A split-type adaptive automatic torque-increasing energy-saving drive assembly for electric vehicles

A drive assembly, split technology, applied in the direction of automatic clutch, transmission control, transmission parts, etc., can solve the problems of unstable mechanical performance, high market maintenance rate, high manufacturing cost, and achieve high motor efficiency and simple structure. , the effect of quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

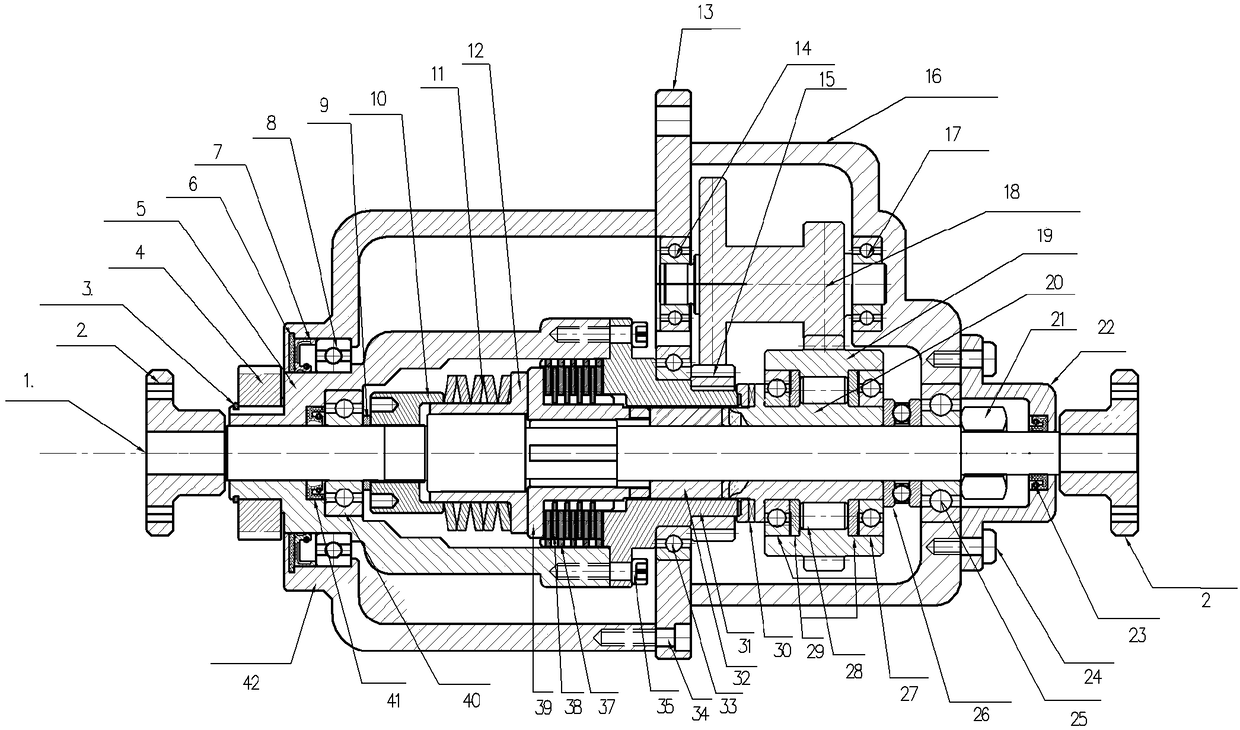

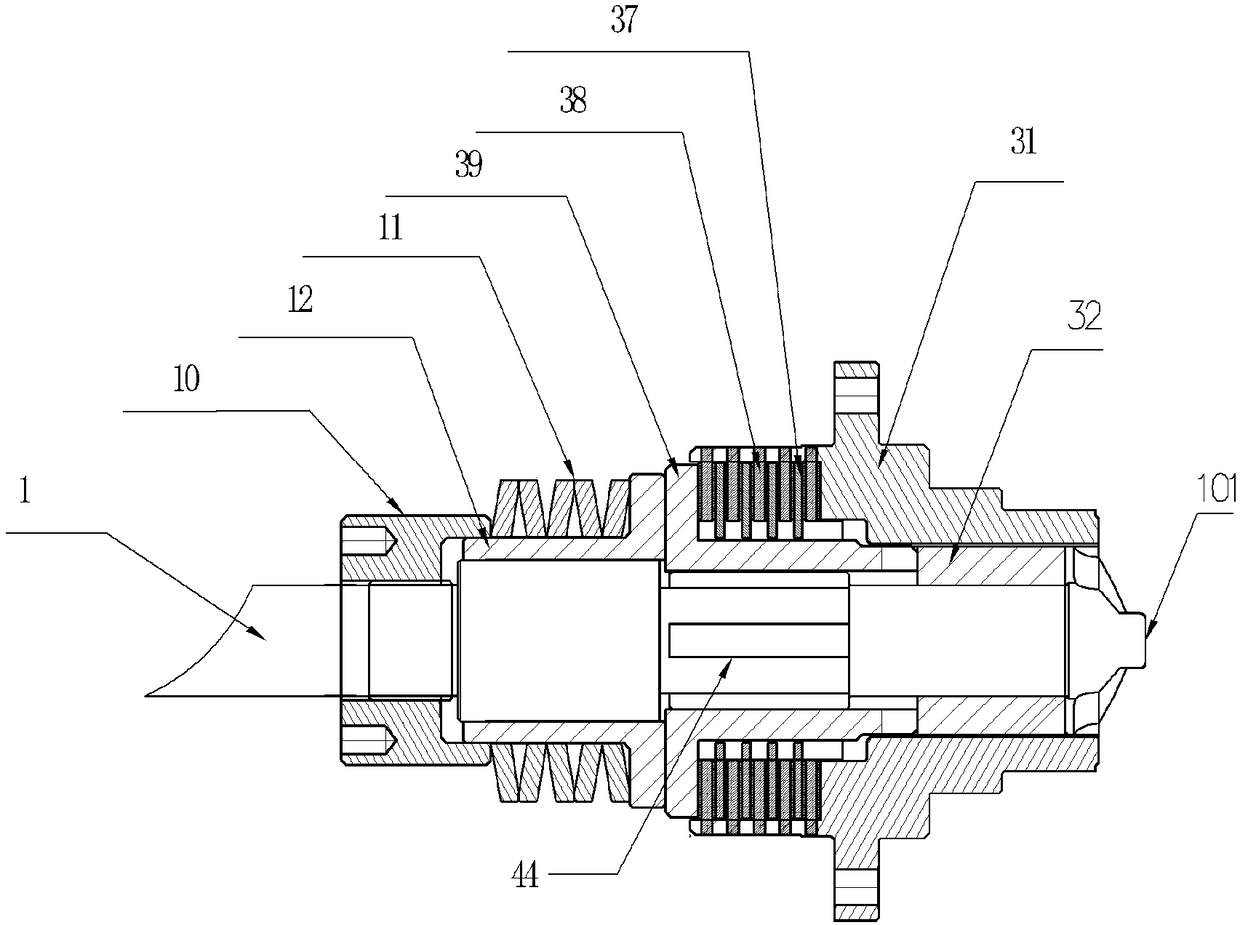

