Organic light-emitting diode frit glue packaging structure and manufacturing method thereof

A technology of light-emitting diodes and plastic sealing, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of OLED device failure, water and oxygen intrusion, and glue width and height, and achieves the goal of reducing water and oxygen intrusion. The effect of risk, enhanced interface bonding, and simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

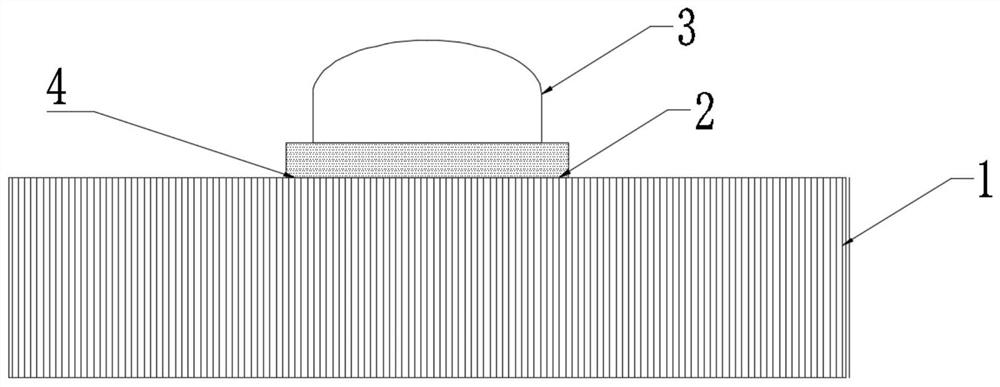

[0022] Such as figure 1 As shown, an organic light emitting diode frit glue packaging structure of the present invention includes a cover plate, a micro-nano thin layer and firt glue, the micro-nano thin layer is arranged on the cover plate, and the firt glue is arranged on the micro-nano thin layer ;The presence of micro-nano thin layer can improve the bonding surface between frit and cover plate, increase the contact angle between frit glue and cover plate before pre-sintering, so that the glue has fluidity while maintaining glue height; during sintering, frit-cover plate The interfacial bonding force between the glasses is strengthened, reducing the risk of water and oxygen intrusion and prolonging the life of OLED devices.

[0023] The cover plate is provided with a firt glue-filling channel; the micro-nano thin layer is arranged on the firt glue-filling channel by coating and chemical vapor deposition, and the micro-nano thin layer protrudes from the cover plate; A micro...

Embodiment 2

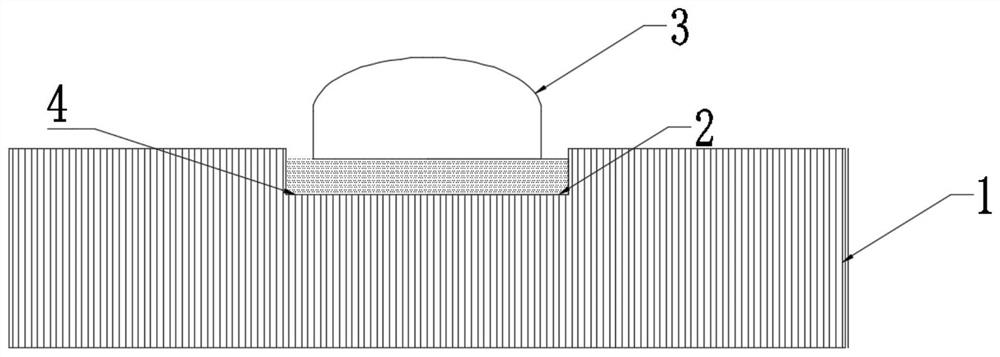

[0029] Such as figure 2 As shown, an organic light emitting diode frit glue packaging structure of the present invention includes a cover plate, a micro-nano thin layer and firt glue, the micro-nano thin layer is arranged on the cover plate, and the firt glue is arranged on the micro-nano thin layer ;The presence of micro-nano thin layer can improve the bonding surface between frit and cover plate, increase the contact angle between frit glue and cover plate before pre-sintering, so that the glue has fluidity while maintaining glue height; during sintering, frit-cover plate The interfacial bonding force between the glasses is strengthened, reducing the risk of water and oxygen intrusion and prolonging the life of OLED devices.

[0030] The cover plate is provided with a firt glue-filled channel, and the micro-nano thin layer is provided on the firt glue-filled channel through laser, corona, and etching. The micro-nano thin layer is embedded in the cover plate, and the micro-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com