-woven fabric, performing regular watering, fertilization and insect prevention maintenance, and removing the sunshade mesh or non-woven fabric after the seeds germinate. According to the method provided by the invention, the plant seeds are subjected to coating treatment, so that the initial environment of the growth of the plant seeds is purified, the seed germination is promoted, and the germination rate and the seedling rate of the seeds are improved.

Owner:河南城市园丁园艺有限公司

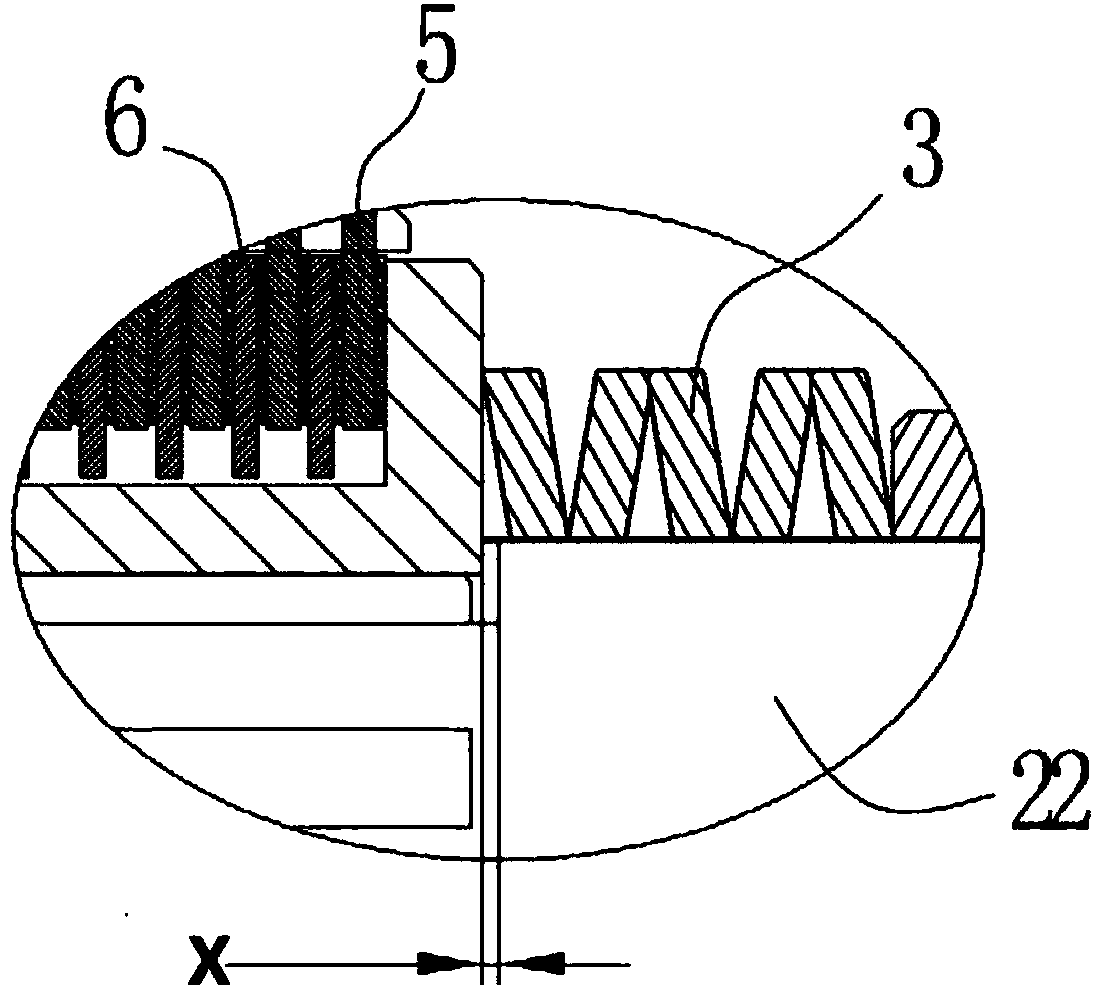

Secondary injection molding process of megawatt level wind turbine blades

ActiveCN102001185AImprove quality and efficiencyIncrease productivityDomestic articlesVacuum pumpingTurbine blade

The invention provides a secondary injection molding process of megawatt level wind turbine blades. When a white spot region is found after the primary resin injection is completed, a circle of spiral pipe is fast paved on the white spot region, a plurality of glue injection nozzles are uniformly distributed on the spiral pipe, and a layer of outer-layer vacuum bag is covered above the white spotregion through sealing joint strips on the periphery of the spiral pipe. Small holes are dug in the middle of the outer-layer vacuum bag above the center of the white spot region, the glue injection pipe is connected with the spiral pipe while gluing a vacuum air suction pipe, a communication pipe with a middle valve is arranged between the vacuum air suction pipe and the glue injection pipe, theother end of the glue injection pipe is connected with a glue injection barrel through a glue injection valve, the outer end of the vacuum air suction pipe is connected with a vacuum pump through a vacuum valve, vacuum pumping and glue injection are carried out after the system pavement is completed, a injected region is heated, and the manufacture is completed after the fiber structure is cured.The secondary injection resin and the primary injection resin have good combining surfaces, the operation is simple, the fiber intensity in each direction is ensured, and the blade quality and the production efficiency are improved.

