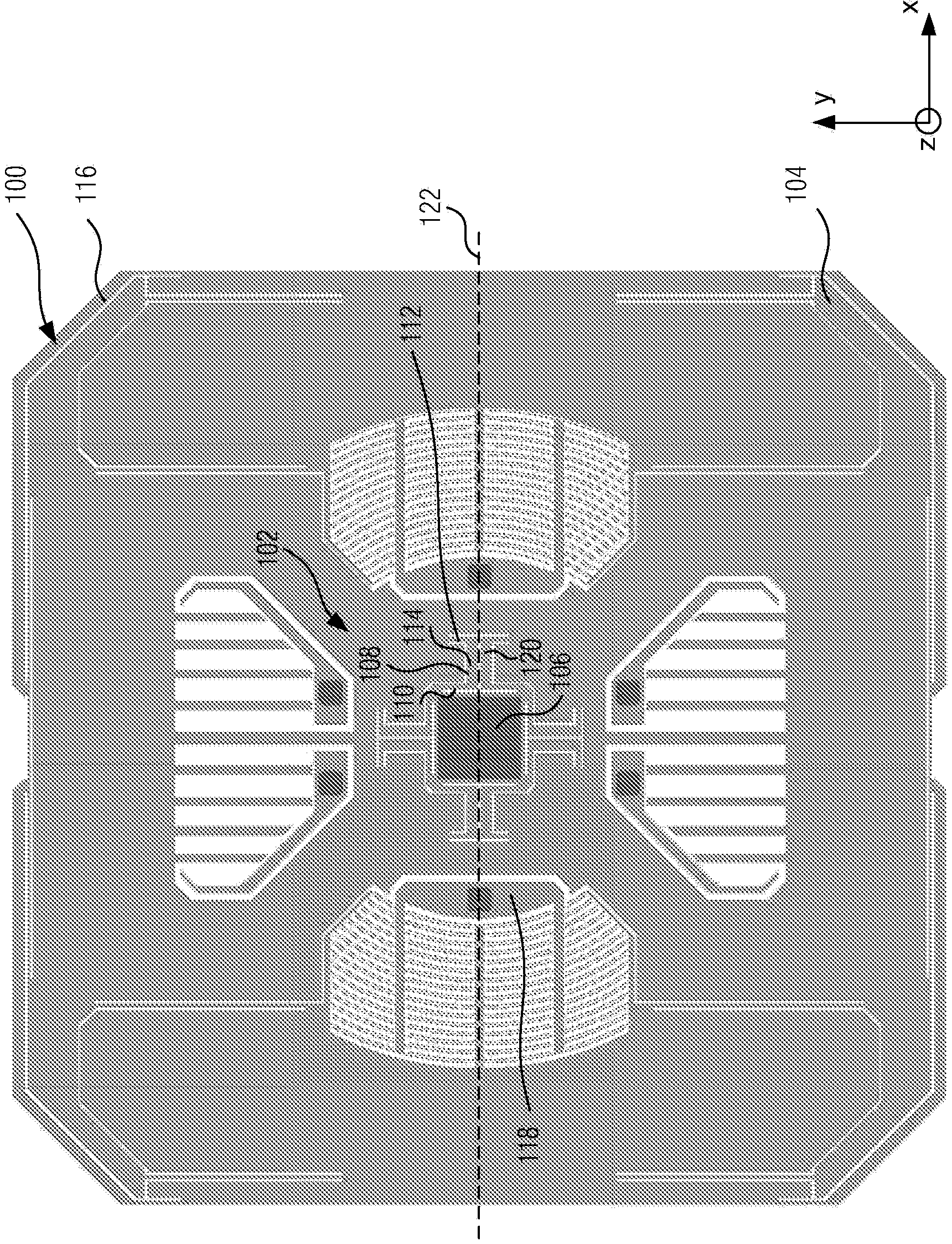

Flexure bearing to reduce quadrature for resonating micromachined devices

A fixed part, inner part technology applied in the field of deflection bearings for reducing steering deviation for resonant microfabrication devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

