Horizontal well gravel packing tool

A gravel packing, horizontal well technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of lax closing of the filling port of the packing tool, pipe string channeling, and gravel recovery, etc. The effect of less heavy labor, avoiding gravel taking, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

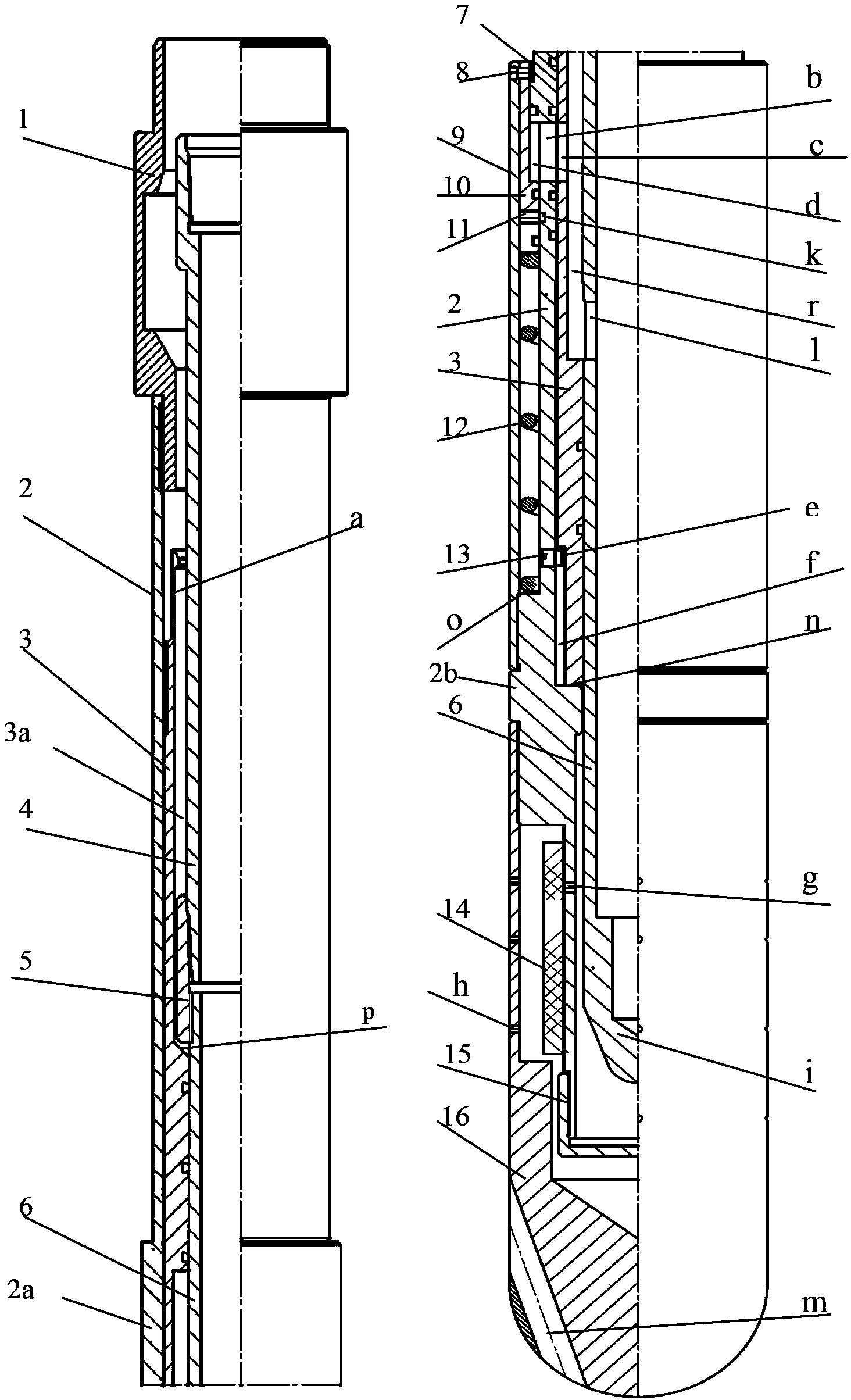

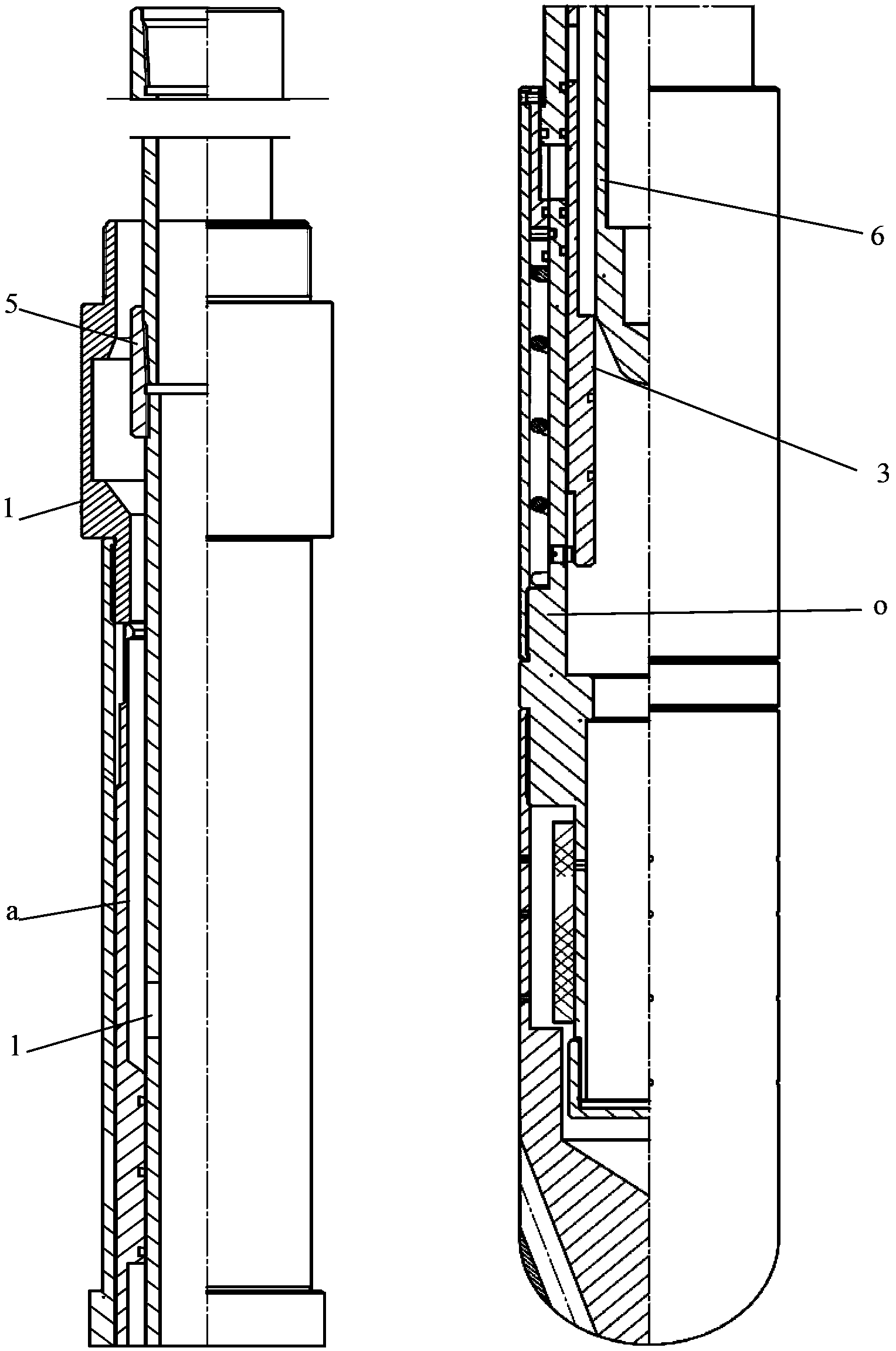

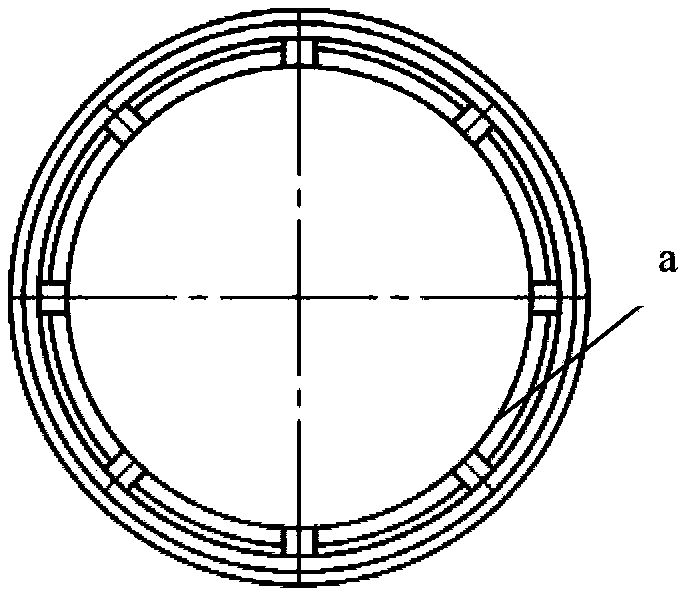

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see Figure 1-Figure 4b The horizontal well gravel packing tool includes: connecting collar 1, outer cylinder 2, liner 3, upper core pipe 4, core pipe collar 5, lower core pipe 6, outer cylinder centralizer 7, limit screw 8, spring Sleeve 9, sliding sleeve 10, shear nail 11, spring 12, liner guide 13, wire wrapping screen 14, wire plug 15 and guide head 16.

[0024] The connecting collar 1 has an upper joint and a lower joint, which are used for threaded connection with the tool pipe string and the outer cylinder 2 respectively.

[0025] The outer cylinder 2 has an upper joint and a lower joint, which are threadedly connected with the oil pipe collar 1 and the plug 15 respectively. The middle part of the outer cylinder 2 protrudes outward along the circumferential direction to form a first boss 2 a, and the first boss 2 a has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com