Owner:中复连众(哈密)复合材料有限公司

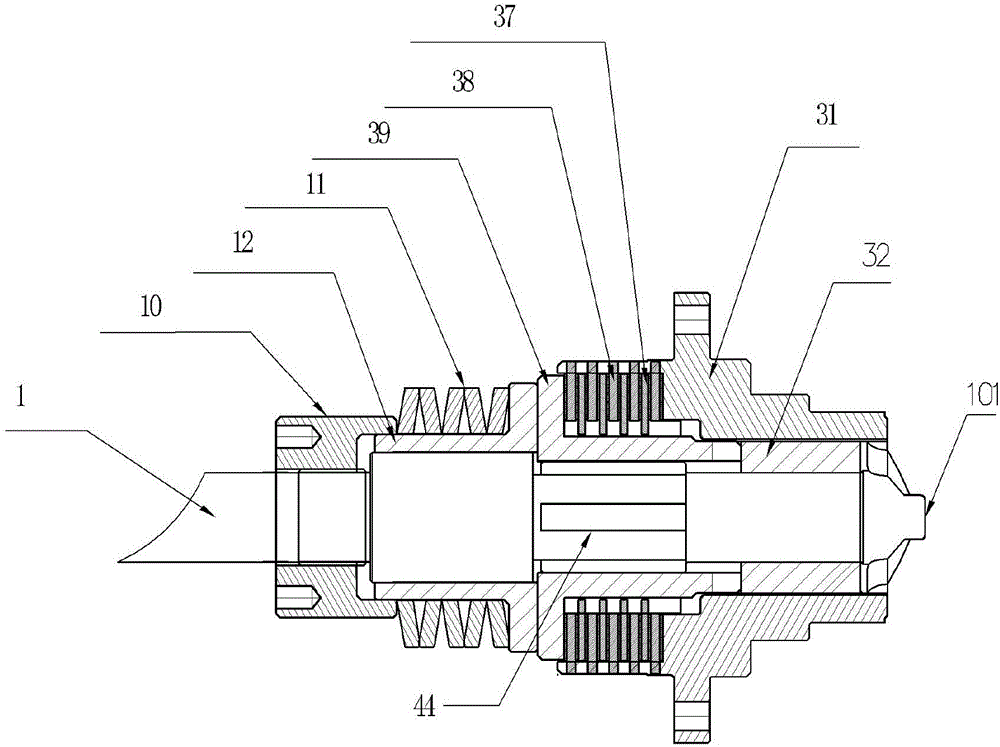

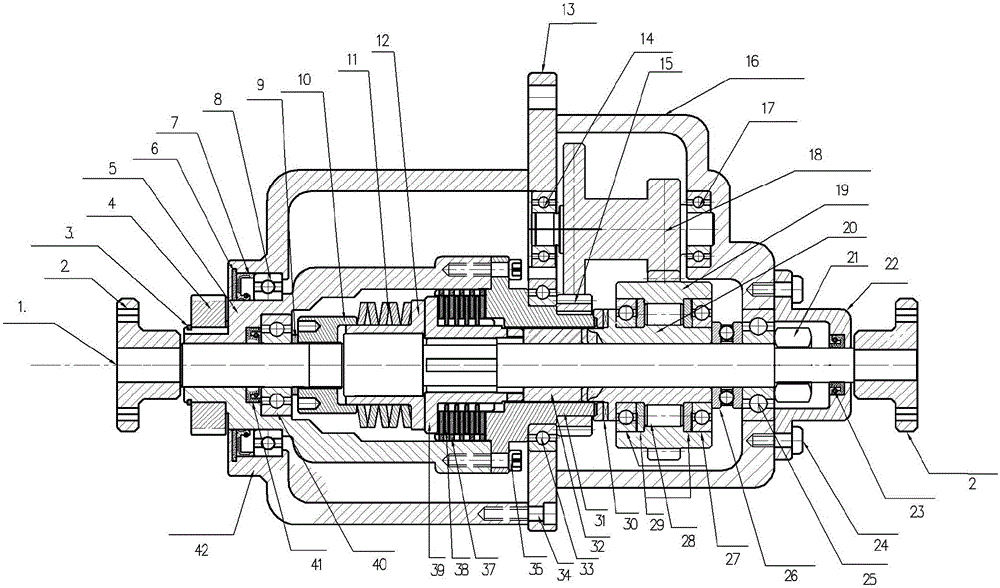

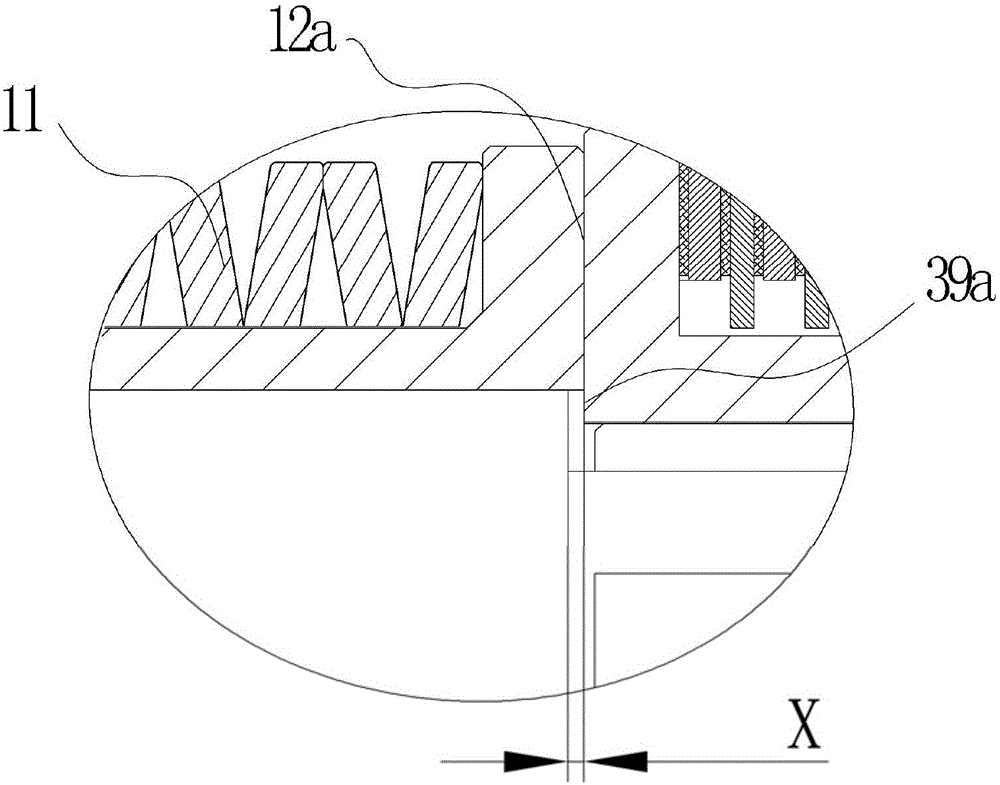

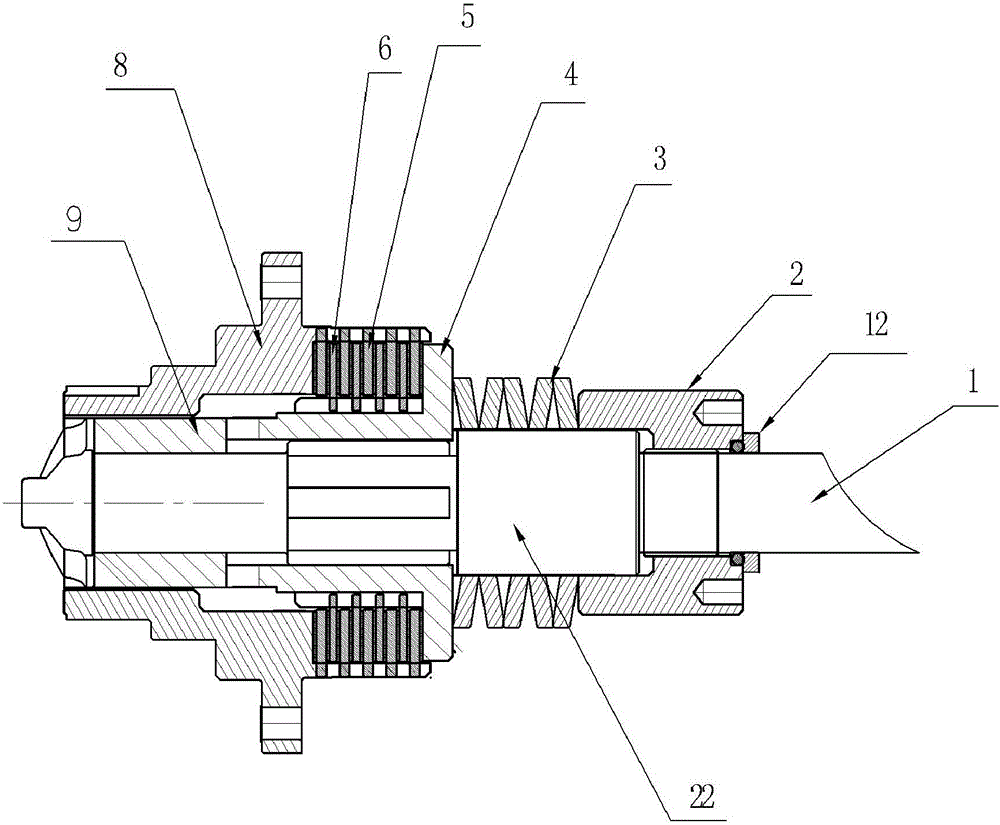

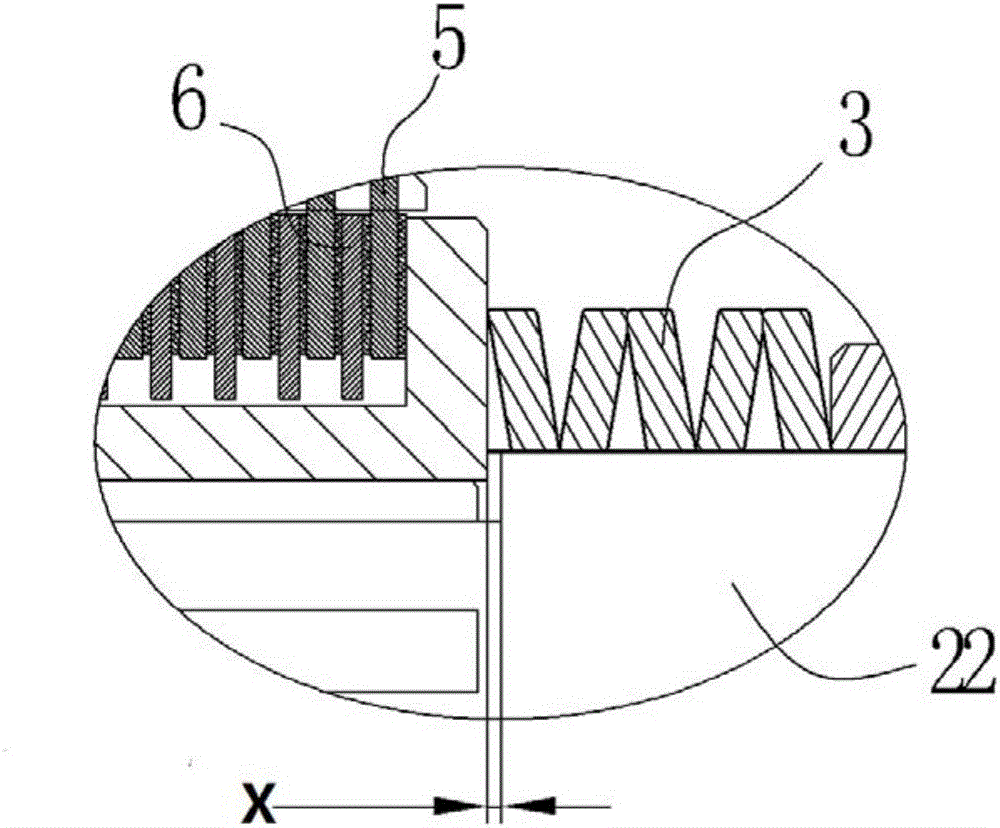

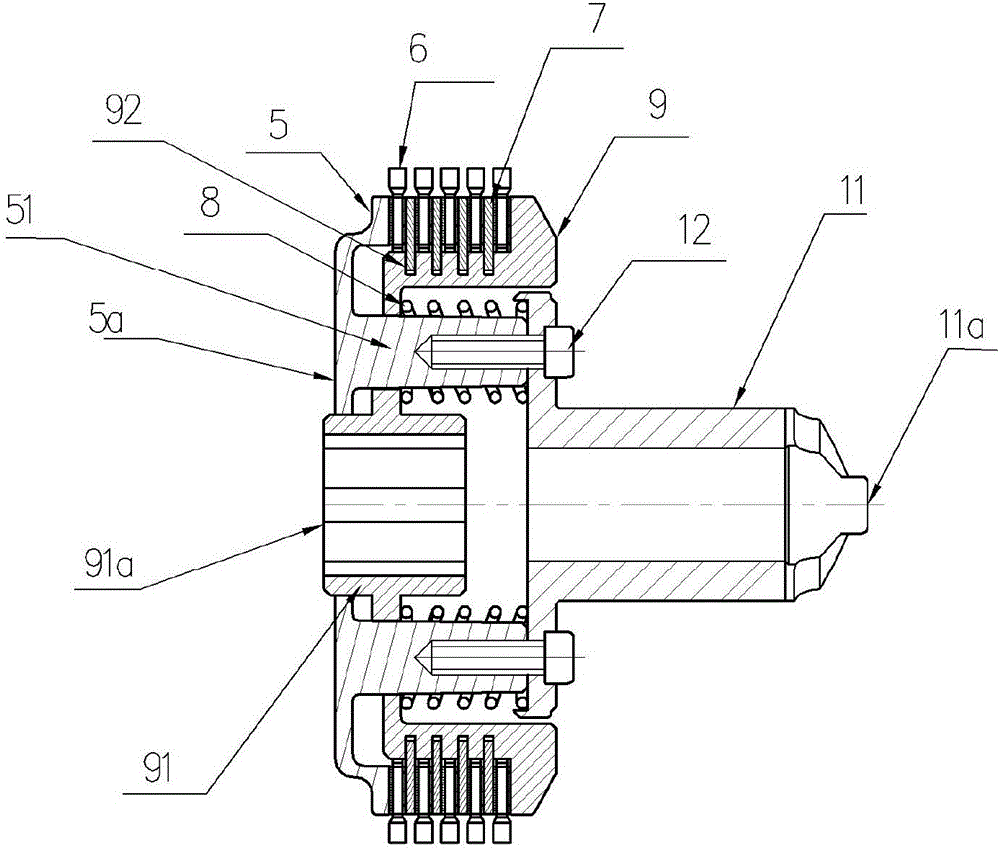

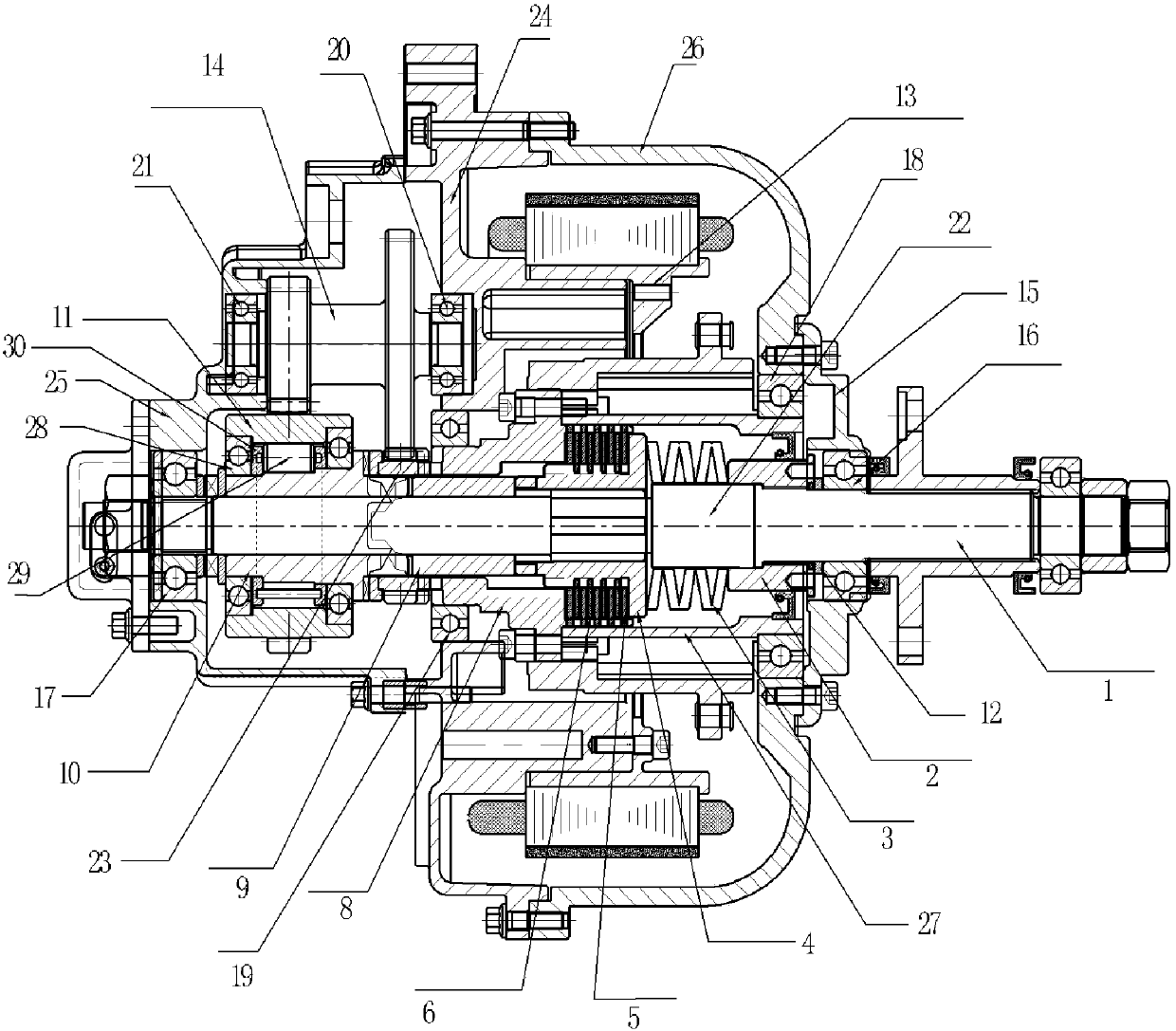

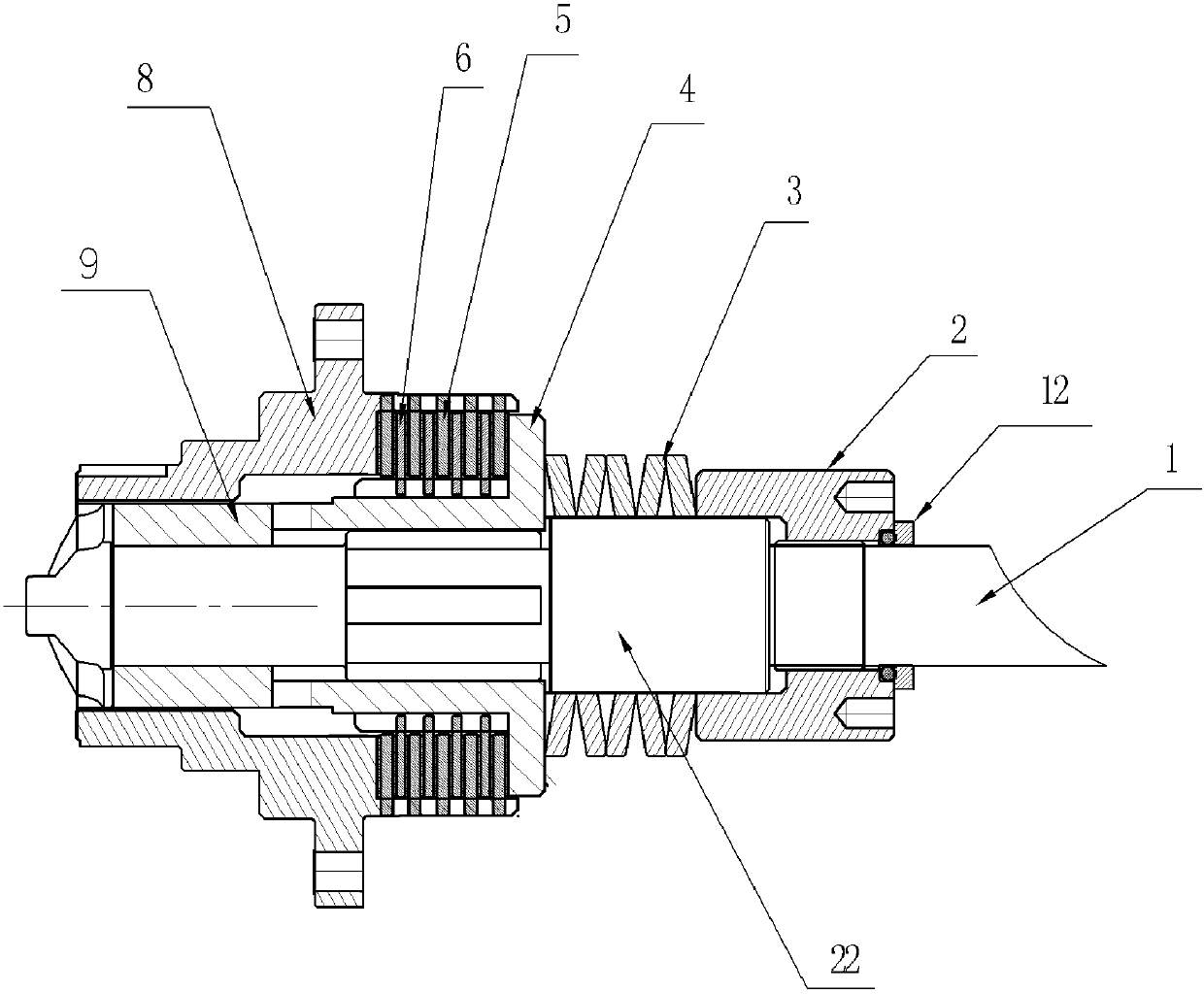

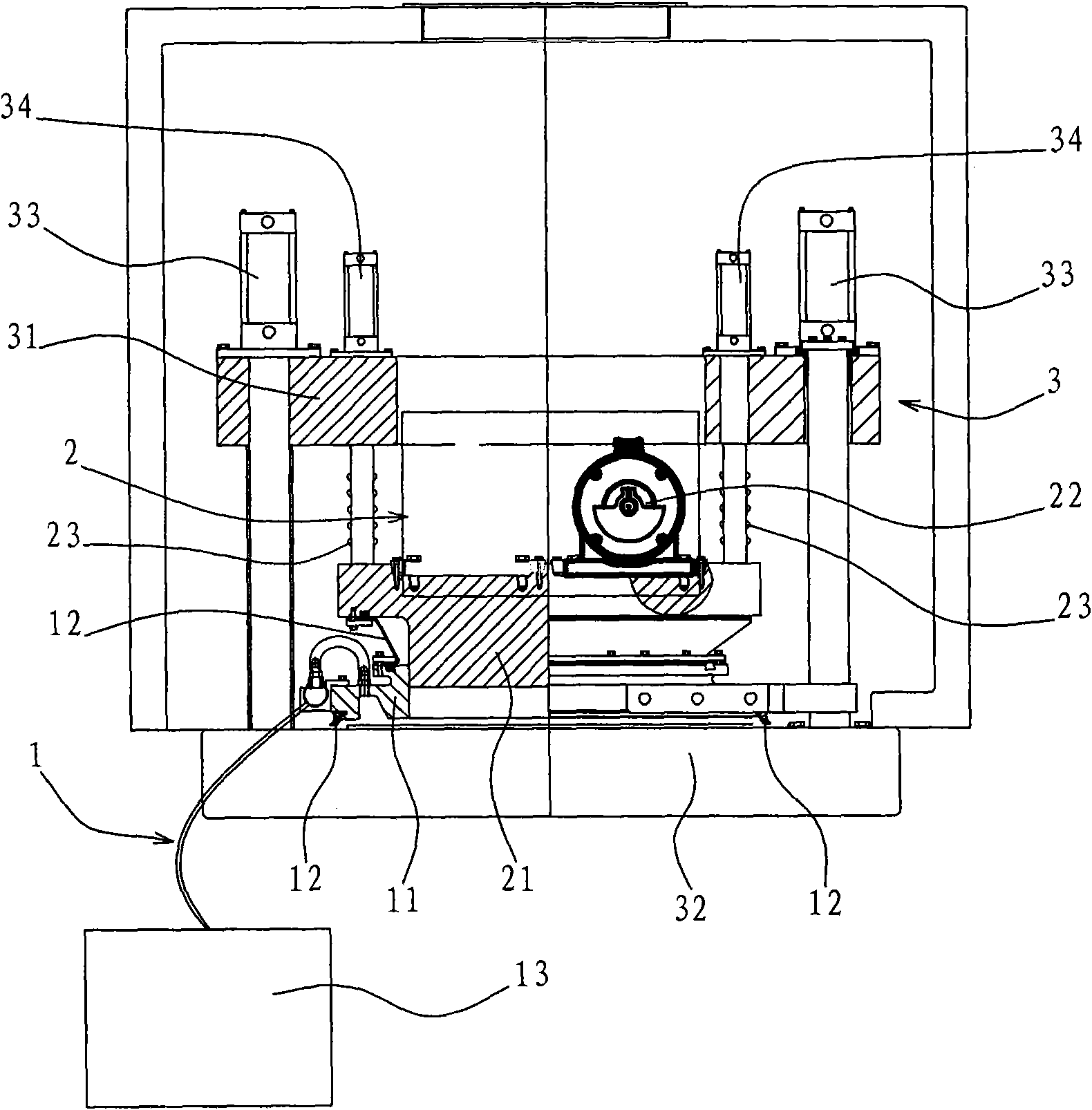

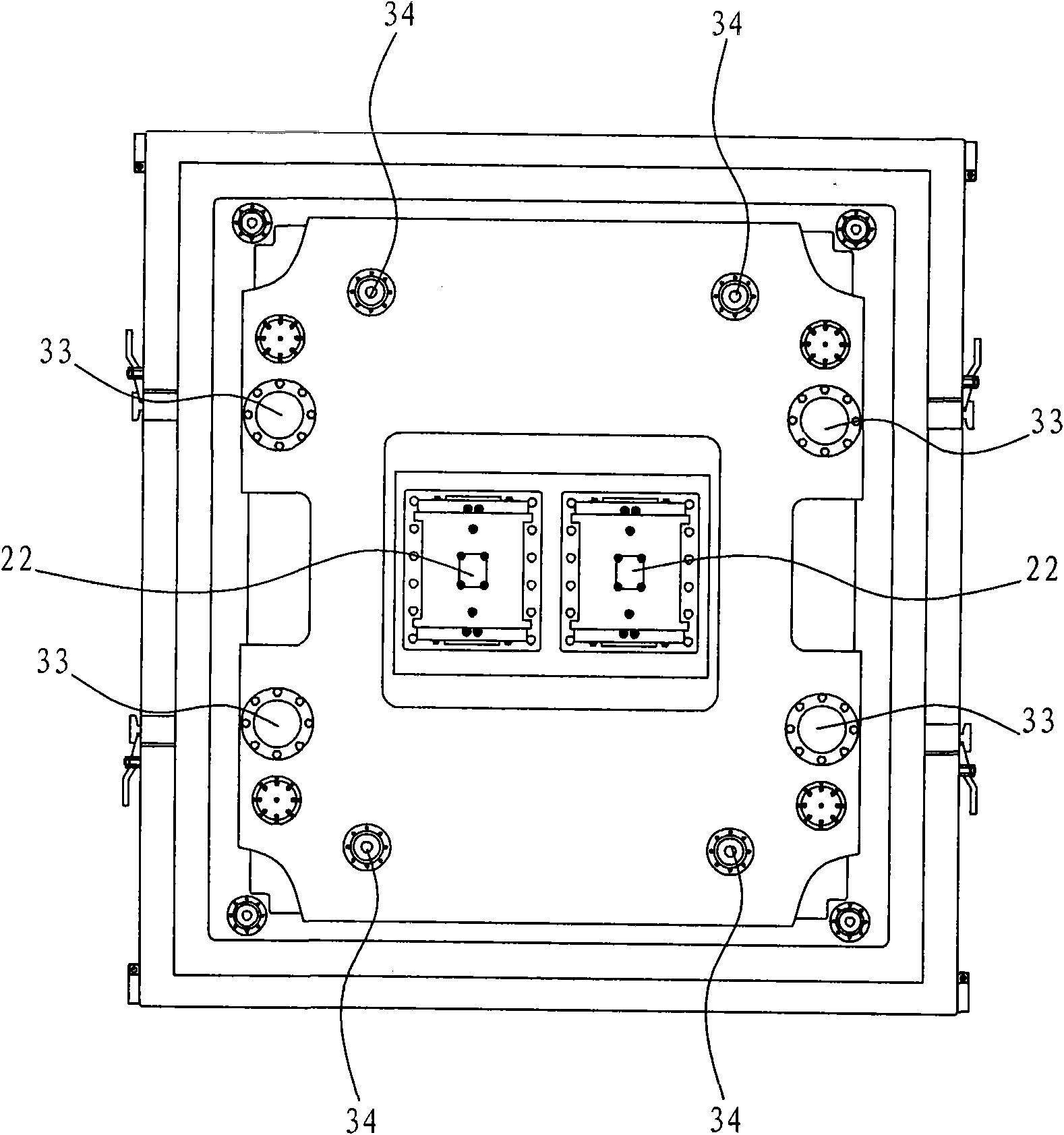

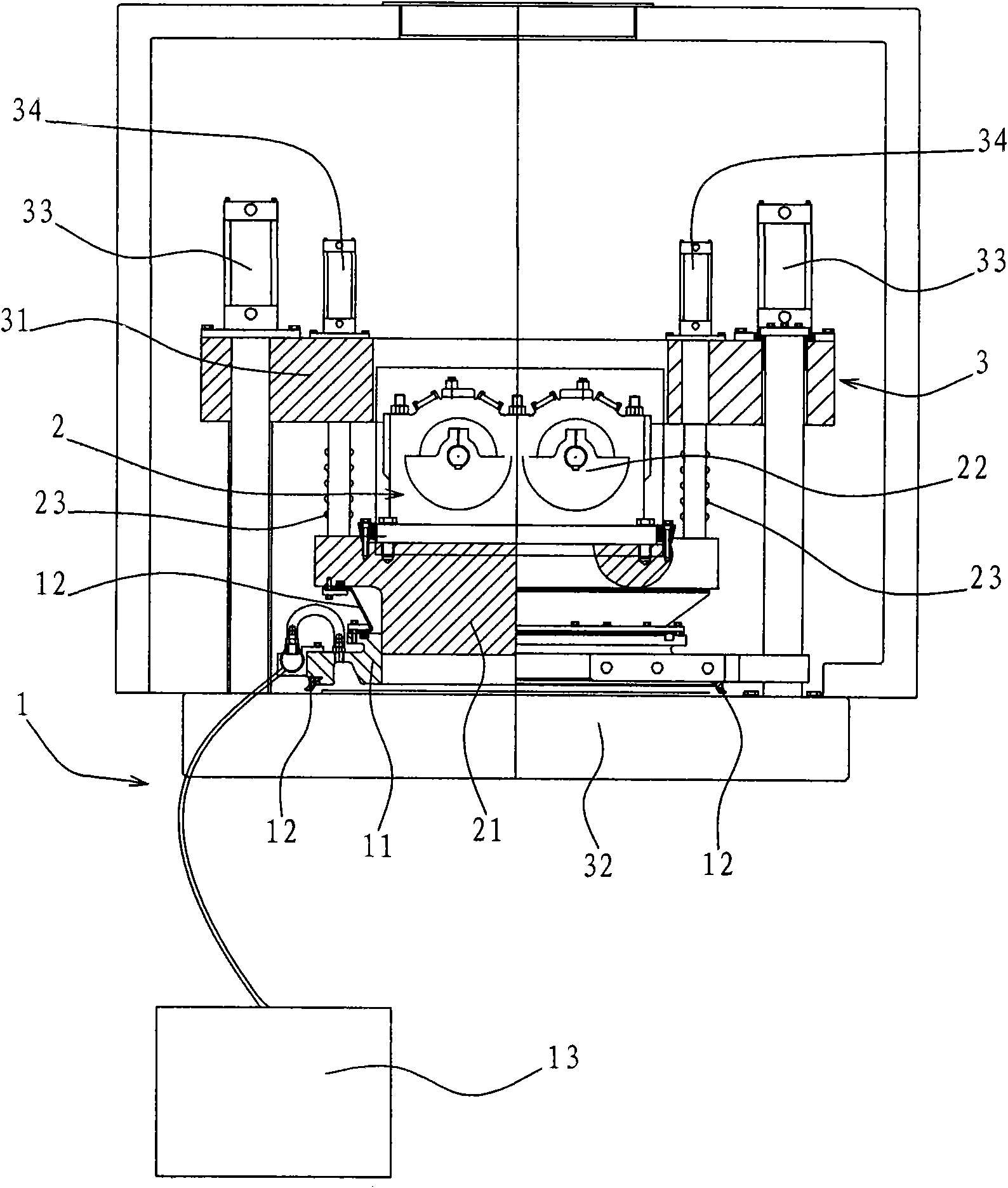

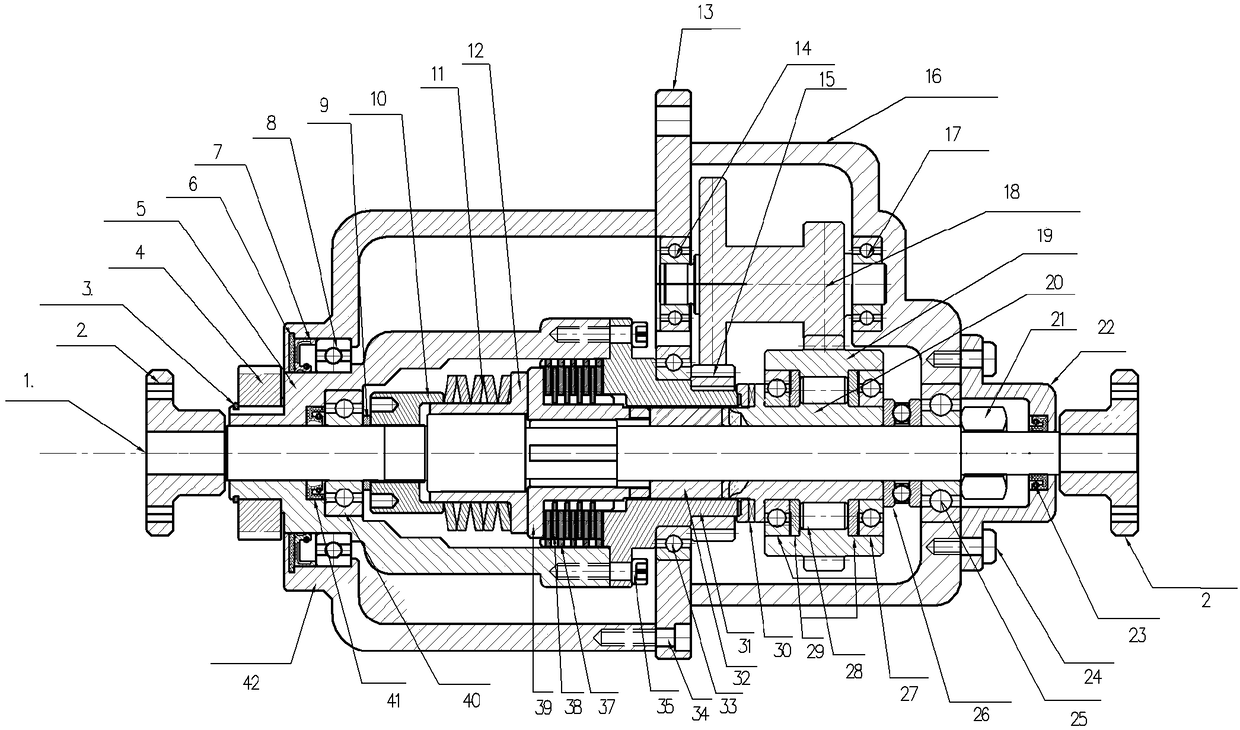

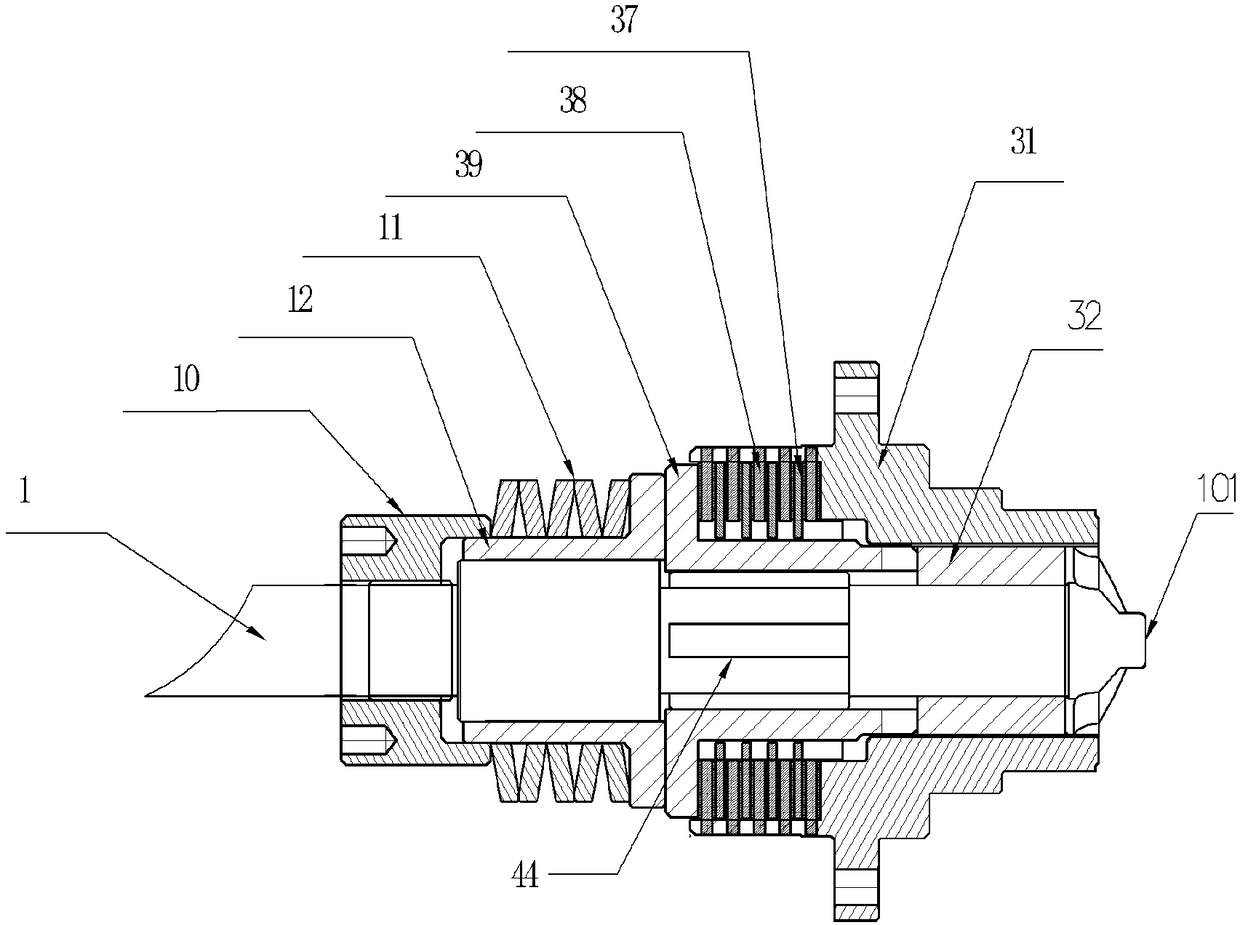

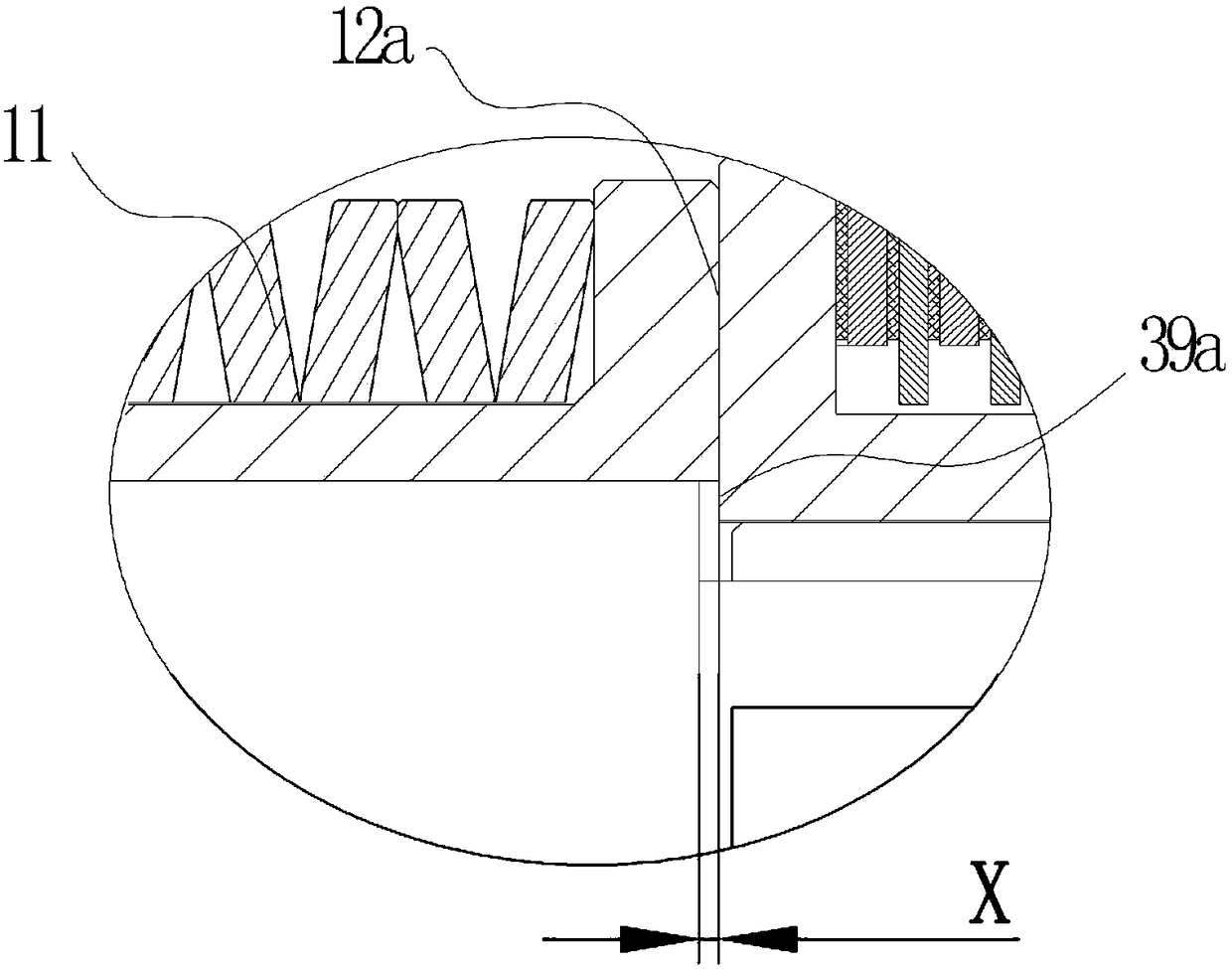

Separate multi-piece type clutch assembly

The invention discloses a separate multi-piece type clutch assembly. The separate multi-piece type clutch assembly is provided with a spline assembly seat and a thrust limiting spiral cam which sleeve a spindle; a plurality of external tooth friction plates and internal tooth lining plates are arranged on the outer side of the spline assembly seat in an alternately overlapped manner; one end of the trust limiting spiral cam is connected with the spline assembly seat while the other end of the thrust limiting spiral cam is provided with a cam; disc springs which press the external tooth friction plates and the internal tooth lining plates on the spline assembly seat are arranged on one side, which is away from the thrust limiting spiral cam, of the spline assembly seat; and a torque adjusting nut is further arranged at the outer end of each disc spring and is used for adjusting the pressing force of the disc spring. The separate multi-piece type clutch assembly has the advantages of simple structure, speedy assembly, easiness in machining, capability of increasing friction area infinitely, good joint surface, high separation speed, zero impact, stable torque force value and the like; axial infinite pressure boosting is limited effectively; and damage of bearings on the spindle is avoided. To sum up, by the separate multi-piece type clutch assembly, axial pressure is reduced, so that switching of driving climbing machines is stable, and sensitivity is relatively high.

