Friction plate type self-adapting automatic separation driving assembly of inner rotor motor of electric motor cycle

A technology for inner rotor motors and electric motorcycles, applied in the direction of friction clutches, mechanical drive clutches, clutches, etc., can solve the problems of unstable mechanical performance, high market maintenance rate, high manufacturing cost, etc., and achieve high motor efficiency, simple structure, The effect of quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

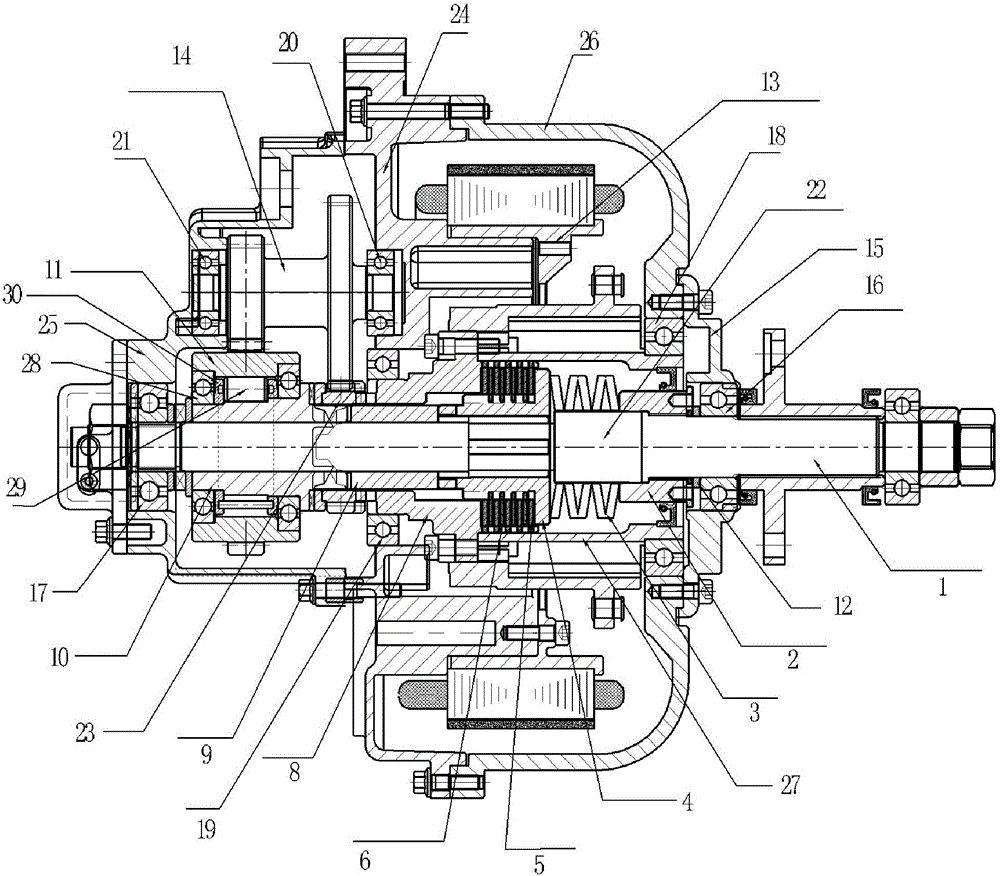

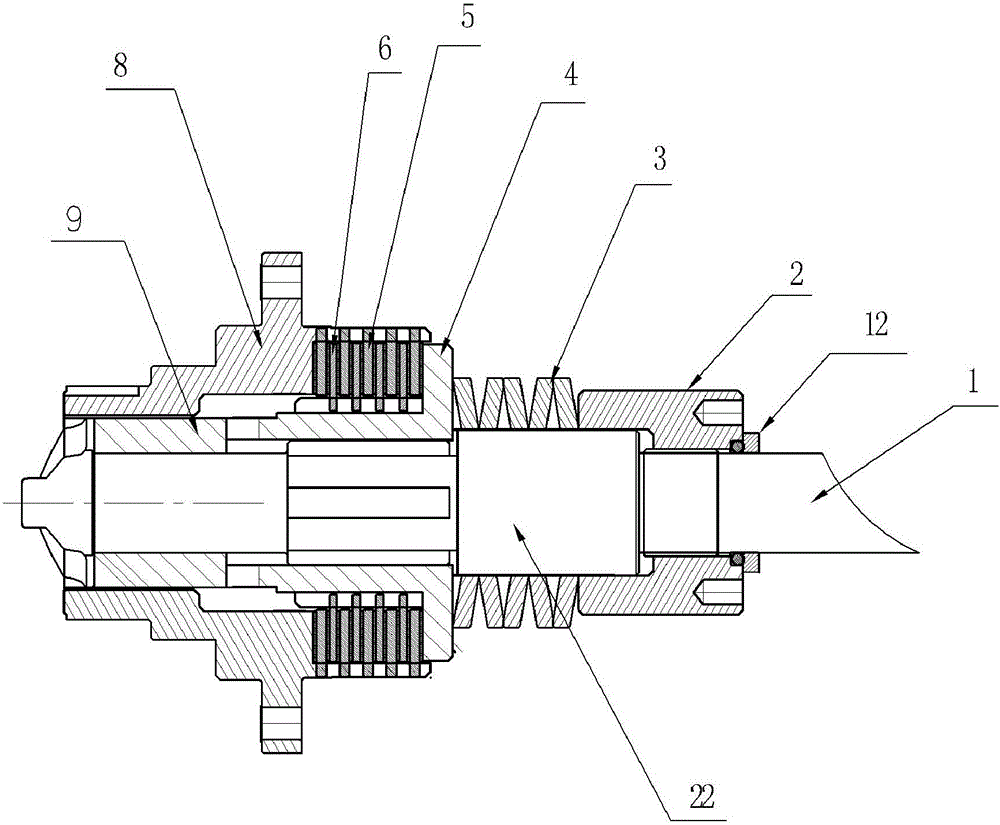

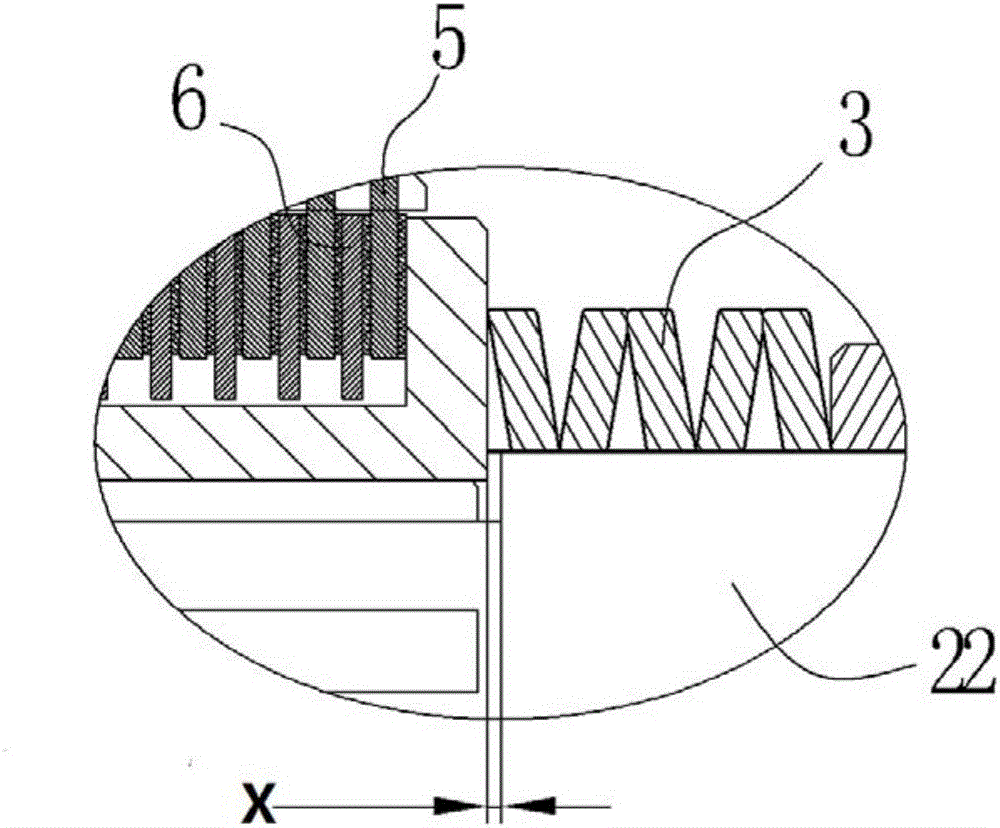

[0030] see picture 1 to 4 ,A sort of Friction plate self-adaptive automatic separation drive assembly for electric motorcycle inner rotor motor , including a drive motor 13, a box body and a main shaft 1 that rotates with the box body and outputs power, and also includes a gear seat 8, a clutch assembly, a primary gear 23, a transmission unit, a one-way gear 11 and a one-way limit screw cam10.

[0031] Wherein, the box body comprises box body fixing plate 24, is positioned at the left box body 25 of box body fixing plate 24 left sides, and is positioned at the right box body 26 of box body fixing plate 24 right sides, right box body 26 and box body fixing plate 24 Fastening is done with screws.

[0032]The main shaft 1 extends from the left box 25 to the right box 26 and passes through the box fixing plate 24 . A gland 15 fixed by screws is also provided outside the right box body 26 , and a first spindle bearing 16 is installed between the gland 15 and the spindle 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com