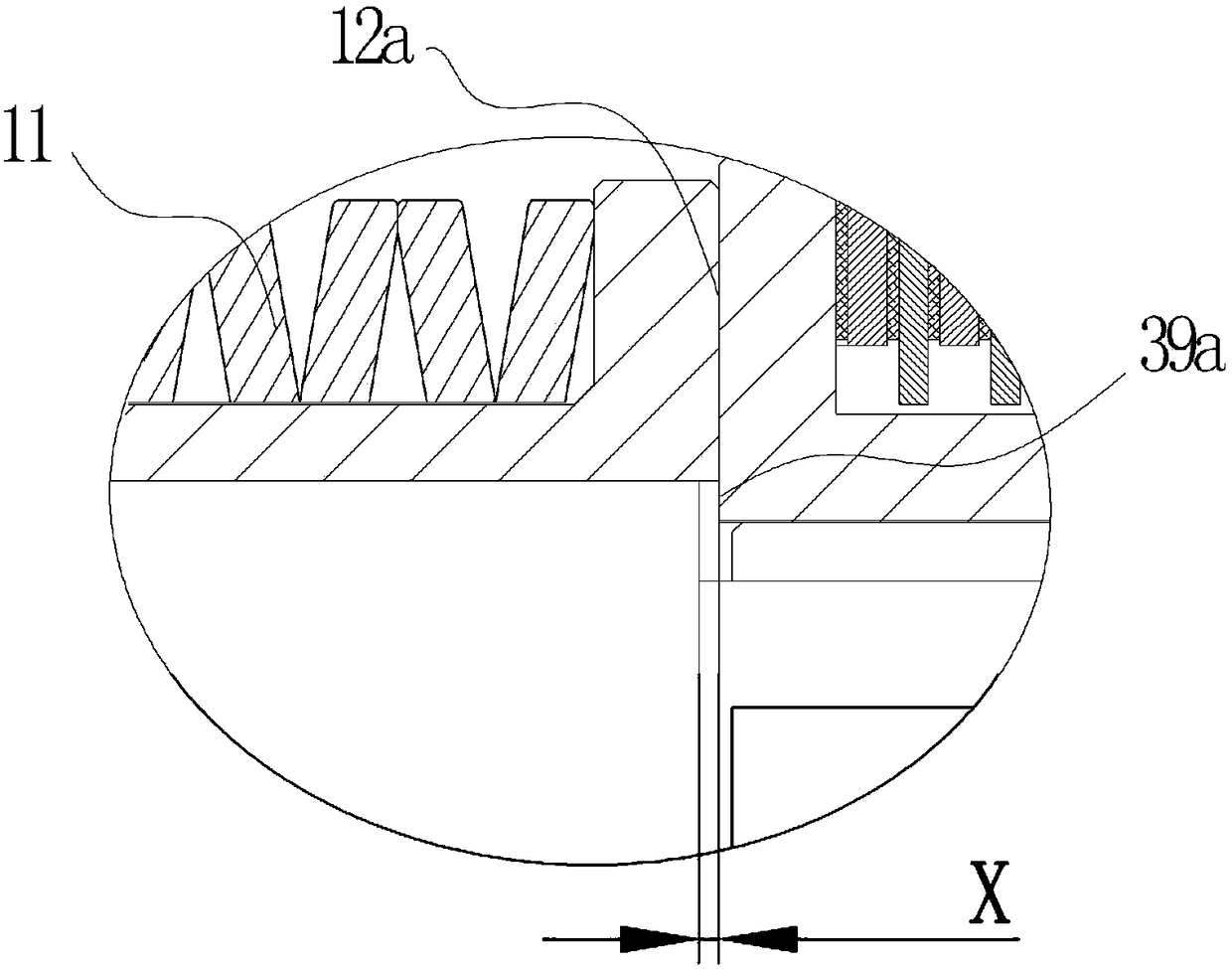

[0032] see Figures 1 to 4, a split-type adaptive automatic torque-increasing energy-saving drive assembly for an electric vehicle, comprising a box fixing plate 13, a left box 42, a right box 16, and a main shaft 1 that rotates and cooperates with the left and right boxes and outputs power, It also includes power input gear 4, gear shaft 5, clutch assembly, gear seat 31, primary gear 15, transmission unit, one-way gear 19 and one-way limiting helical cam 20.

[0033] The left box 42 is fixed on the left side of the box fixing plate 13, the right box 16 is fixed on the right side of the box fixing plate 13, the main shaft 1 extends from the left box 42 to the right box 16, and is fixed through the box plate 13. Connecting flanges 2 are respectively installed at the left and right ends of the main shaft 1 .

[0034] The power input gear 4 is arranged on the outside of the left box 42 , and cooperates with the external motor for transmission. A retaining spring I3 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com