Owner:黄山奔马集团有限公司

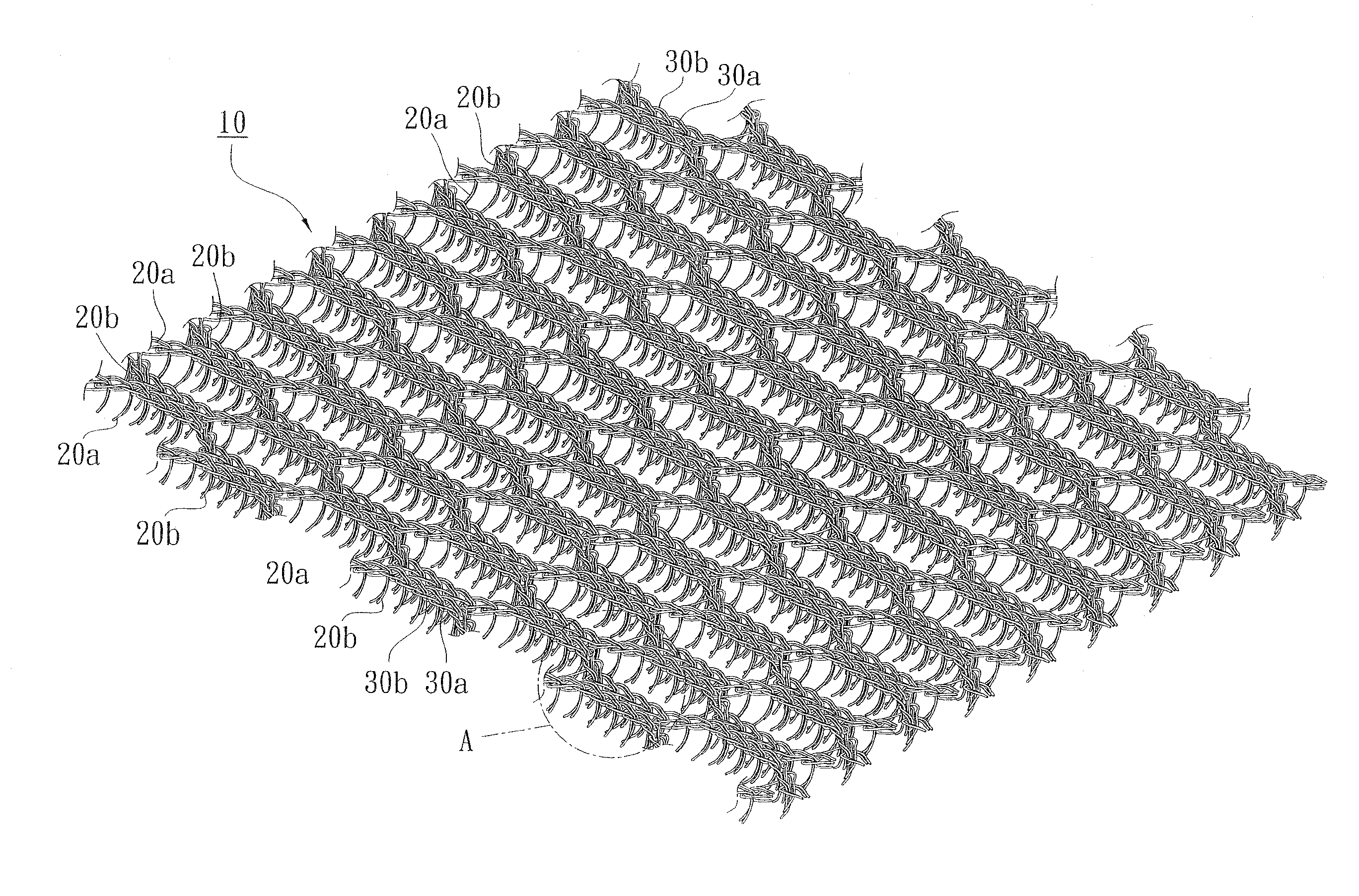

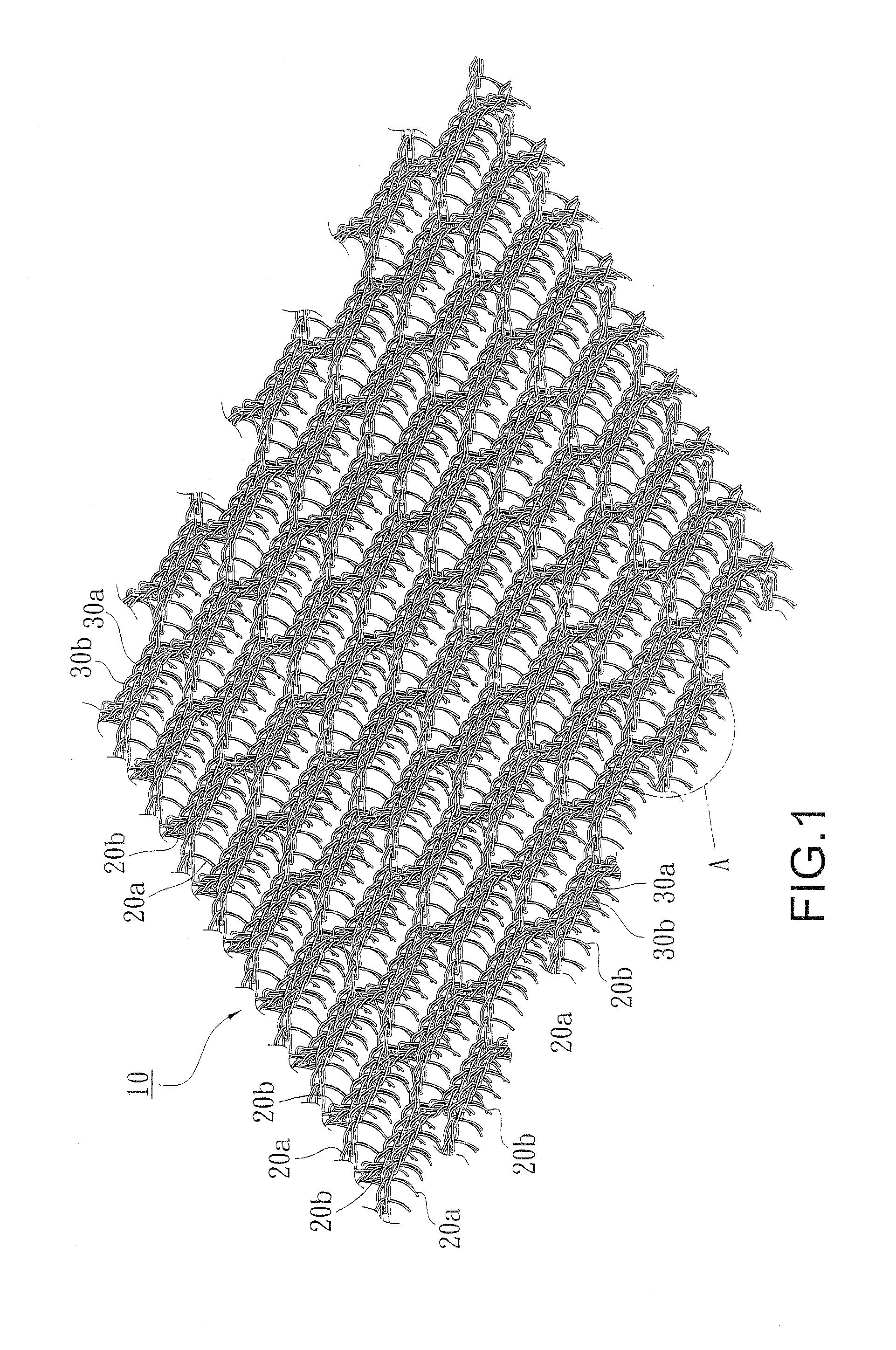

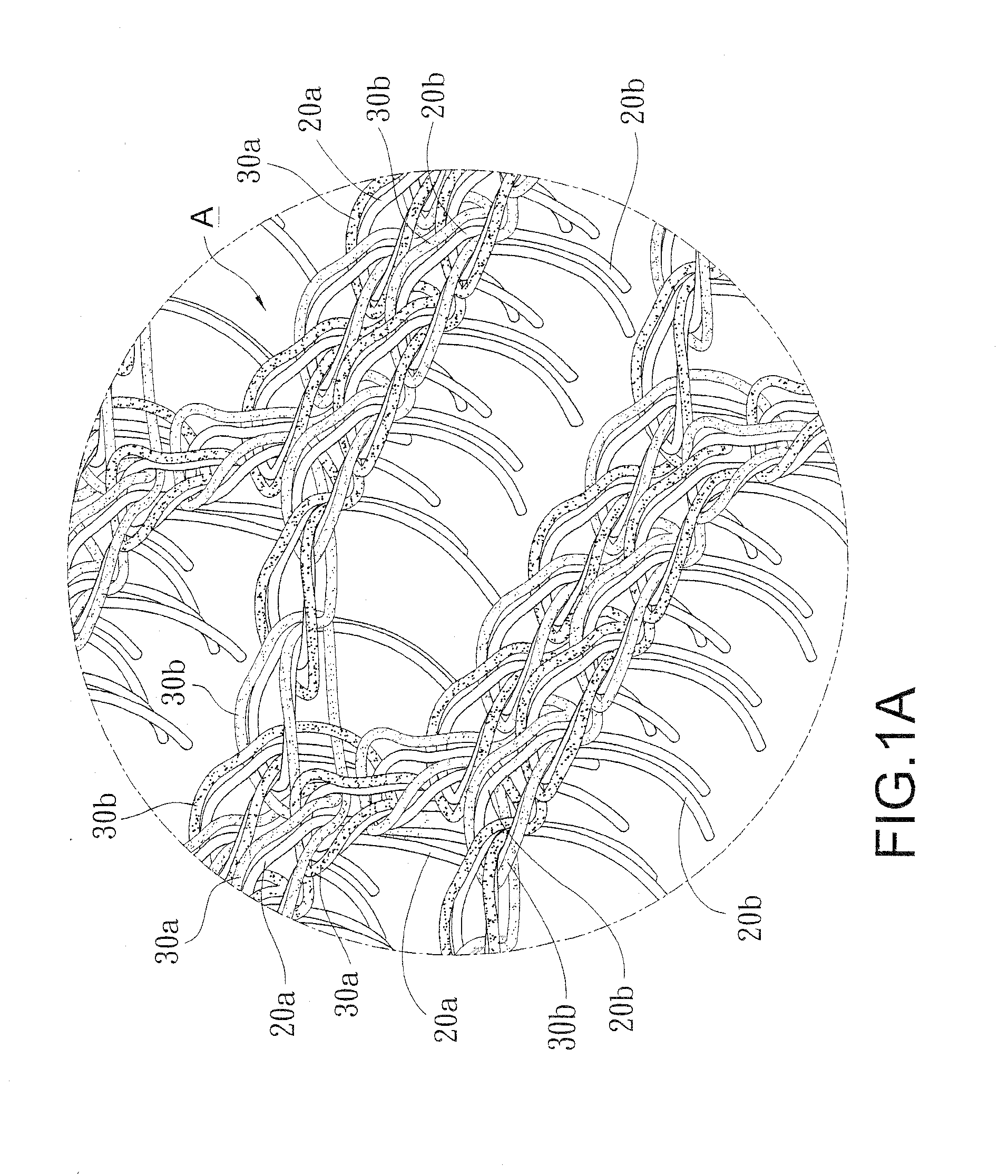

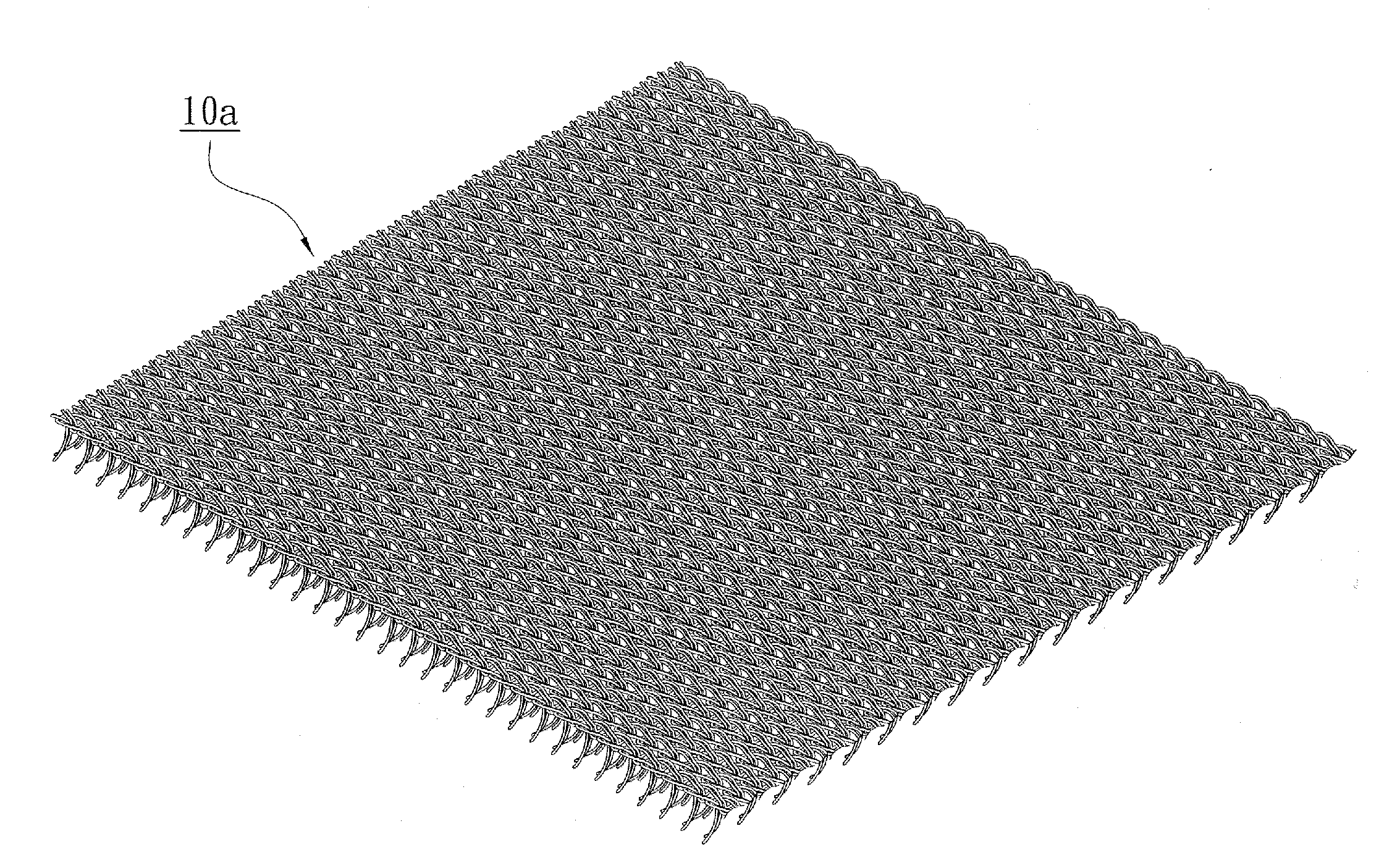

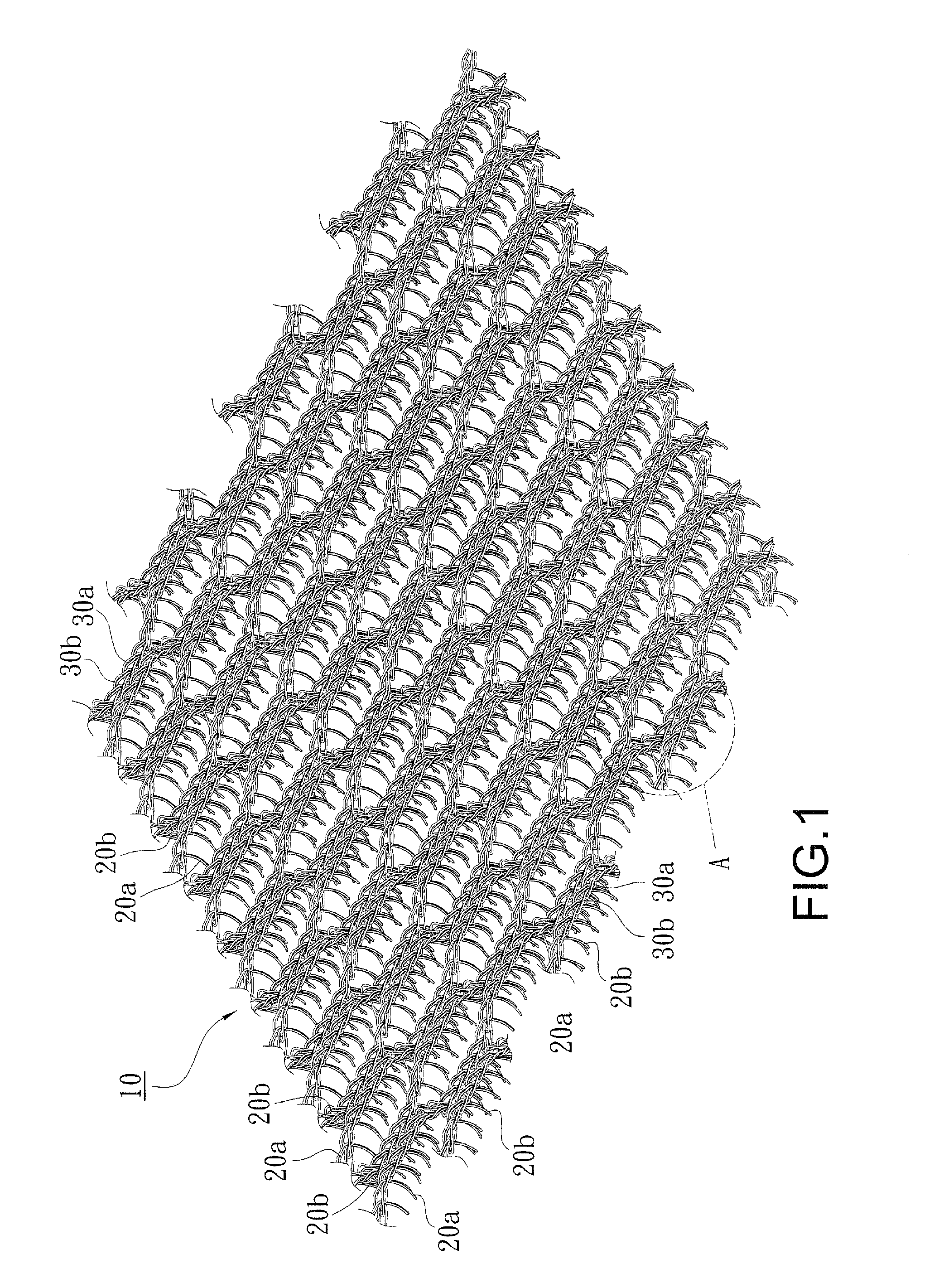

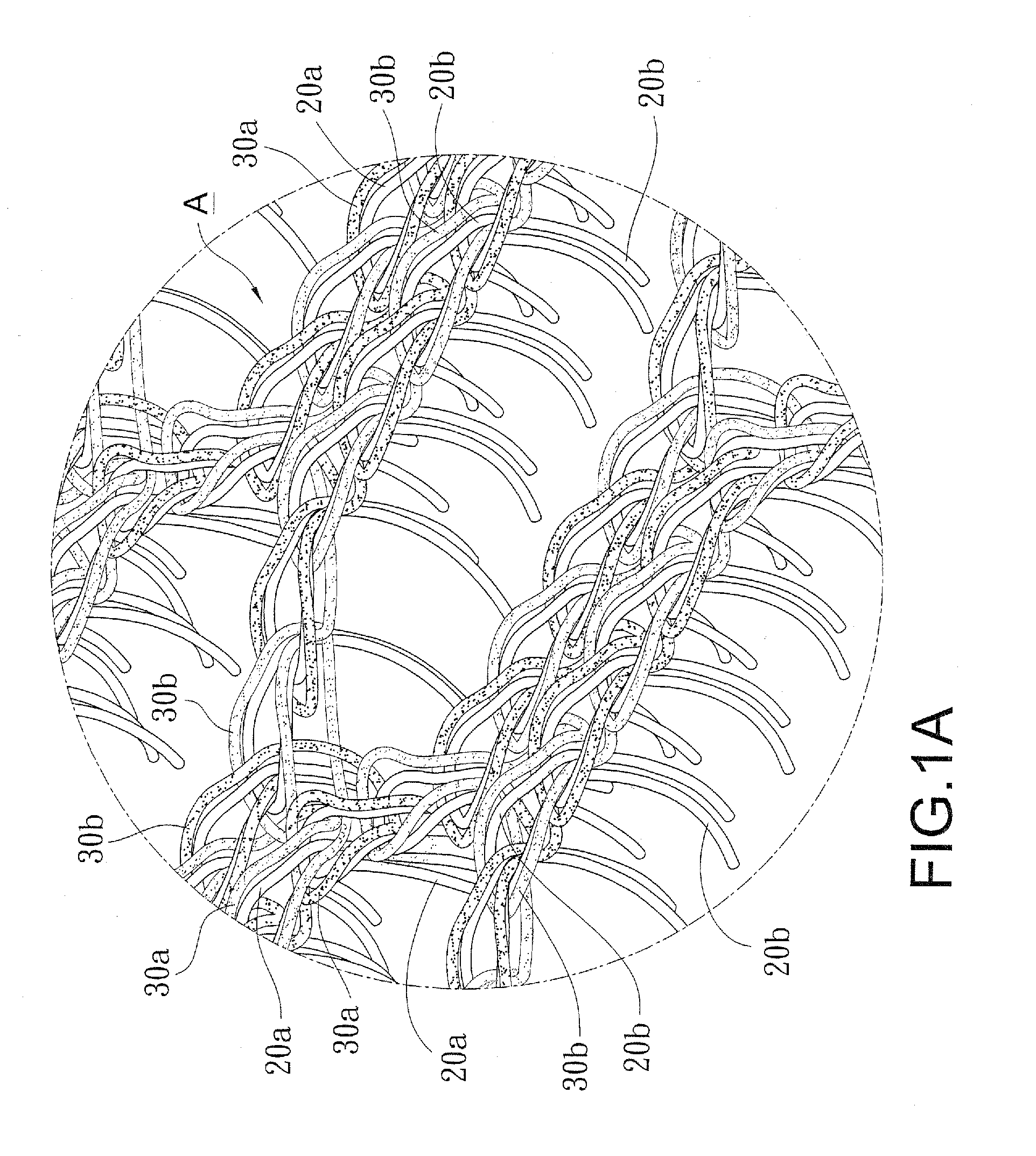

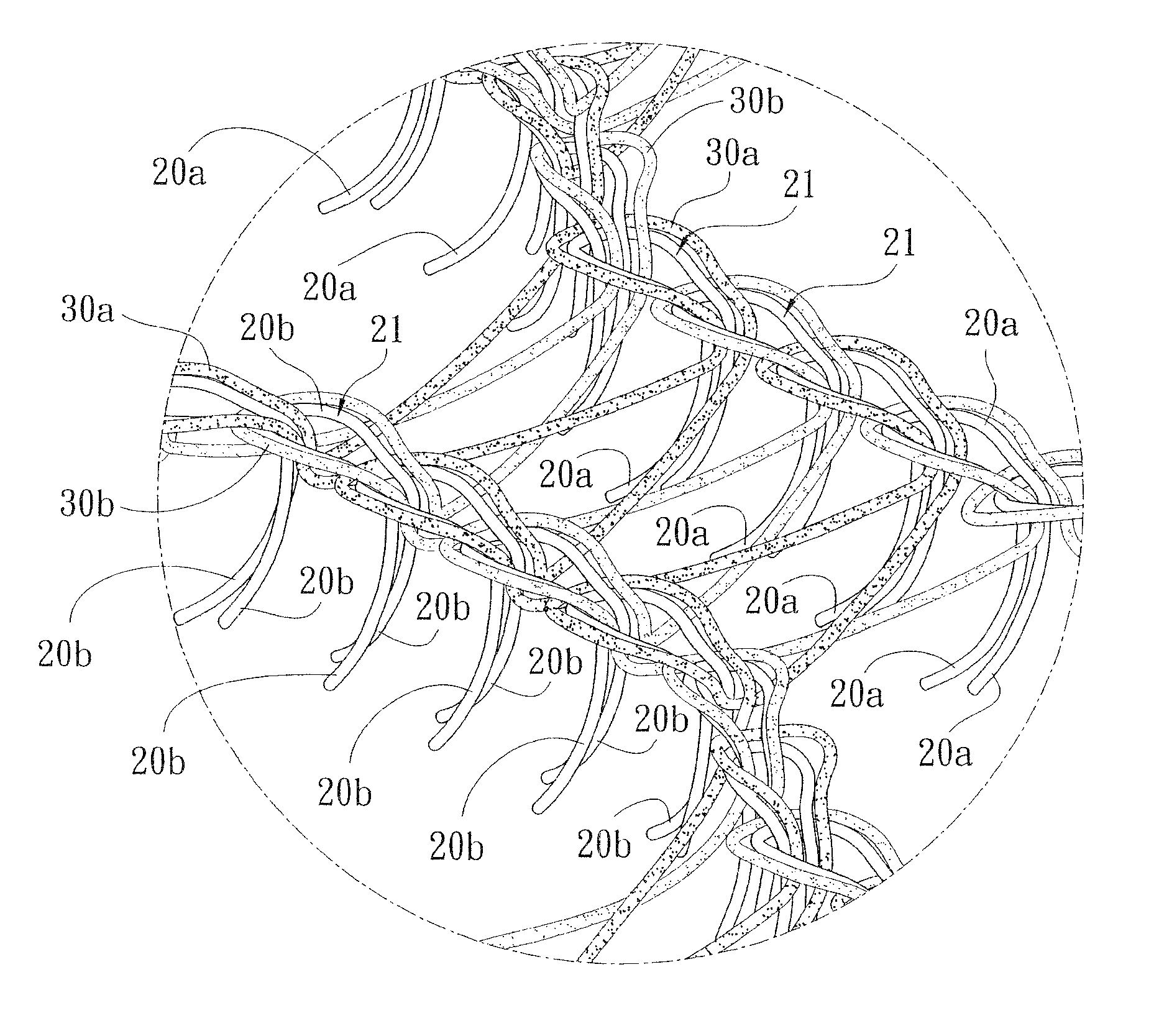

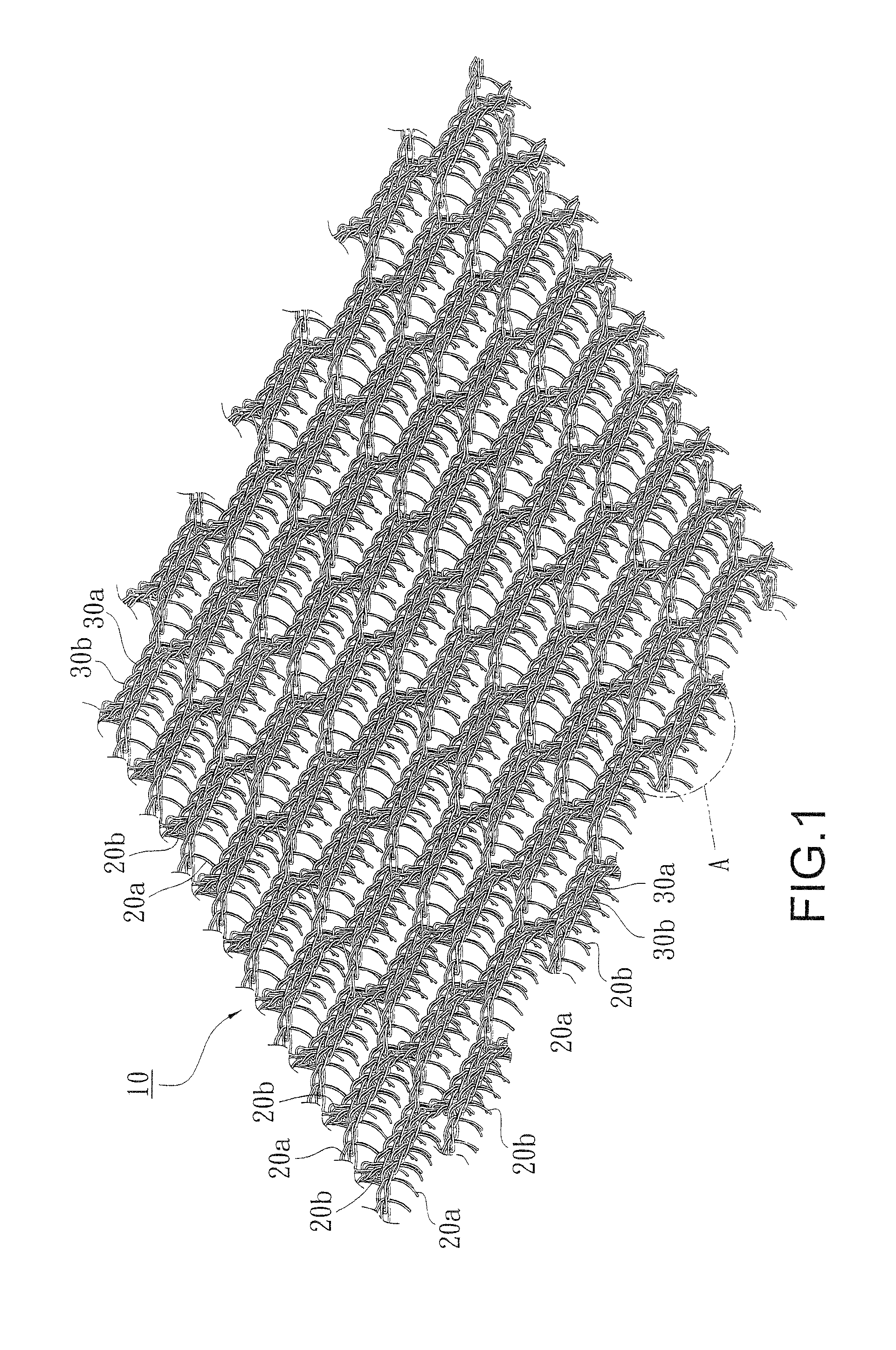

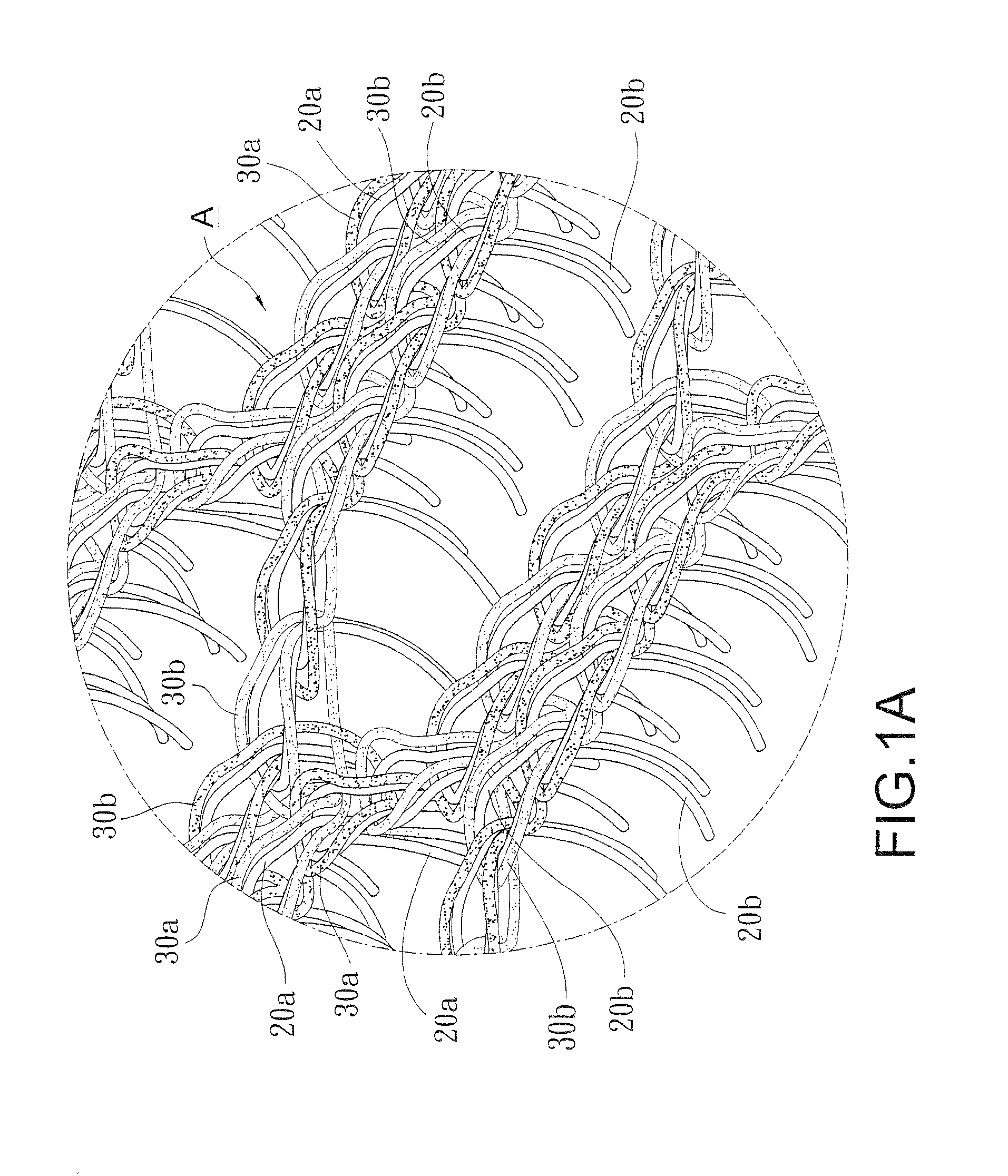

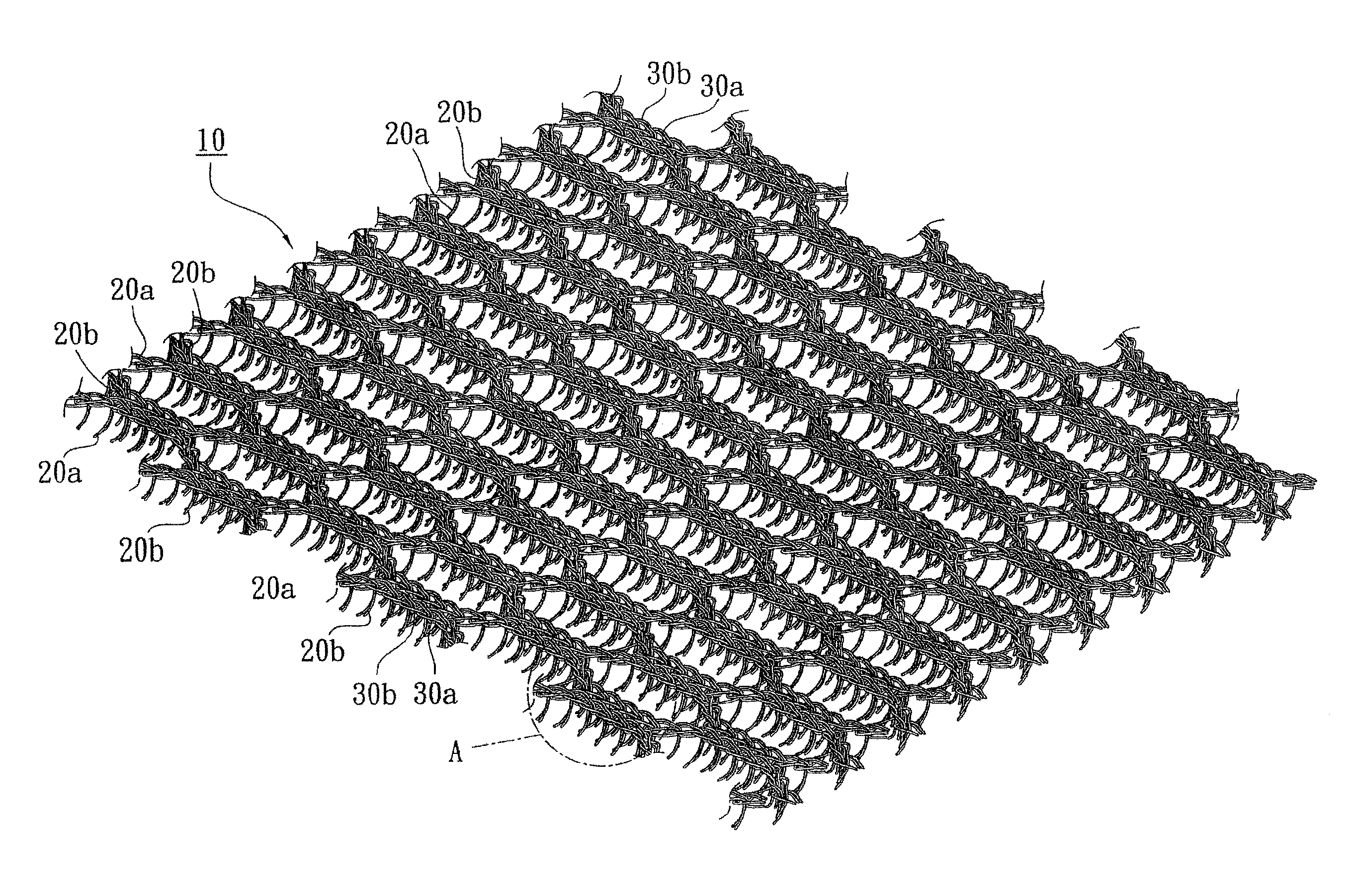

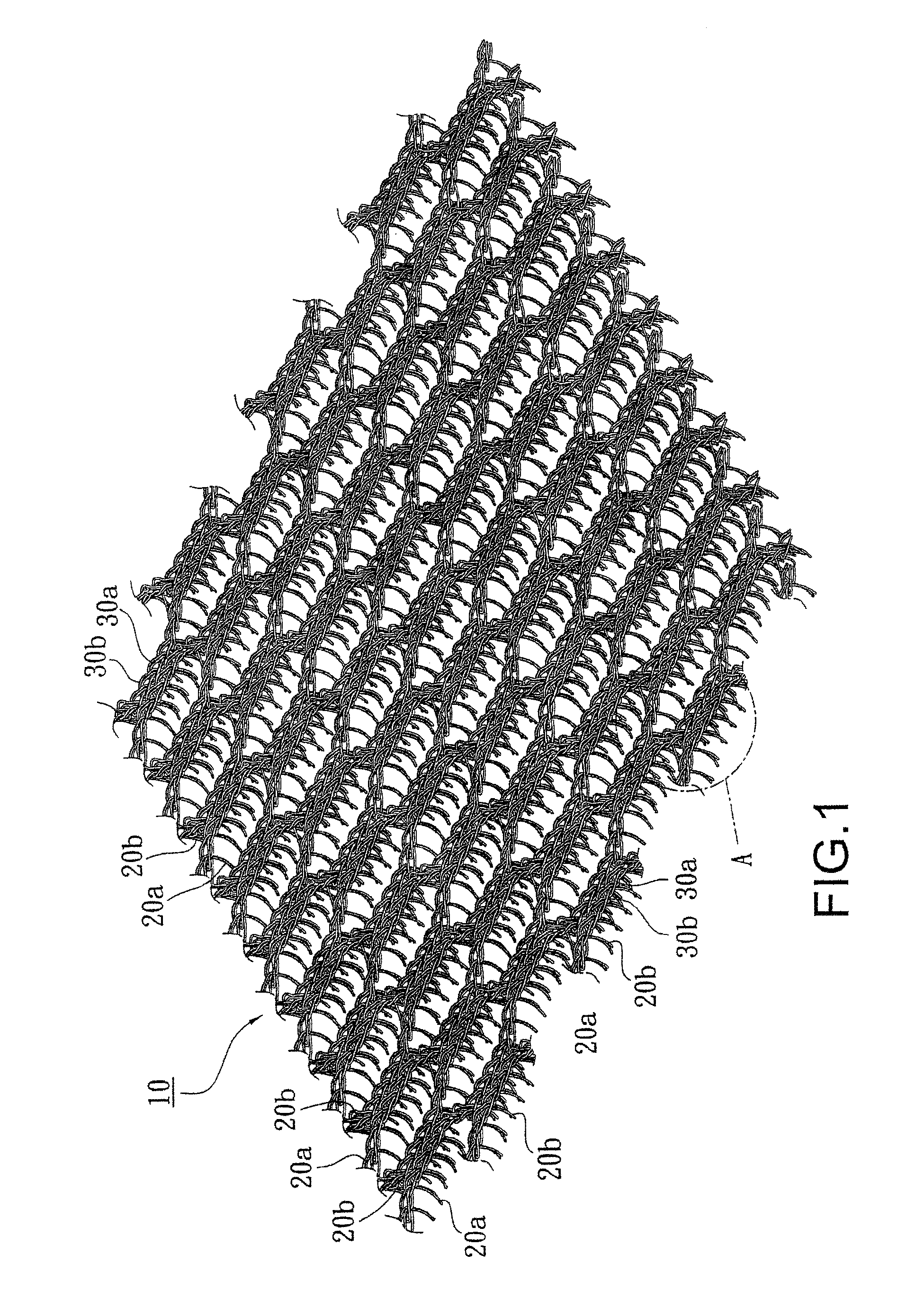

