Environment-friendly composite waterproof membrane and production method thereof

A waterproofing membrane, environmentally friendly technology, used in textiles, papermaking, building components, etc., can solve the problems of self-heavy modified asphalt waterproofing membrane, low tear strength of finished products, poor anti-aging ability, etc., and achieve excellent durability. The effect of high resistance, high friction coefficient and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below.

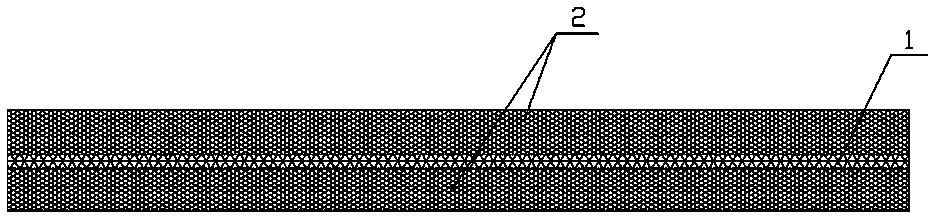

[0025] Such as figure 1 As shown, the environment-friendly composite waterproof coiled material of the present invention comprises a base 1 and a waterproof material layer 2 compounded on both sides of the base 2. In order to improve the tensile and tear strength of the finished coil, the base 1 adopts Polyester filament cloth (filament diameter 600D*600D), in order to ensure that the finished coil is environmentally friendly and pollution-free under the premise of meeting the service life and other indicators, the waterproof material layer 2 compounded on both sides of the tire base 1 is a polymer prepared from the following raw materials Polymer emulsion impregnation treatment:

[0026] Acrylate emulsion 40~60 parts,

[0027] 8~15 parts of TE film-forming aids,

[0028] AT-06 thickener 2~6 parts,

[0029] SE-2 antifungal agent 2~6 parts,

[0030] SPA-202 defoamer 2~6 parts,

[0031] 20~40 parts of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com