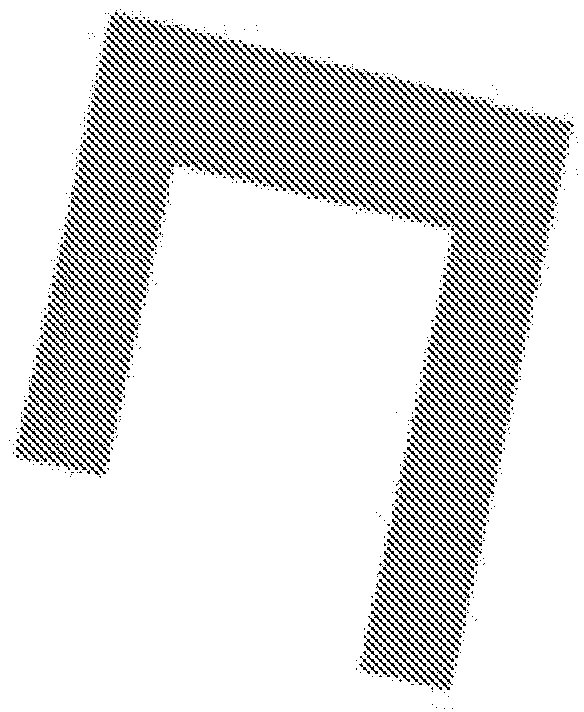

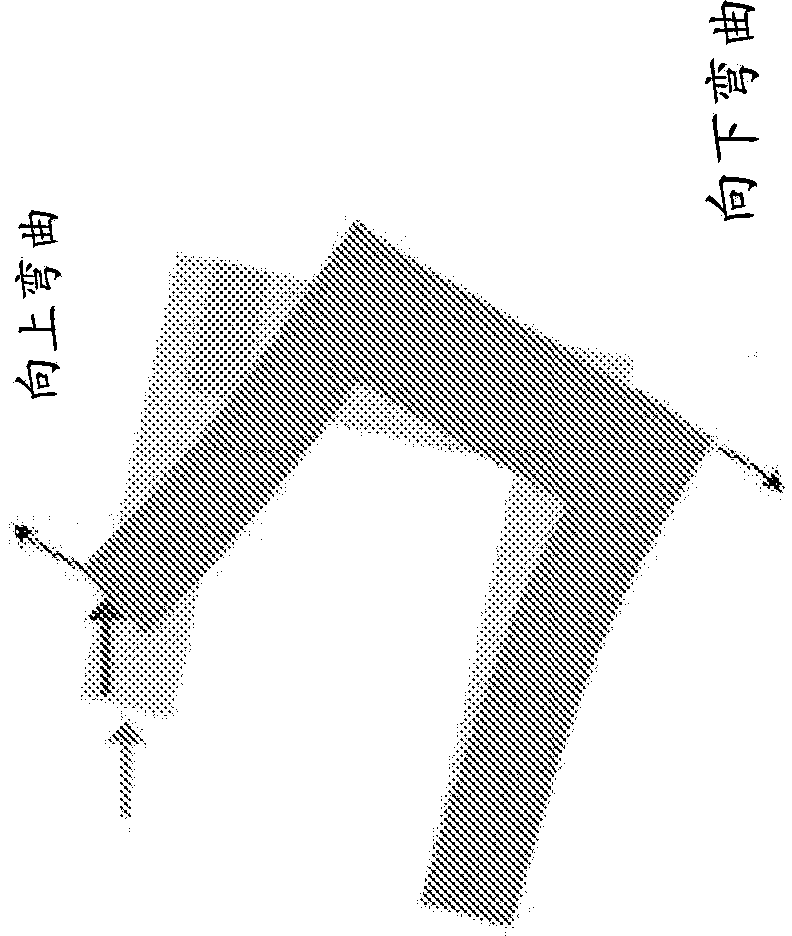

[0062] Example 2 includes the subject matter of Example 1, wherein the first nonlinear suspension member is C-shaped.

example 3

[0063] Example 3 includes the subject matter of Example 2, wherein the C-shape includes an inner portion connected to the anchor and extending toward the anchor bisecting plane and a central portion having a proximal portion and a distal portion, wherein the proximal A portion is connected to the inner portion, and the distal portion extends away from the anchor along the anchor bisecting plane and is connected to an outer portion extending away from the anchor bisecting plane.

example 4

[0064] Example 4 includes the subject matter of Example 3, wherein said outer portion of said first nonlinear suspension member has a proximal portion connected to said central portion of said first nonlinear suspension member, and extends away from said a distal portion of an anchor bisecting plane; a fourth portion of said first nonlinear suspension member connected at its proximal portion to said distal portion of said outer portion and extending toward said anchor to A distal portion of the fourth portion connected to a fifth portion of the first nonlinear suspension member extending toward the anchor bisecting plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com