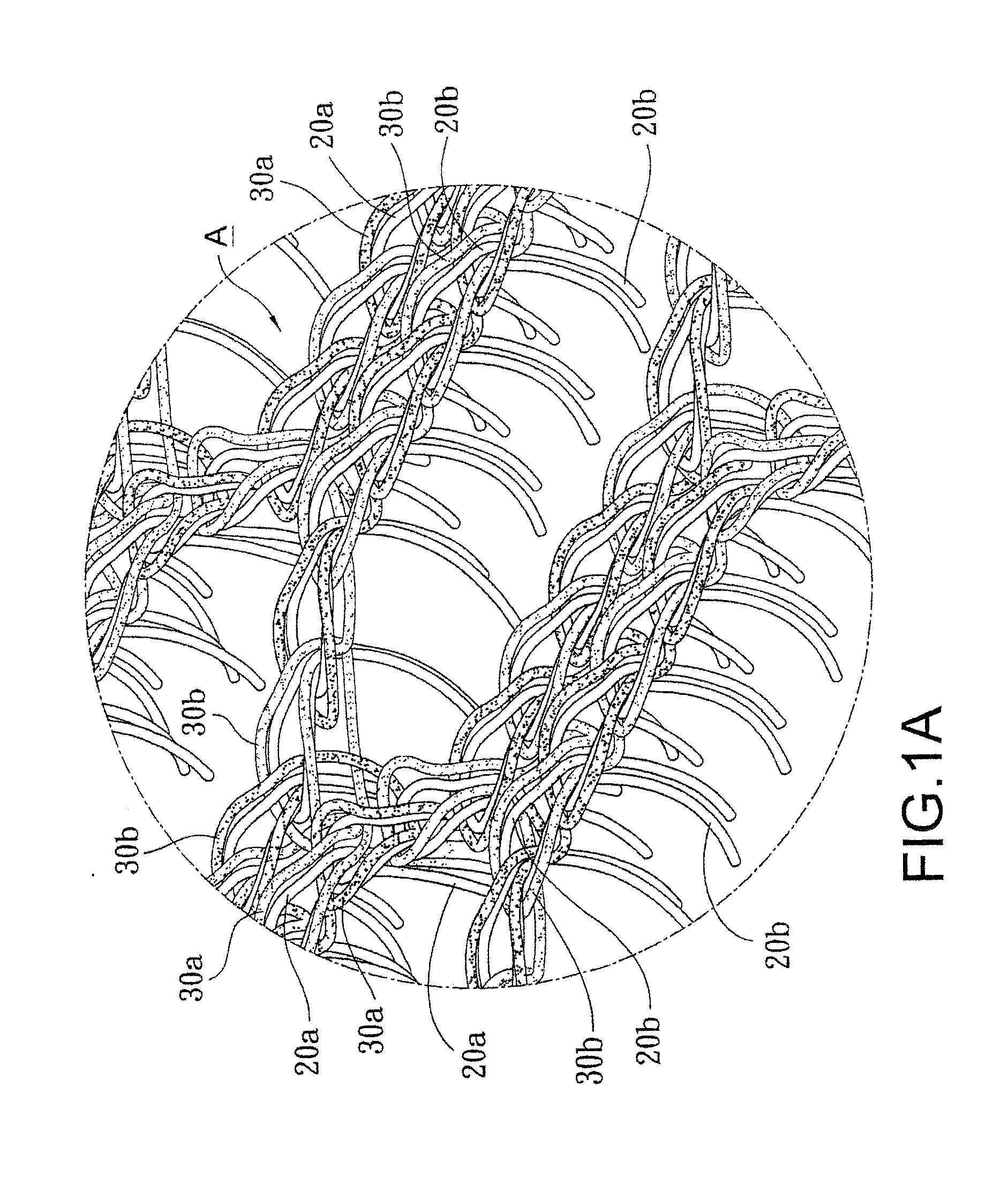

Structure of touch-fastening Anti-skidding material

ActiveUS20110274870A1Excellent resistance against skiddingGood stretchabilityLayered productsWarp knittingYarnEngineering

Owner:FORMOSA SAINT JOSE

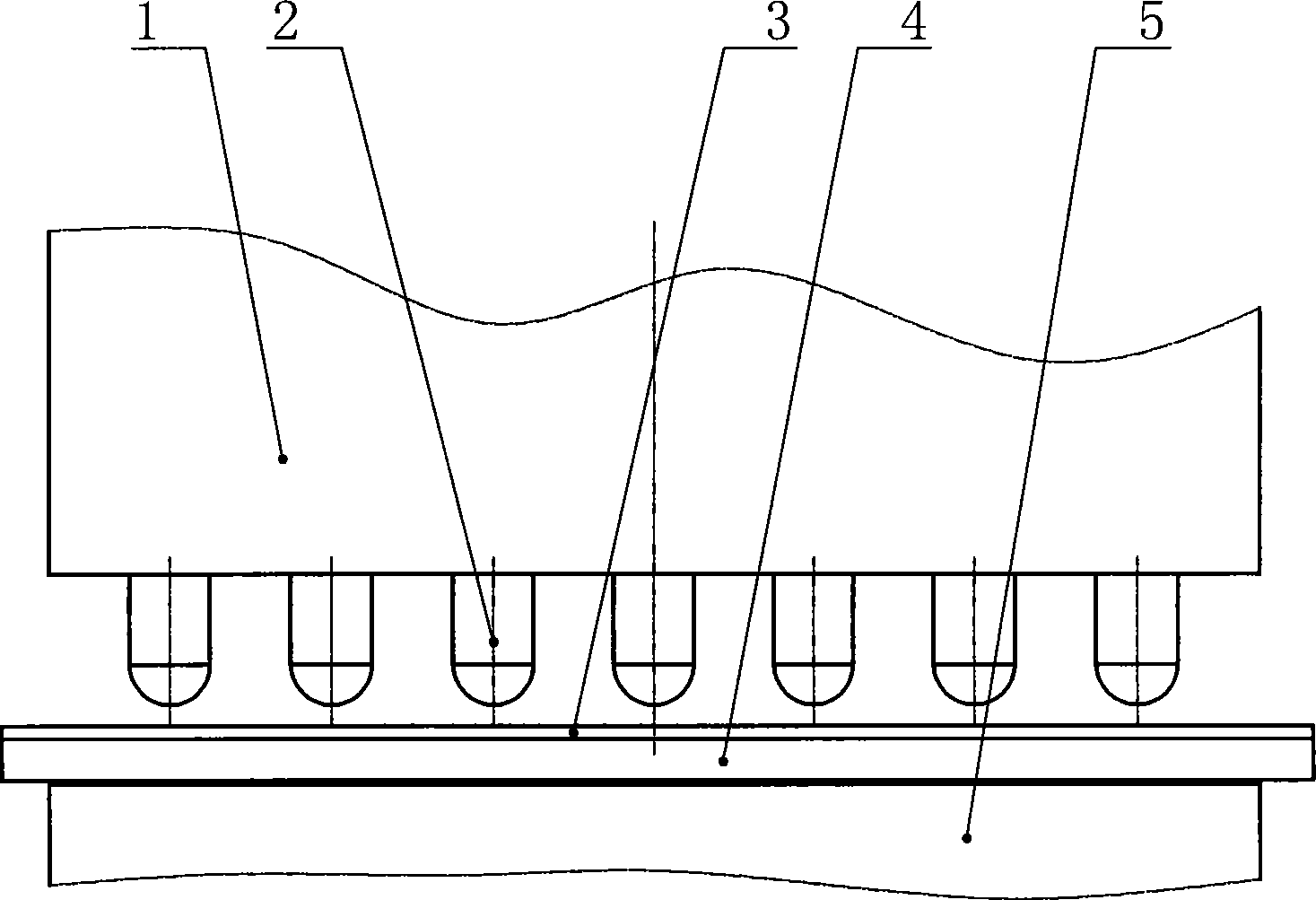

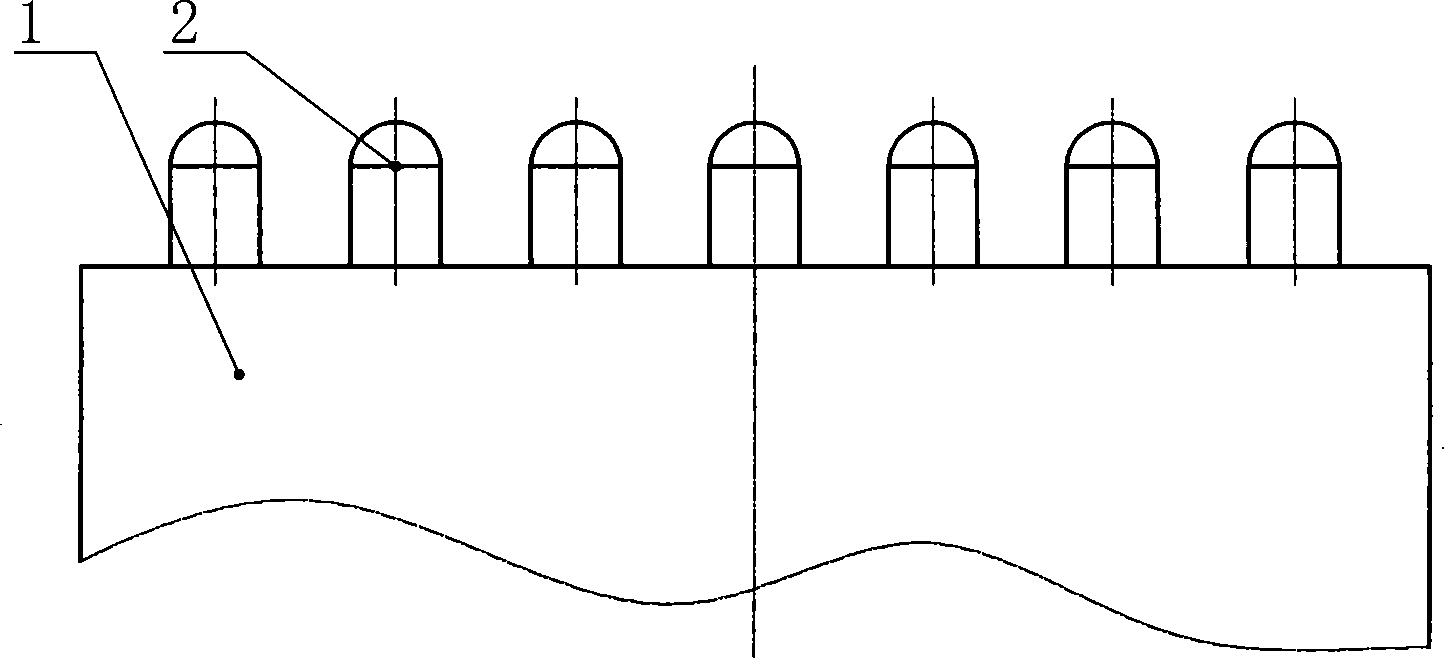

Structure of touch-fastening Anti-skidding material

InactiveUS20110117313A1Excellent resistance against skiddingGood stretchabilityLayered productsWarp knittingYarnEngineering

