High rock-fill dam membrane anti-seepage body on deep coverage layer and construction method of high rock-fill dam membrane anti-seepage body

A technology for high rockfill dams and deep overburden layers, applied in dams, barrages, water conservancy projects, etc., can solve problems such as high rockfill anti-seepage on deep overburden layers that cannot be effectively solved, and achieves convenient construction and simple structural types Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

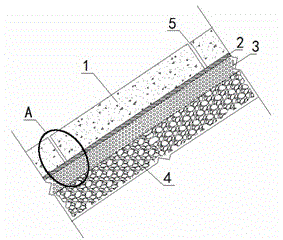

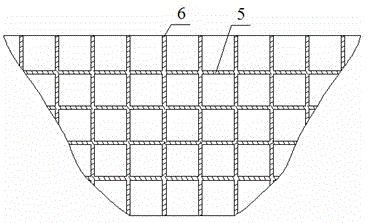

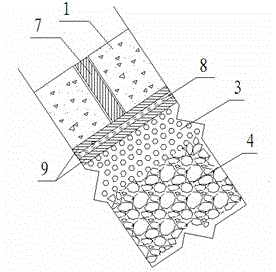

[0033] Such as Figure 1 ~ Figure 3As shown, a face mask anti-seepage body of a high rockfill dam on a deep covering layer is composed of a concrete protective layer 1, a geomembrane anti-seepage layer 2, a flexible cushion layer 3 and a transition layer 4. Protective layer 1 is the cast-in-place fiber concrete layer with horizontal joints 5 and vertical joints 6 reserved, with a thickness of 25-35 cm, a vertical and horizontal joint spacing of 10-15 m, a joint width of 1-2 cm, and asphalt filling in the joints Wooden strips 7; the geomembrane anti-seepage layer 2 is a composite geomembrane with two cloths and one membrane, the middle is a 0.5-1.5mm thick PVC light film 8, and the two sides are 500-1200g / m 2 Needle-punched filament geotextile 9; the bottom flexible cushion 3 is made of BASF It is poured after mixing polyurethane glue and gravel, with a thickness of 6-10 cm; a transition layer 4 of coarse grain materials is set between the flexible cushion layer 3 and the roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com