Multi-disc clutch assembly

A clutch and multi-plate technology, applied in the field of multi-plate clutch assembly, can solve the problems of complex processing technology, unstable mechanical performance, and inconvenient torque adjustment of the clutch assembly, and achieve mechanical transmission design optimization and stable mechanical conversion , The effect of stable torque value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

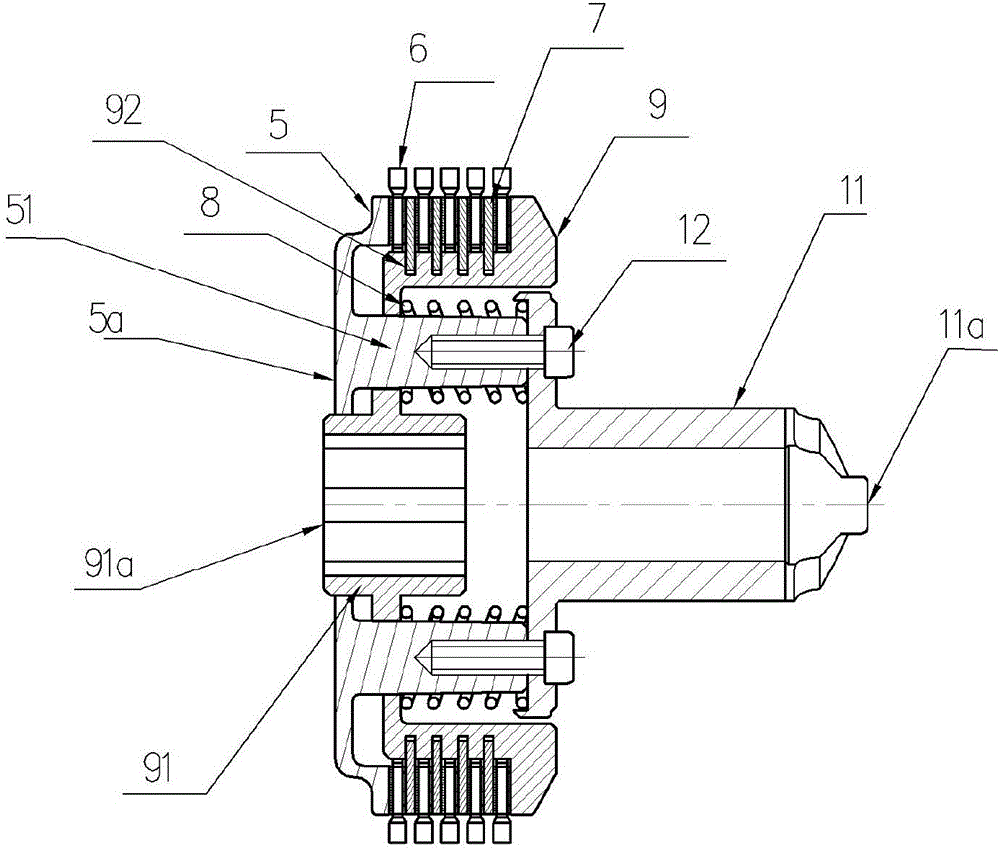

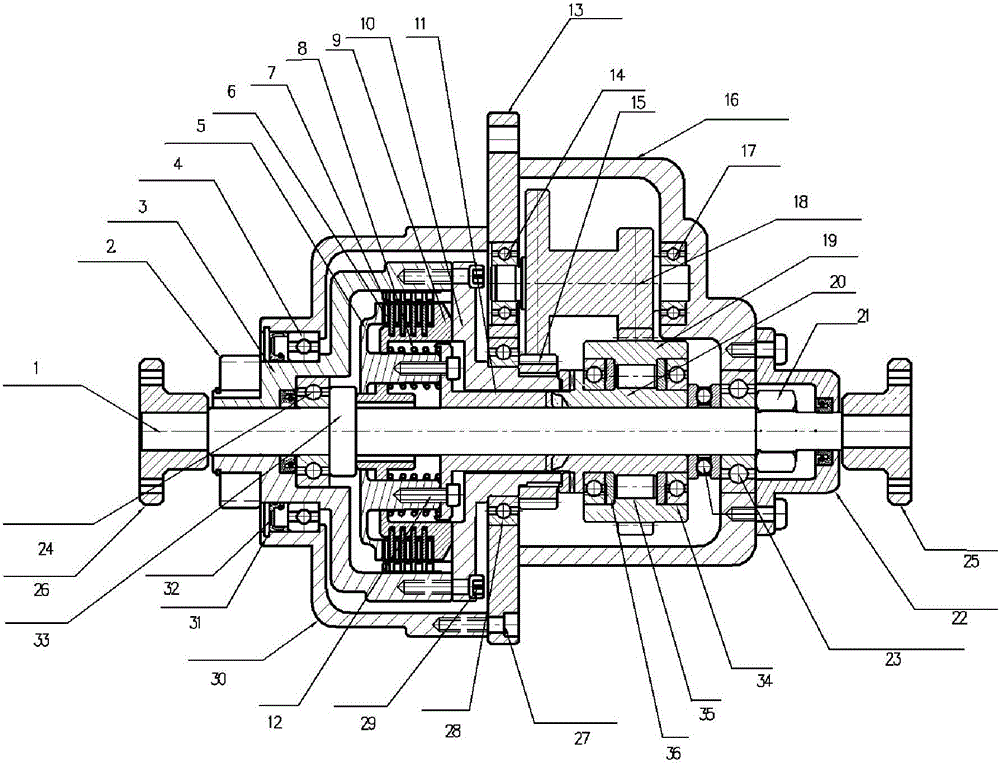

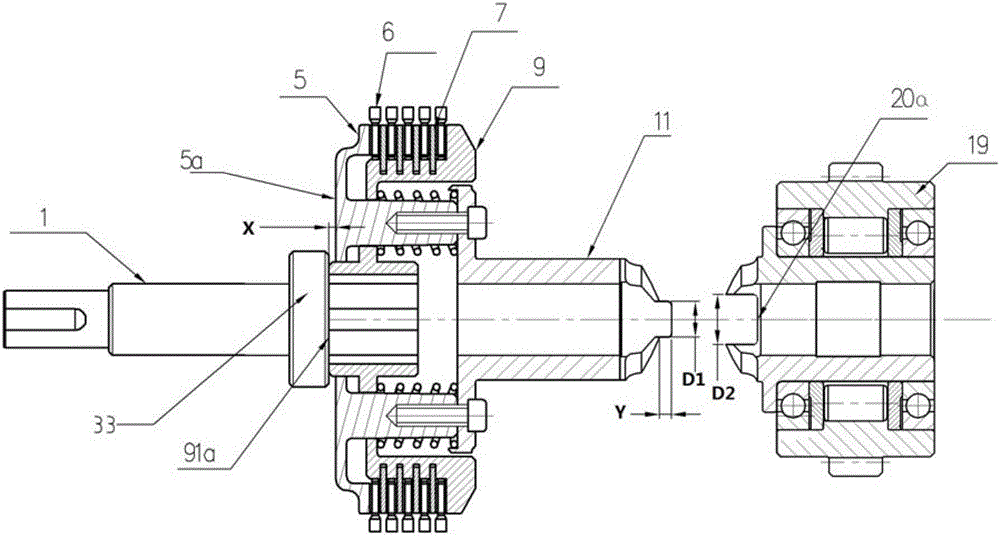

[0026] see Figures 1 to 3 , an adaptive automatic torque-increasing energy-saving drive assembly for electric vehicles, including a box body fixing plate 13, a box body 30, a gear cover 16, and a main shaft 1 that rotates with the box body 30 and outputs power, and also includes a power input Gear 2, gear shaft 3, clutch assembly, gear seat 10, primary gear 15, transmission unit, one-way gear 19 and one-way limiting helical cam 20.

[0027] The box body 30 is fixed on the left side of the box body fixing plate 13 , the gear cover 16 is fixed on the right side of the box body fixing plate 13 , the main shaft 1 extends from the box body 30 to the gear cover 16 direction, and runs through the box body fixing plate 13 . A left flange 26 is installed on the left end of the main shaft 1, and a right flange 25 is installed on the right end.

[0028] The power input gear 2 is arranged outside the box body 30 and cooperates with the external motor for transmission. Driven by the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com