A touch-fastening anti-skidding material includes a woven foundation layer and a plurality of synthetic yarns that is secured together by being collectively woven in the foundation layer. The foundation layer is formed by dual yarn weaving of pliable base yarns and synthetic yarns. The synthetic yarns are woven in U-shaped loops and the base yarns are woven between adjacent strands of the woven synthetic yarns to make a large area cloth. The cloth may be in a planar form without hollow opening sections or it includes open sections to facilitate air permeability. The loops of the synthetic yarns have legs extending beyond the foundation layer by a predetermined length and the synthetic yarns show rigidity strength, whereby a flexible, resilient, light-weighted, and low-cost touch-fastening anti-skidding material is formed.

Owner:FORMOSA SAINT JOSE

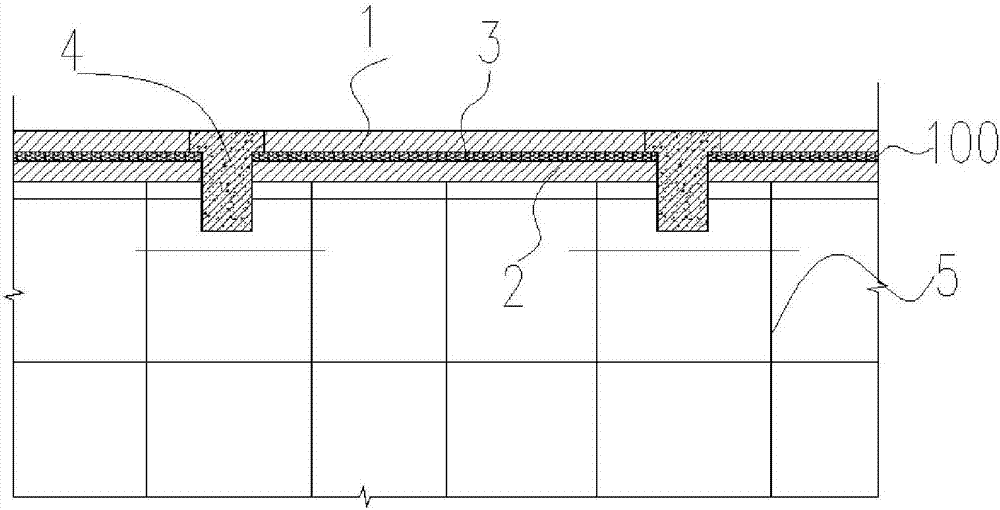

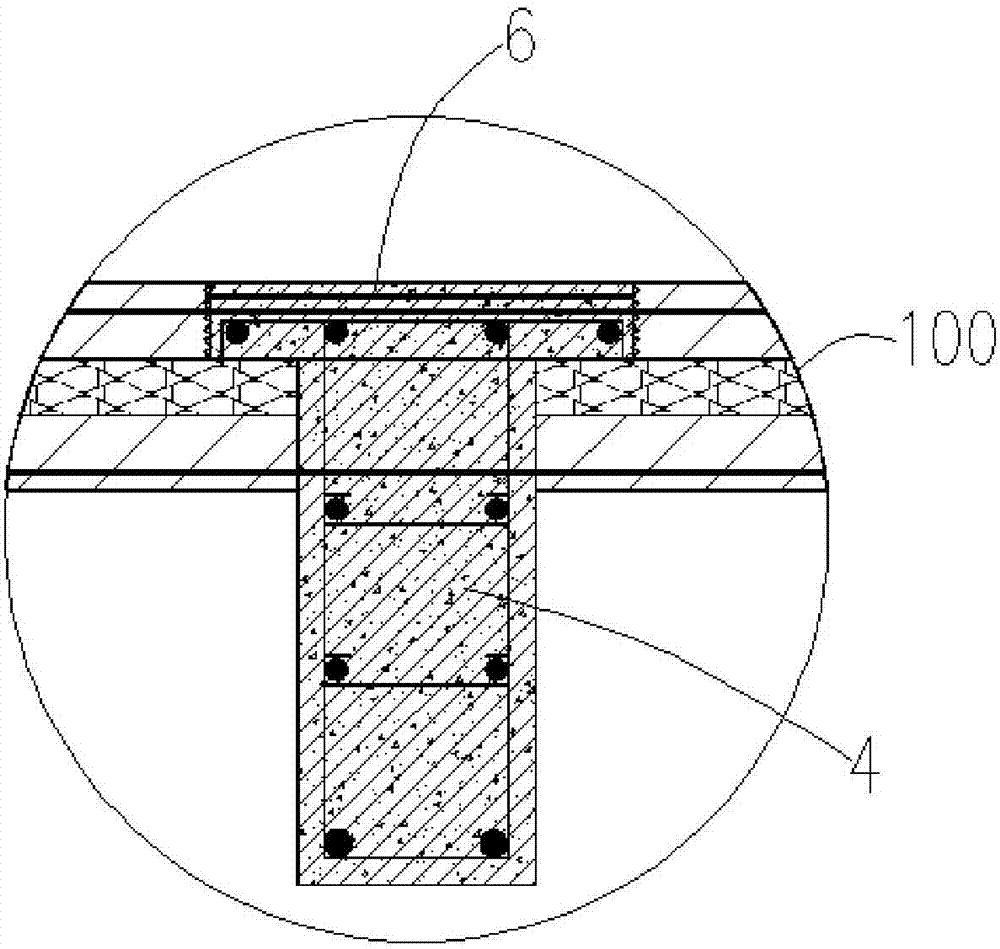

Novel prefabricated heat preservation and sound insulation floor structure and construction method thereof

The invention discloses a novel prefabricated heat preservation and sound insulation floor structure and a construction method thereof. A prefabricated heat preservation and sound insulation floor comprises upper and lower layers of reinforced concrete prefabricated plates and a heat preservation and sound insulation plate. The heat preservation and sound insulation plate is located between the upper and lower layers of reinforced concrete prefabricated plates. The prefabricated heat preservation and sound insulation floor structure is fixedly connected with a cast-in-situ frame beam structure in a cast-in-situ mode to form an integral type frame beam-plate concrete structure. The novel prefabricated heat preservation and sound insulation floor structure can form the integral frame structure with a cast-in-situ frame beam, so that the force bearing requirement is met, and the construction procedures and the construction period are reduced, and meanwhile the heat preservation and sound insulation effects can be also met; and a T-shaped beam member serves as the cast-in-situ frame beam, and a galvanized water stopping steel plate is arranged on the surface of the T-shaped beam member, so that the water seepage prevention property of the junction surface of the prefabricated heat preservation and sound insulation floor and the cast-in-situ frame beam is improved by a large margin.

Owner:JIANGXI THE SECOND CONSTR

Structure of touch-fastening anti-skidding material

ActiveUS8461065B2Good stretchabilityIncrease flexibilityLayered productsWarp knittingYarnEngineering

Owner:FORMOSA SAINT JOSE

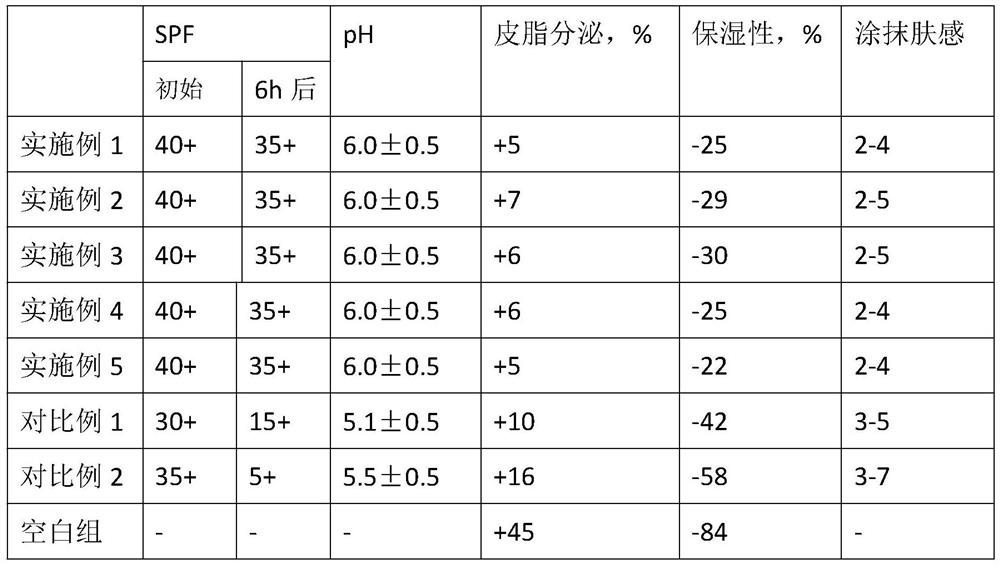

Natural plant-based cool sunscreen composition and preparation method thereof

InactiveCN111888317APromote absorptionRapid heat conduction and heat dissipationCosmetic preparationsSilicaSkin permeabilityNano zinc oxide

The invention provides a natural plant-based cool sunscreen composition and a preparation method thereof. The sunscreen composition is composed of a plant extract matrix and effective sunscreen components, wherein the mass ratio of the effective sunscreen components to the plant extract matrix is 1: 20-25; the plant extract matrix comprises an aloe-phellodendron extract, a hollow carrier, seaweedgel and refined water; the effective sunscreen components comprise nano-zinc oxide, nano-titanium dioxide and nano-boron nitride. The inorganic sunscreen components are uniformly dispersed and loadedon the hollow carrier by reasonably optimizing matching of the raw material, and meanwhile, the outer layer is coated with the breathable maintenance layer, so that the sunscreen composition is cool,refreshing, moist, quick in heat conduction and heat dissipation, beneficial to improvement of skin permeability absorbability and quick moisturizing, and good in comprehensive ultraviolet shielding performance, and can achieve efficient protection.

Owner:南京宜薇安化妆品科技有限公司

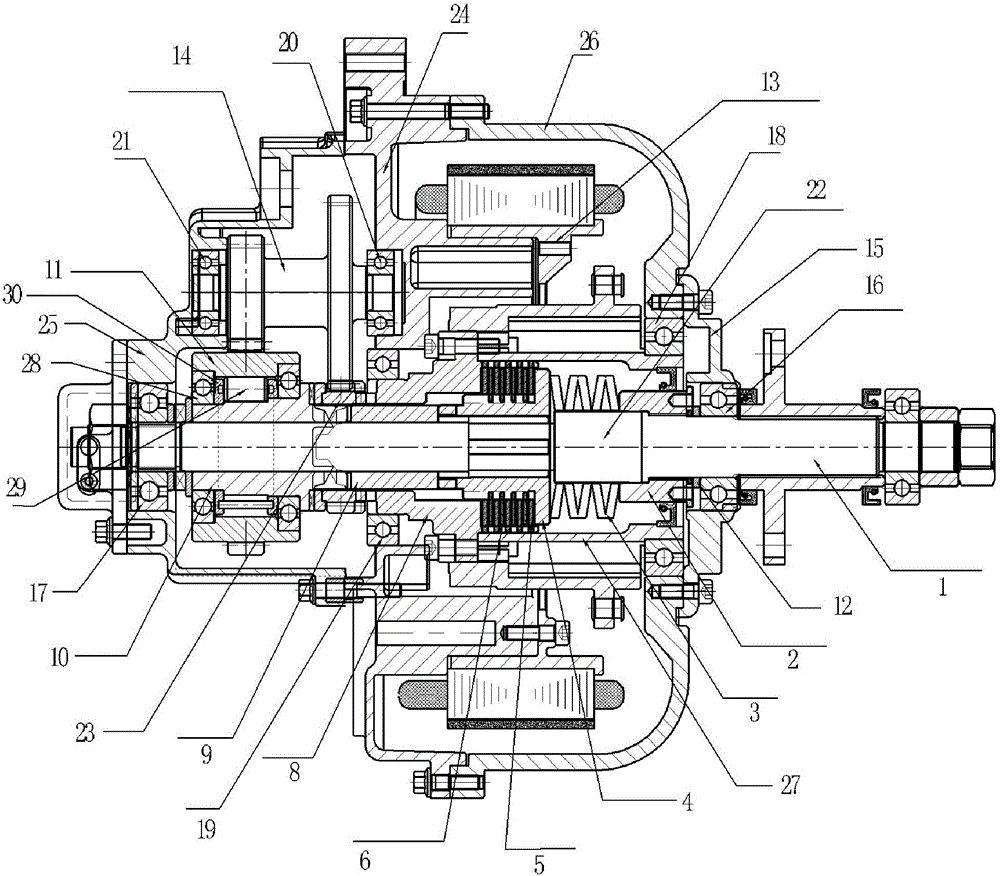

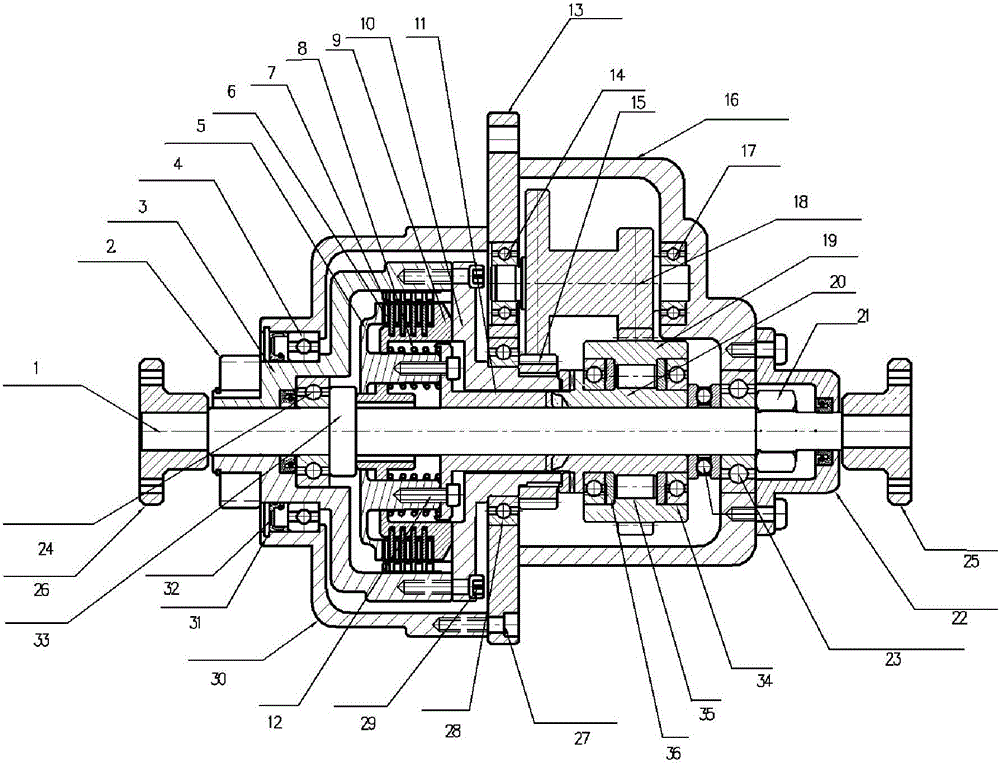

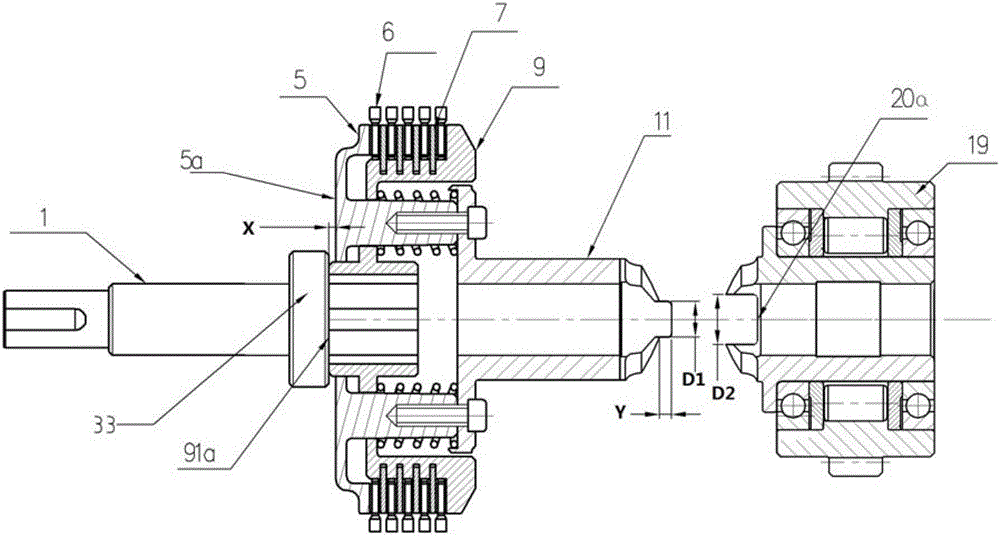

Friction plate type self-adapting automatic separation driving assembly of inner rotor motor of electric motor cycle

ActiveCN105947102ASimple structureQuick assemblyFriction clutchesVehicle transmissionGear wheelAxial pressure

The invention discloses a friction plate type self-adapting automatic separation driving assembly of an inner rotor motor of an electric motor cycle. The friction plate type self-adapting automatic separation driving assembly comprises a driving motor, a tank body, and a main shaft which is matched with the tank body in a rotating manner and outputs power, and further comprises a gear base, a clutch assembly, a first-stage gear, a transmission unit, a one-way gear and a one-way limiting screw cam. According to the friction plate type self-adapting automatic separation driving assembly disclosed by the invention, a novel plane type clutch assembly is used for transmitting torque, so that the friction plate type self-adapting automatic separation driving assembly has the advantages of being simple in structure, fast and convenient to assemble, easy to process, good in joint surface, fast in separation, free from impact, stable in torque force value, and the friction area can be infinitely increased. Through adjusting the number of external tooth friction pieces and the number of inner tooth liners and / or adjusting torque, nuts are adjusted to meet different requirements for the torque; when the torque is greater than a calibration value of the clutch assembly, the one-way limiting screw cam drives a thrust limiting screw cam, so that the external tooth friction pieces and the inner tooth liners are mutually loosened, the situation that the pressure in an axial direction is infinitely increased is effectively limited, the situation that the axial pressure of the main shaft is lower than 5000N is guaranteed, and the damage of a bearing on the main shaft is avoided.

