Roll cleaning device

A cleaning device and counter-roller technology, which is applied in transportation and packaging, thin material handling, instruments, etc., can solve problems such as instability and difficulties, and achieve the effect of reducing changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

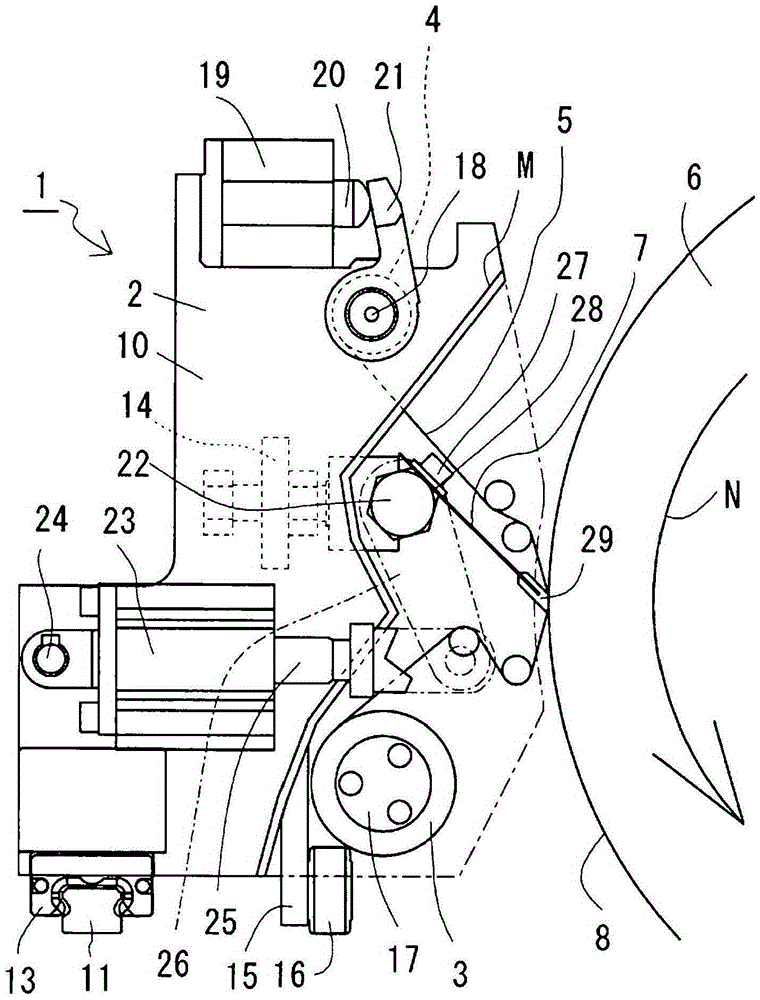

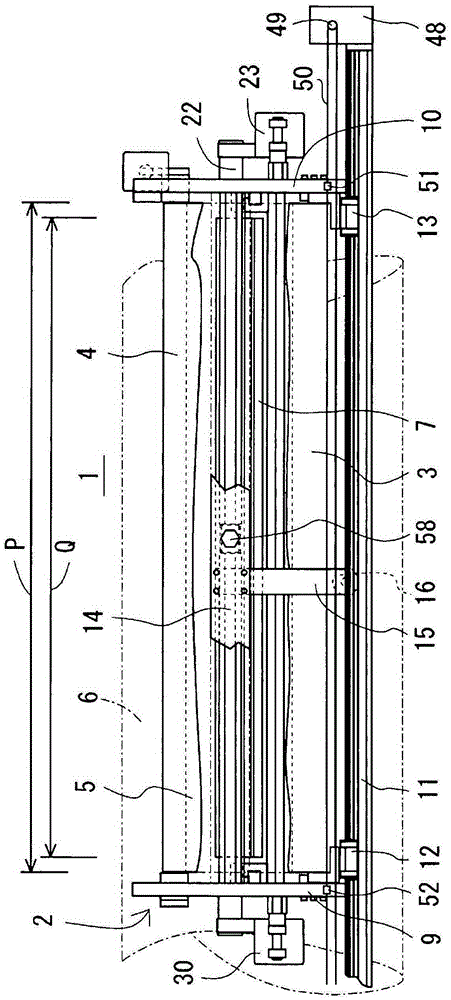

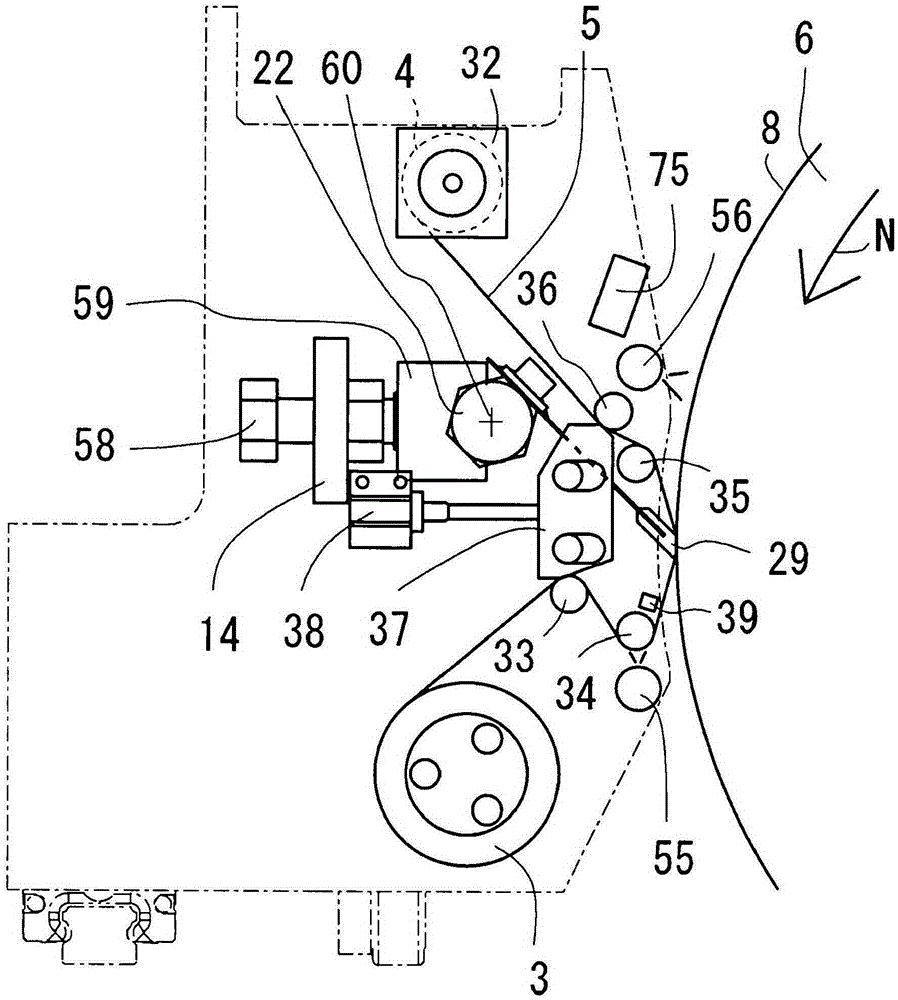

[0061] figure 1 It is a side view of the first embodiment of the present invention. figure 2 and Figure 4 yes figure 1 Front view of an embodiment of the invention shown. 1 is a roller cleaning device. Reference numeral 6 denotes a roller to be cleaned by the roller cleaning device 1 . In addition, the roller 6 is also sometimes referred to as an air cylinder. N is an arrow indicating the direction of rotation of the roller 6, in figure 1 , turn it counterclockwise. 2 is a cleaning unit. The cleaning unit 2 supports the main components of the roller cleaning device 1 .

[0062] exist figure 1 In FIG. 2 , in order to describe the internal structure of the cleaning unit 2 , a part of the structure is exposed by a break line M in the drawings. 5 is a cleaning cloth. 3 is a supply member for supplying the cleaning cloth 5 . Reference numeral 4 denotes a winding member for winding the cleaning cloth 5 supplied from the supply member 3 . 7 is a pressing body for press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap