Preparation method of corn stigma extract for cigarettes

A corn silk extract and corn silk technology are applied in the field of preparation of corn silk extract for tobacco, and achieve the effects of increasing sweetness, increasing aroma, and reducing negative stimulating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

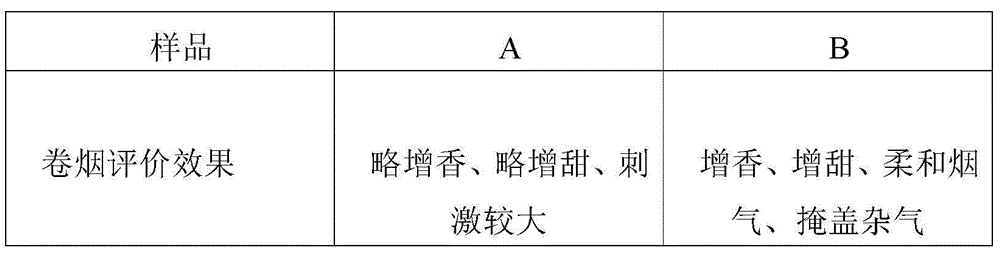

Examples

Embodiment 1

[0023] (1) Take corn silk and grind it through a 80-mesh sieve, mix corn silk with water at a mass ratio of 1:15, then control the ultrasonic frequency to 50KHz for 30 minutes, and then use NaAc-HAc solution to sonicate the resulting mixture The pH of the mixture was adjusted to 5, and then the mixture was allowed to stand for 8 hours to pass through a 0.8 μm filter membrane to obtain a filtrate, and the obtained filtrate was concentrated to half of the total mass of corn silk and water at the beginning to obtain sample No. 1 of corn silk extract;

[0024] (2) Grind corn silk with the same quality as in step (1) and pass through an 80-mesh sieve, mix the corn silk with an ethanol solution with a volume fraction of 70% in a mass ratio of 1:50, and then mix the resulting mixture Adjust the microwave power to 200W at 70°C for microwave extraction for 9 minutes, and then pass the obtained extract through a 0.8 μm filter membrane to obtain the filtrate obtained as the No. 2 sample o...

Embodiment 2

[0027] (1) Take corn silk and grind it through a 80-mesh sieve, mix corn silk with water at a mass ratio of 1:17, then control the ultrasonic frequency to 35KHz for ultrasonic treatment for 20 minutes, and then use NaAc-HAc solution to sonicate the resulting mixture The pH of the mixture was adjusted to 5, and then the mixture was allowed to stand for 8 hours to pass through a 0.8 μm filter membrane to obtain a filtrate, and the obtained filtrate was concentrated to half of the total mass of corn silk and water at the beginning to obtain sample No. 1 of corn silk extract;

[0028] (2) Grind corn silk with the same quality as in step (1) and pass through an 80-mesh sieve, mix the corn silk with an ethanol solution with a volume fraction of 60% in a mass ratio of 1:40, and then mix the resulting mixture Adjust the microwave power to 350W at 60°C to carry out microwave extraction for 8 minutes, and then pass the obtained extract through a 0.8 μm filter membrane to obtain the filtr...

Embodiment 3

[0031] (1) Take corn silk and grind it through a 80-mesh sieve, mix corn silk with water at a mass ratio of 1:20, then control the ultrasonic frequency to 25KHz for ultrasonic treatment for 15 minutes, and then use NaAc-HAc solution to sonicate the resulting mixture The pH of the mixture was adjusted to 6, and then the mixture was left to stand for 10 hours and then passed through a 0.8 μm filter membrane to obtain a filtrate, and the resulting filtrate was concentrated to half the total mass of the initial corn silk and water to obtain the corn silk extract No. 1 sample;

[0032] (2) Grind corn silk with the same quality as in step (1) and pass through an 80-mesh sieve, mix the corn silk with an ethanol solution with a volume fraction of 50% in a mass ratio of 1:30, and then mix the resulting mixture Adjust the microwave power at 50°C to 500W for microwave extraction for 6 minutes, and then pass the obtained extract through a 0.8 μm filter membrane to obtain the filtrate obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com