Owner:黄山奔马集团有限公司

Structure of touch-fastening Anti-skidding material

InactiveUS20130269395A1Excellent resistance against skiddingGood stretchabilityWarp knittingStraight-bar knitting machinesYarnEngineering

Owner:FORMOSA SAINT JOSE

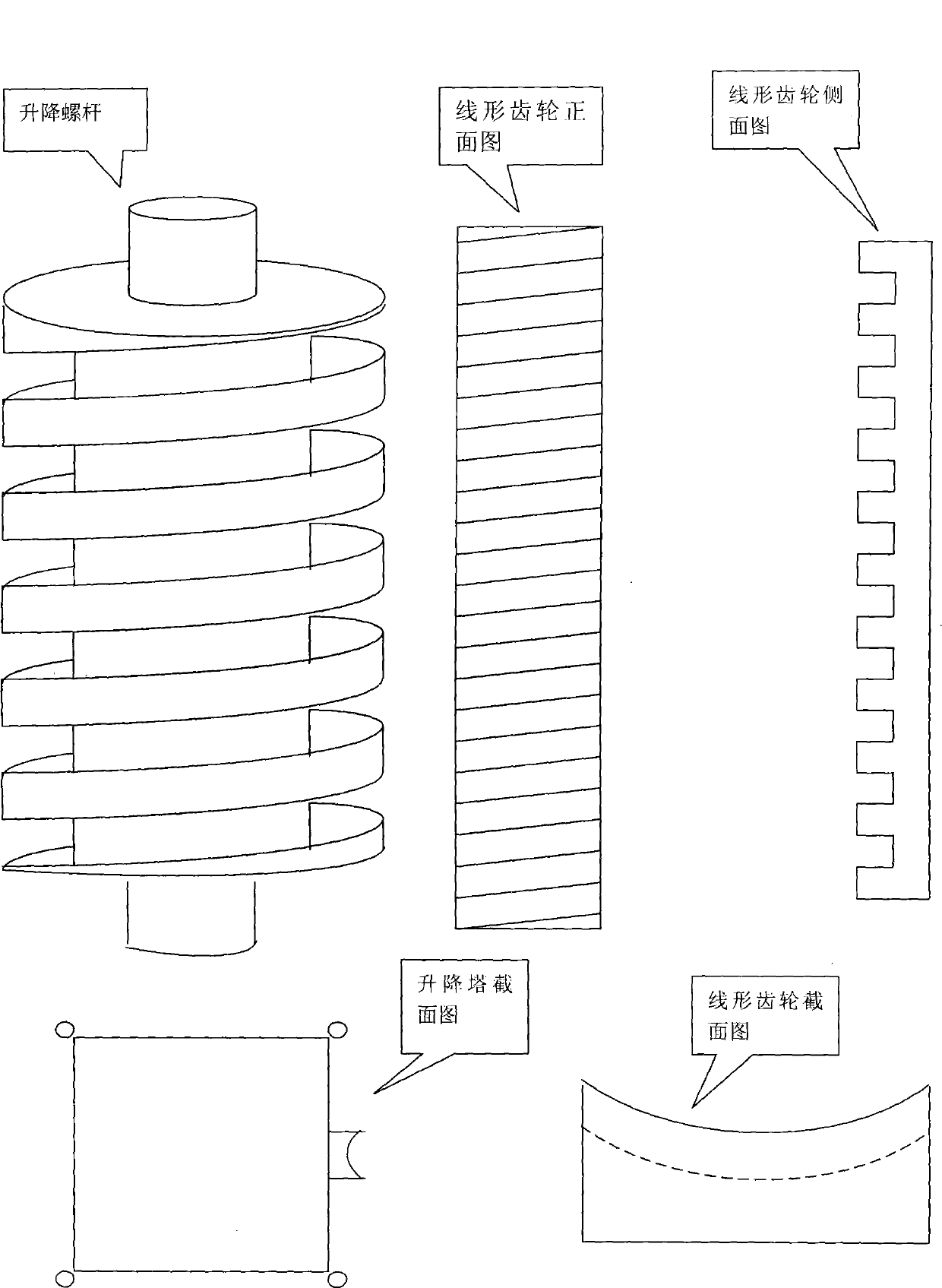

Lifting device for construction elevator

InactiveCN102079472ASimple structureGood for running up and downElevatorsBuilding liftsGear wheelArchitectural engineering

The invention relates to a lifting device for a construction elevator. The conventional construction elevators in the market are in a gear rack type mostly, the lifting work is completed by moving a gear on a rack, and defects of large noise, high possibility of being worn and the like exist. The lifting work is completed by rotating a screw rod on the rack, and the lifting device has the advantages of safety, low possibility of dropping and being worn, small noise and the like.

Owner:洪朝彬

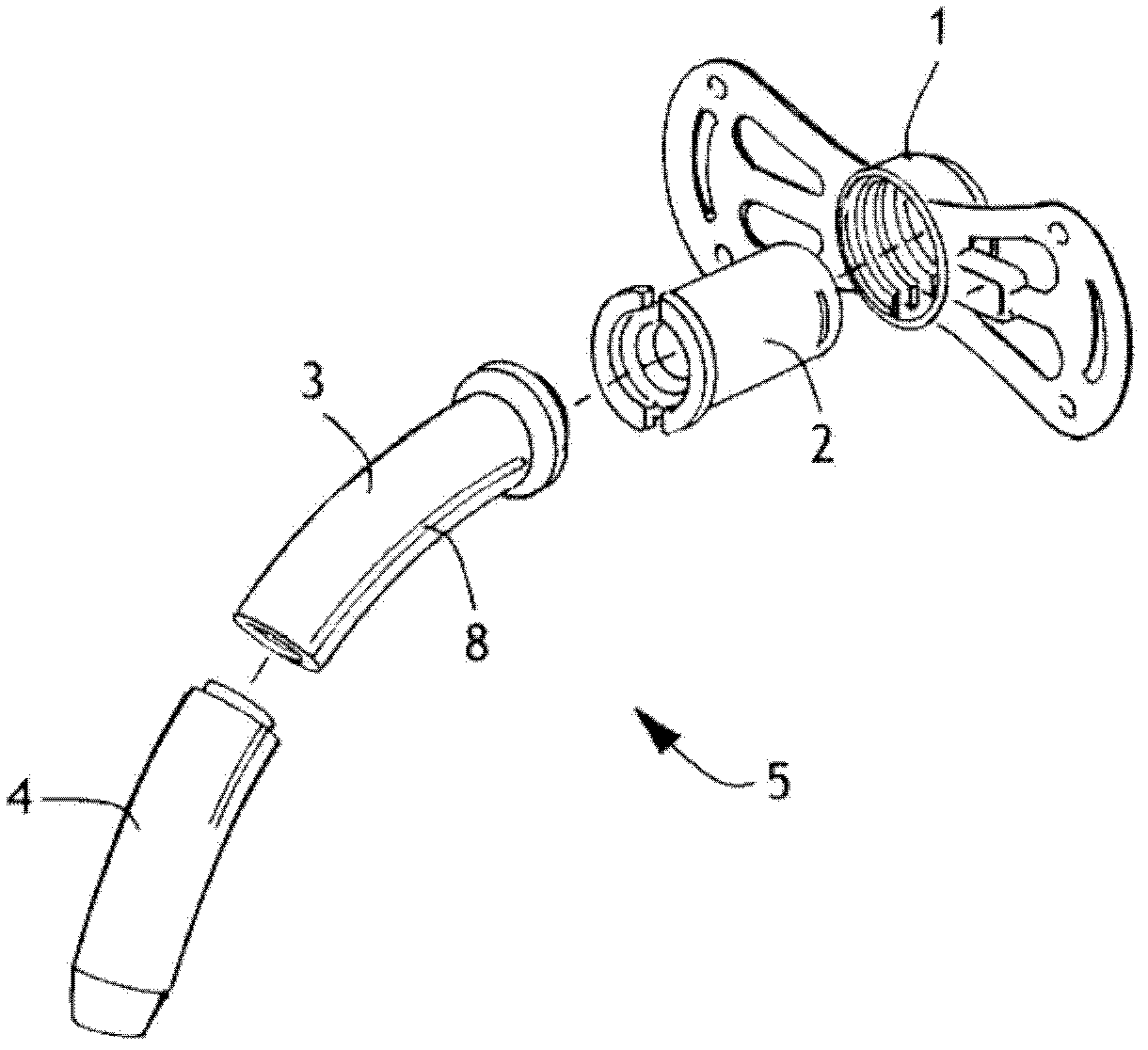

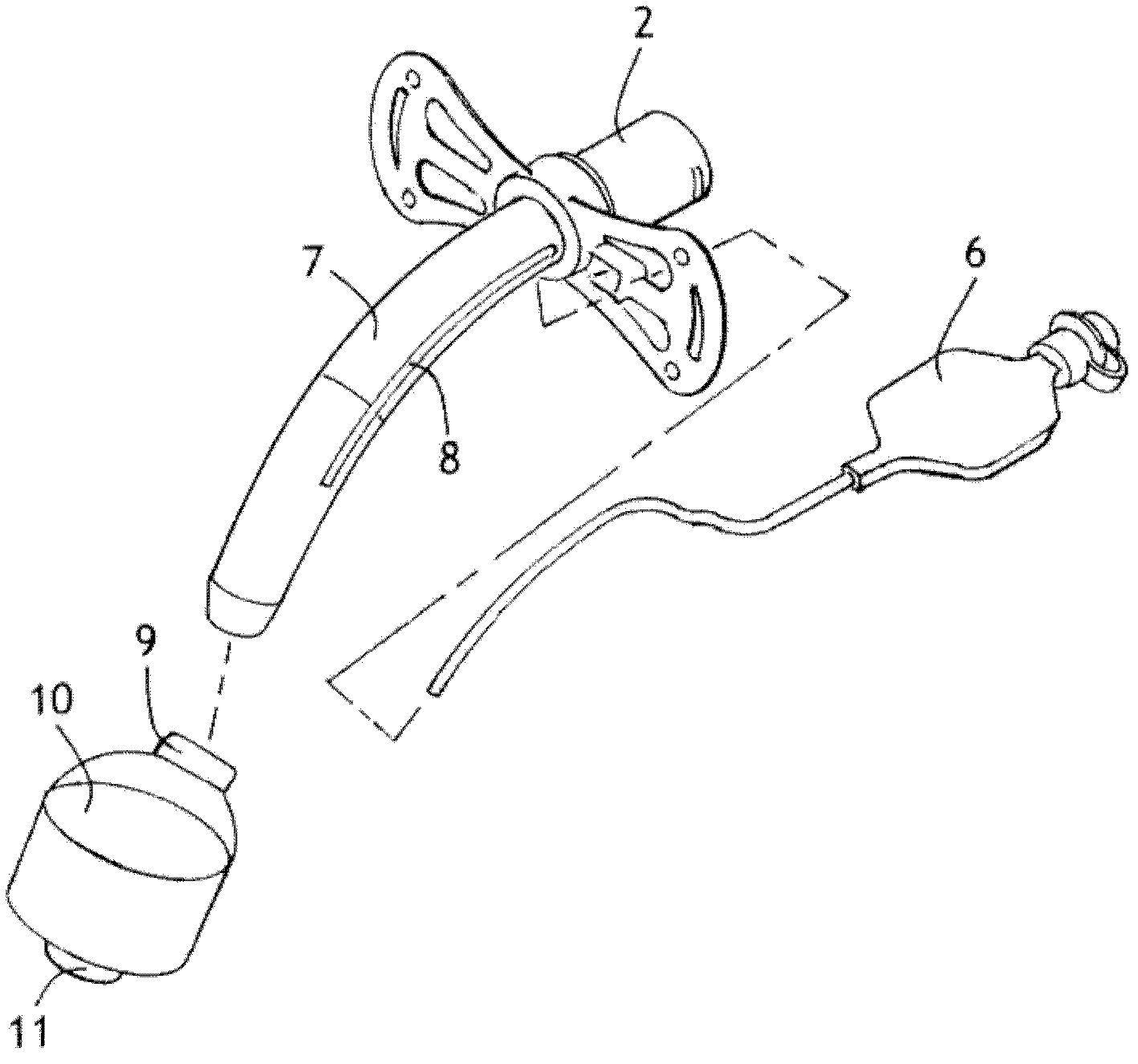

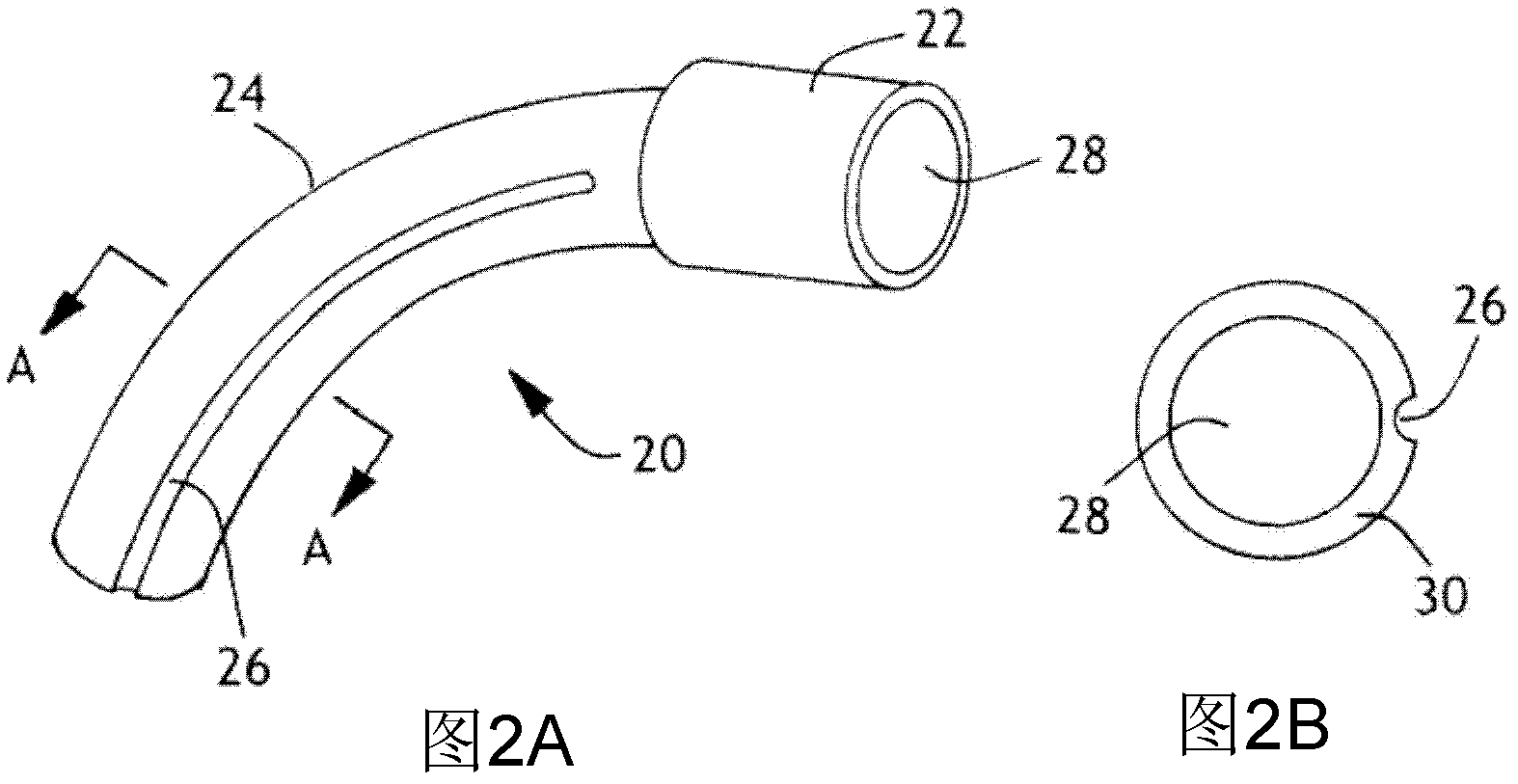

Tracheostomy tube

InactiveCN102438687AOvercome breakageLow flexibilityTracheal tubesMedical devicesTracheal tubeTracheal wall

There is provided an improved tracheostomy tube (40) having a distal section (34) that over-molds a proximal section (24). The distal section is desirably made from a more flexible polymer than the proximal section to reduce trauma should the distal section contact the tracheal wall. The insertion of the tracheal tube in the trachea results in large forces being exerted on the tube. Forces acting on the tube after installation can also be rather large. Over-molding of the proximal section by the distal section results in a stronger bond than if the parts are butt-welded. The sections are desirably made from the same polymer and are desirably substantially transparent or clear to visible light so that cameras or other observation means may be used to inspect the tracheal walls through the tracheostomy tube without removing it from the patient.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Multi-disc clutch assembly

The invention discloses a multi-disc clutch assembly. The multi-disc clutch assembly comprises an assembly base plate, an internal spline pressure plate and a thrust limit spiral cam, wherein the assembly base plate is connected with the internal spline pressure plate in a mutual embedding manner, a through hole is formed in the middle of the assembly base plate, a group of guiding posts are symmetrically arranged around the periphery of the through hole, and a plurality of outer tooth friction plates and inner tooth lining plates are arranged alternately on the outer side of the assembly base plate in an overlapping manner. A protruding part which extends out of the through hole and round hole parts in clearance fit with the guiding posts are arranged on the internal spline pressure plate. One side of the thrust limit spiral cam is fixed with the assembly base plate, and a cam is arranged at the end part of the other side, and springs are further arranged on the guiding posts and between the internal spline pressure plate and the thrust limit spiral cam. The multi-disc clutch assembly has the advantages of having infinitely increased friction area, good joint surface, fast separation, no impact, stable torque force values and the like after being used for transmitting torques, reducing axial pressure in comparison with the prior art to facilitate smooth and steady mechanical transformation of driving and climbing, and further having higher sensitivity, low cost and more reliable structure.

Owner:黄山奔马集团有限公司

An asphalt-based composite material for pavement crack repair

The invention discloses an asphalt base composite material for pavement crack repair. The asphalt base composite material for pavement crack repair is prepared from a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 120-150 parts of anionic emulsified asphalt, 1-3 parts of water reducing agent, 1-3 parts of defoaming agent, 3-8 parts of binder and 0-10 parts of water, and the component B comprises the following raw materials in parts by weight: 100 parts of cement, 70-110 parts of sand and 0.01-0.06 part of expanding agent. The asphalt base composite material for pavement crack repair has the flexibility of asphalt, the rigidity of cement and certain strength, is used for crack pouring and can bear and transfer loading force; the binder is added to the material so as to play a role of reinforcing the binding force between the material and crack walls, so that the service life of a pavement is prolonged, and the re-cracking phenomenon is difficult to occur. The asphalt base composite material for pavement crack repair has the advantages of low cost price, simple construction, low requirements on constructors, low energy consumption, low cost, strong binding power and long useful life and can be widely applied to the pavement crack repair.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

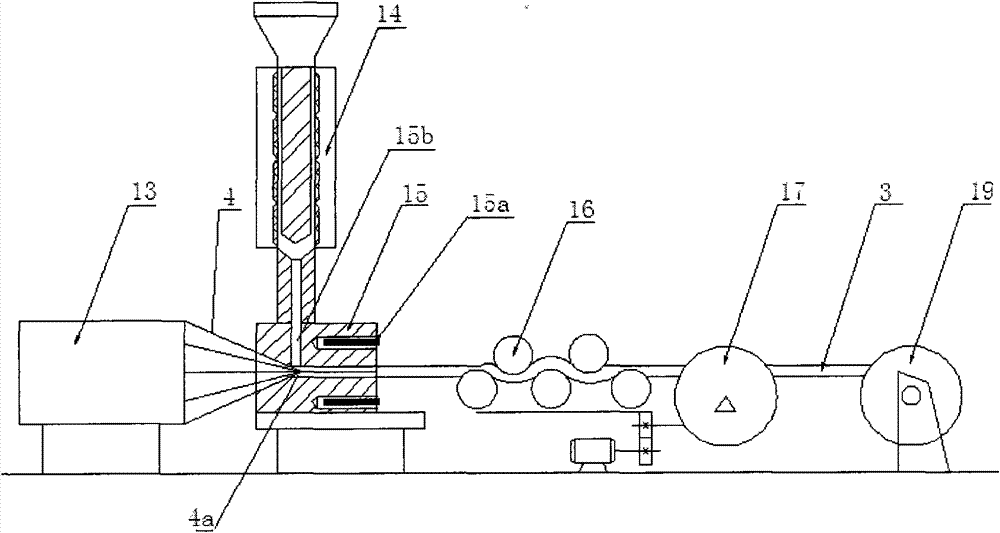

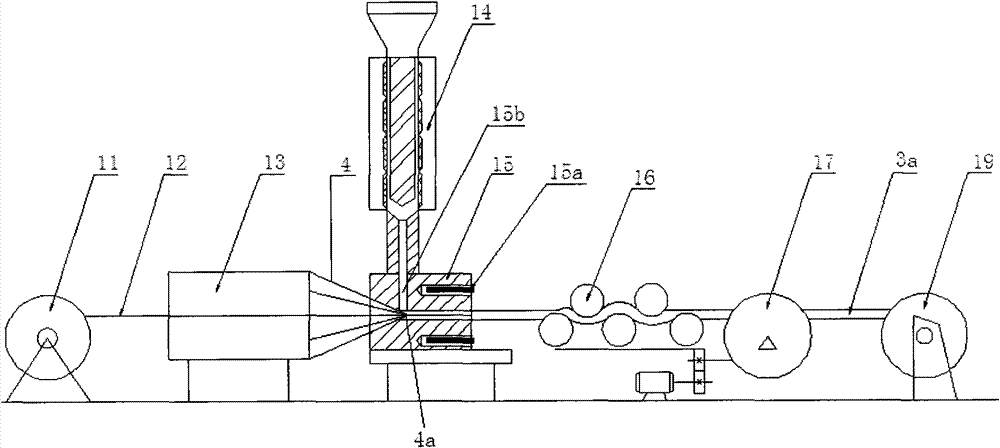

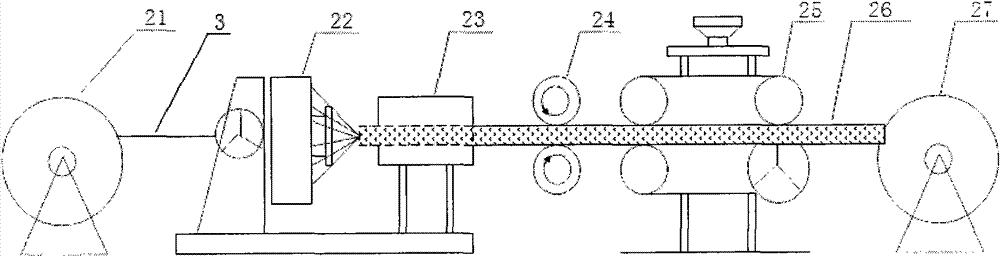

Method for manufacturing flexible oil pumping rope

ActiveCN102234943BEven by forceGood bonding surfaceRope making machinesCommunication cablesSteel ropePetroleum engineering

Owner:哈尔滨景宽科技开发有限公司

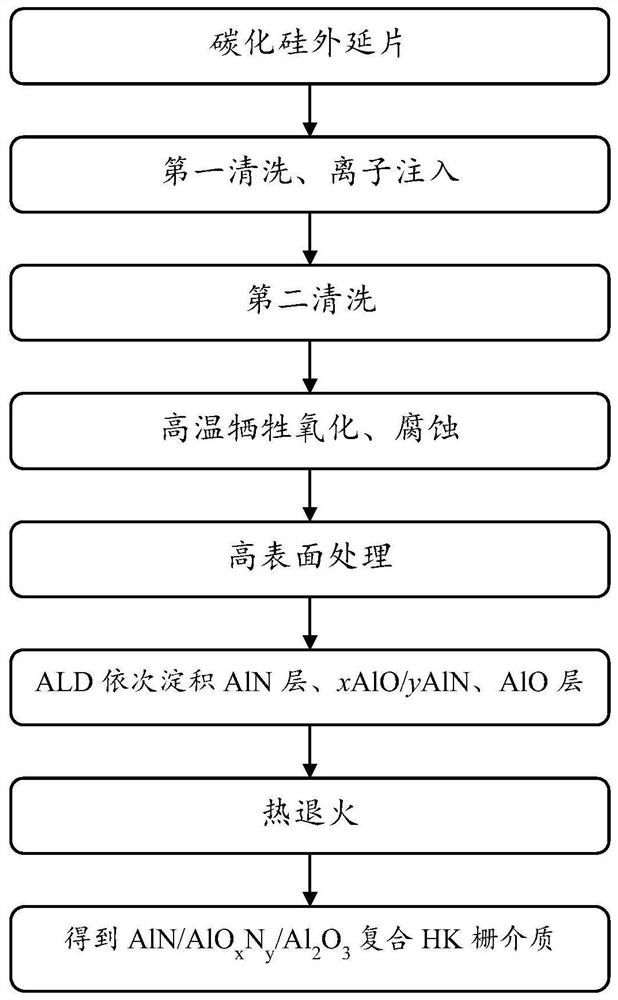

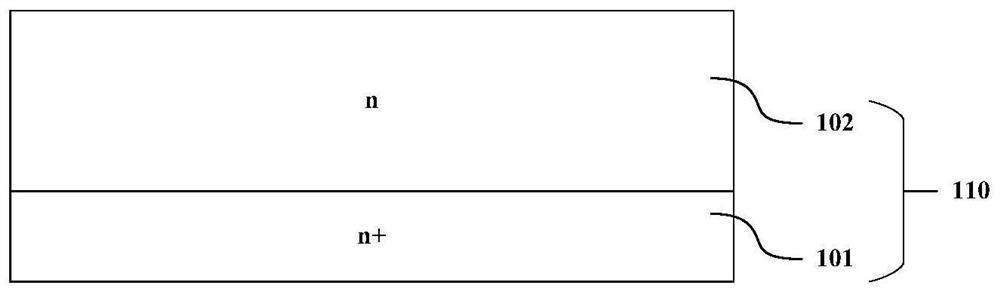

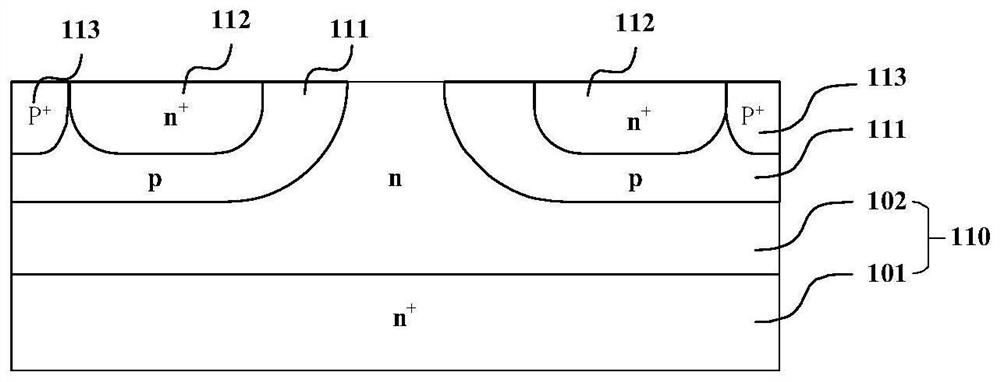

High-dielectric-constant gate dielectric material and preparation method thereof

PendingCN111640794AImprove interface qualityHigh interface state densityMaterial nanotechnologyNanoinformaticsPhysicsComposite material

The invention belongs to the technical field of semiconductor device preparation, and particularly relates to a high-dielectric-constant gate dielectric material and a preparation method thereof. Thehigh-dielectric-constant gate dielectric material comprises an AlN layer, an AlOxNy layer and an Al2O3 layer which are sequentially stacked from bottom to top. The gate dielectric layer has relativelyhigh interface quality, interface state density and high reliability, and meanwhile, the gate dielectric layer is relatively good in uniformity and relatively few in current leakage problem.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Electric motorcycle inner rotor motor friction plate self-adaptive automatic separation drive assembly

ActiveCN105947102BSimple structureQuick assemblyFriction clutchesVehicle transmissionAxial pressureElectric machine

The invention discloses a friction plate type self-adapting automatic separation driving assembly of an inner rotor motor of an electric motor cycle. The friction plate type self-adapting automatic separation driving assembly comprises a driving motor, a tank body, and a main shaft which is matched with the tank body in a rotating manner and outputs power, and further comprises a gear base, a clutch assembly, a first-stage gear, a transmission unit, a one-way gear and a one-way limiting screw cam. According to the friction plate type self-adapting automatic separation driving assembly disclosed by the invention, a novel plane type clutch assembly is used for transmitting torque, so that the friction plate type self-adapting automatic separation driving assembly has the advantages of being simple in structure, fast and convenient to assemble, easy to process, good in joint surface, fast in separation, free from impact, stable in torque force value, and the friction area can be infinitely increased. Through adjusting the number of external tooth friction pieces and the number of inner tooth liners and / or adjusting torque, nuts are adjusted to meet different requirements for the torque; when the torque is greater than a calibration value of the clutch assembly, the one-way limiting screw cam drives a thrust limiting screw cam, so that the external tooth friction pieces and the inner tooth liners are mutually loosened, the situation that the pressure in an axial direction is infinitely increased is effectively limited, the situation that the axial pressure of the main shaft is lower than 5000N is guaranteed, and the damage of a bearing on the main shaft is avoided.

Owner:黄山奔马集团有限公司

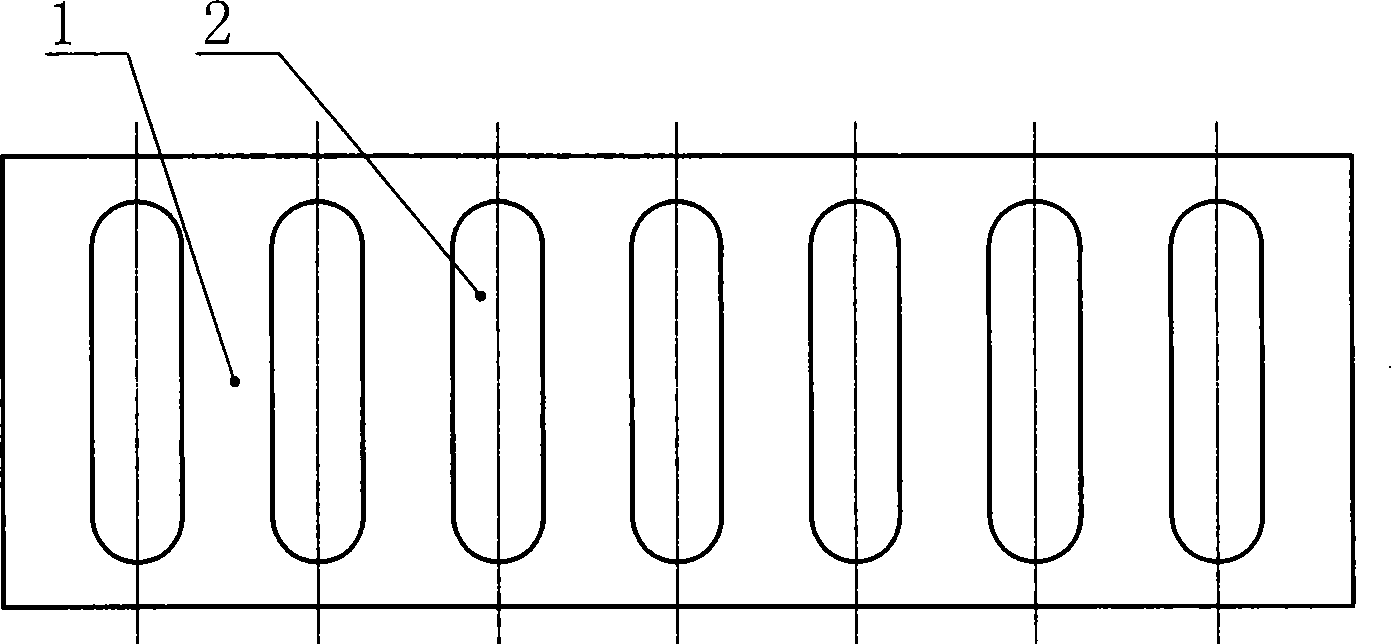

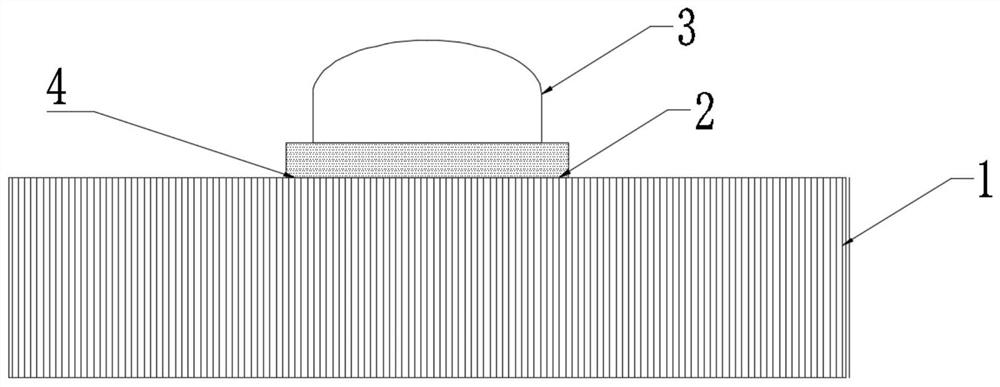

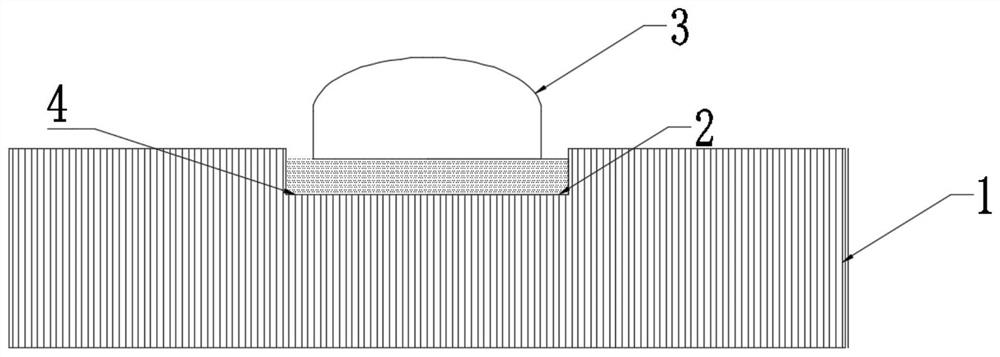

Method for manufacturing reactor coil wire lead

ActiveCN101299395BImprove connection strengthTo avoidTransformers/inductances coils/windings/connectionsCoils manufactureSurface oxidationAluminum foil

The invention discloses a manufacturing method of the reactor loop lead wires in the technical field of the reactor, including the following steps: first performing the high temperature anneal process on the strip sheet copper row; then fetching the aluminum foil with the same shape with the copper row, removing the surface oxide layer of the copper row and the aluminum foil; finally performing the cold crimping on the press machine with the copper row and the aluminum foil. The upper die is arranged with a plurality of strip ridge heave arranged in parallel, while the lower die is the rigid flat. The copper row and the aluminum foil are arranged between the upper die and the lower die, wherein the aluminum foil is up and the copper row is down, through the matched molds, the pressure maintaining, the demould, the copper row and the aluminum foil pressed together are fetched, namely the reactor loop lead wires. The method can connect the two materials reliably, with reliable connection and large tensile strength, no electrochemistry rot, no welding, high cleanness, low cost. The obtained product can be used for manufacturing the reactor.

Owner:艾博白云电气技术(扬州)有限公司

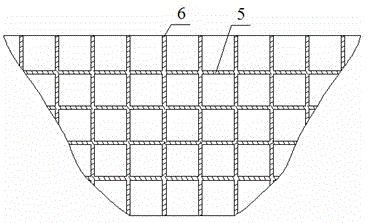

Method and equipment for pressing granulated aggregate into synthetic plate

ActiveCN101767366AControl and guide the direction of movementGood bonding surfaceCeramic shaping apparatusMaterials preparationEngineering

The invention relates to a method and equipment for pressing granulated aggregate into a synthetic plate. The method comprises the steps of material preparation, pavement and plate manufacture; and the method is characterized in that: in the plate manufacture step, each square meter of the granulated aggregate are vibrated by 240 to 450 KN exciting force in a vacuum state and are applied with pressure during vibration. In the technical scheme provided by the invention, the 240 to 450 KN exciting force is adopted to apply to each square meter of the granulated aggregate in the pressing process and granules with different sizes can be the pressed. The vibrating frequency is adjusted to make the granules have multidirectional movement, and optimal combination surfaces can be found among the granules for arrangement. The pressure is applied while the exciting force is applied; gaps among the granules are continuously compressed; in the pressure application process, the exciting force with the vibrating frequency can well control and guide the moving direction of the granulated aggregate to make geometric surfaces of the granulated aggregate occluded with each other.

Owner:ANHUI UISTONE GREEN MATERIAL HI TEC CO LTD

Secondary injection molding process of megawatt level wind turbine blades

ActiveCN102001185BImprove quality and efficiencyIncrease productivityDomestic articlesVacuum pumpingTurbine blade

Owner:SINOMATECH WIND POWER BLADE

A split-type adaptive automatic torque-increasing energy-saving drive assembly for electric vehicles

ActiveCN105805278BSimple structureQuick assemblyGearing controlGearing detailsAxial pressureEngineering

The invention discloses a split self-adaption automatic torque adding and energy saving driving assembly for an electric vehicle. The assembly comprises a box, a main shaft, a power input gear, a gear shaft, a clutch assembly, a gear base, a first-grade gear, a transmission unit, a one-way gear and a one-way limiting spiral cam. The split multi-clutch assembly is adopted to transmit the torque, and has such advantages as simple structure, fast assembly, easy machining, capability of infinitely increasing the friction area, good combining surface, fast separation, no impact and stable torque value. Different torque demands are adapted through adjusting the numbers of outer tooth friction pieces and inner tooth lining plates and / or adjusting torque adjusting nuts; and in addition, a thrust limiting spiral cam is pushed by the one-way limiting spiral cam to release the outer tooth friction pieces from the inner tooth lining plates, so that the axial infinite pressurization is limited, the axial pressure of the main shaft is lower than 5000 N, and the damage of a bearing on the main shaft is prevented. The assembly reduces the axial pressure, and has such advantages as stable driving-climbing mechanical conversion and high sensitivity.

Owner:黄山奔马集团有限公司

Organic light-emitting diode frit glue packaging structure and manufacturing method thereof

PendingCN113659094ALiquidityGood bonding surfaceSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoSemiconductor package

The invention discloses an organic light-emitting diode frit glue packaging structure and a manufacturing method thereof. The organic light-emitting diode frit glue packaging structure comprises a cover plate, a micro-nano thin layer and frit glue, wherein the micro-nano thin layer is arranged on the cover plate, and the frit glue is arranged on the micro-nano thin layer. The invention belongs to the technical field of semiconductor packaging, and particularly relates to the organic light-emitting diode frit glue packaging structure and the manufacturing method thereof. A micro-nano thin layer is added on the surface of the cover plate, and the combination surface of the frit glue and the cover plate is improved.

Owner:FUJIAN HUAJIACAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com