Microwave shrinkage type connection structure of combined structure and construction technology

A composite structure and connection structure technology, which is applied in the direction of load-bearing elongated structural members, structural elements, building components, etc., can solve the problem that the flange plate cannot shrink, affect the overall structural strength of the composite structure, and the peeling of steel plates and concrete and other problems, to achieve the effect of reducing concrete shrinkage cracks and composite structure stress redistribution phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

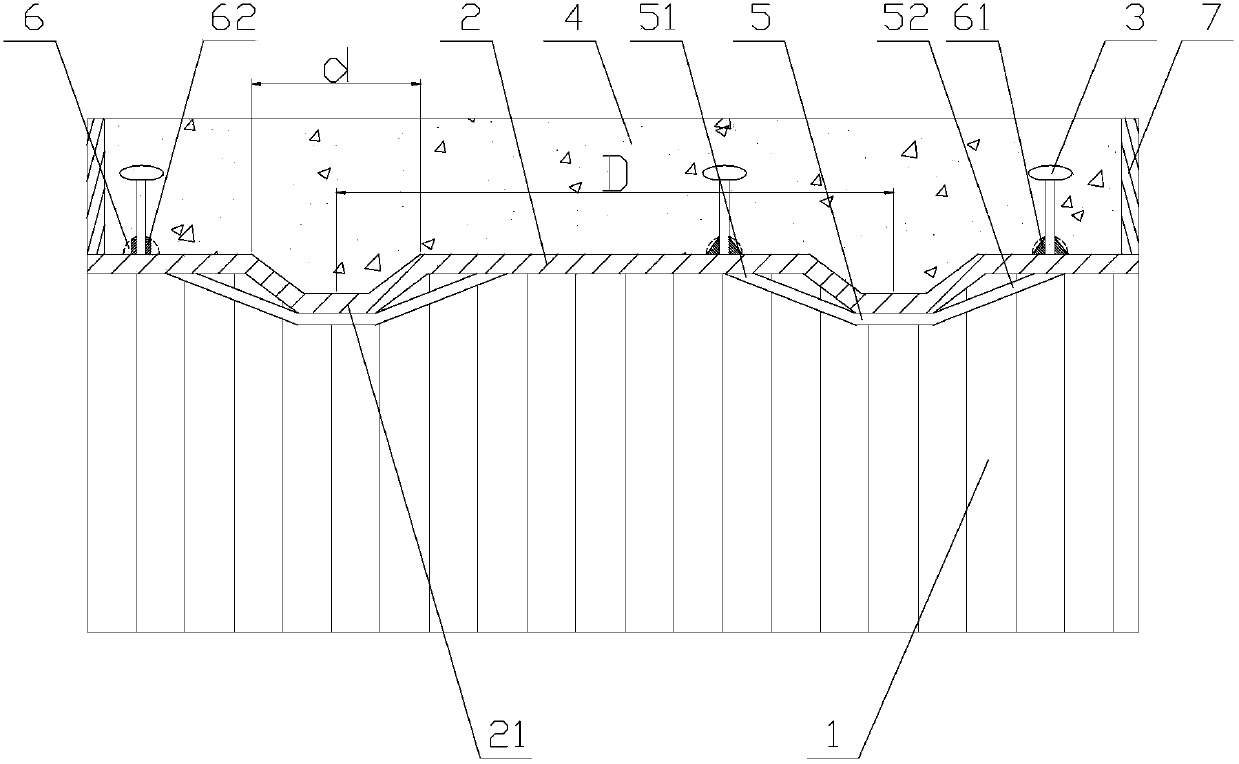

[0022] Combination structure Microwave shrinkage connection structure, such as figure 1 As shown, it includes corrugated steel web 1, flange plate 2, and concrete 4. One side of the flange plate 2 is welded with the corrugated steel web 1, and the other side is combined with concrete 4. The flange plate 2 has micro-strain Wave 21, the roughness of the flange plate 2 is 50-500 μm. Limiting end plates 7 are arranged at both ends of the beam, and by setting micro-shaped strain waves 21 on the flange plate, compared with the straight flange plate in the prior art that cannot shrink longitudinally, the flange with micro-strain wave The plate 2 can shrink together with the concrete in the longitudinal direction, and the corrugated steel plate connected with the flange plate 2 itself has a certain longitudinal shrinkage ability. The whole structure can be coordinatively stressed to achieve a fully combined state.

[0023] The micro-shape strain wave 21 is a micro-strain wave with a...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is:

[0031] The micro-shape strain wave 21 is a micro-strain wave with a convex crest, and the wave height of the micro-strain wave 21 is 12 times the thickness of the flange plate 2; The peak length d of the convex portion of the micro-shape strain wave 21 is 180 mm, and the distance D between the peaks of adjacent micro-shape strain waves 21 is 1500 mm.

[0032] The crest of the micro-shape strain wave 21 of the flange plate 2 is closely attached to the contraction connecting plate 5 . The left end 51 and the right end 52 of the contraction connecting plate 5 are welded to the flange plates 2 on both sides of the micro-shape strain wave 21 . The shrinkage stress of welding is used to shrink the micro-shape strain wave 21, so as to achieve the purpose of co-shrinkage of the flange plate 2 and the concrete. In addition, when the shrinkage connecting plate 5 is welded to the flange plate 2 on both sides of the mi...

Embodiment 3

[0036] The difference between this embodiment and embodiment 1 is:

[0037]The micro-shape strain wave 21 is a micro-strain wave with a convex crest, and the wave height of the micro-strain wave 21 is 18 times the thickness of the flange plate 2; The peak length d of the convex part of the micro-strain wave 21 is 210 mm, and the distance D between the peaks of the adjacent micro-strain waves 21 is 2100 mm.

[0038] The micro-shape strain wave 21 is a micro-strain wave with a convex crest, and the wave height of the micro-strain wave 21 is 3-20 times the thickness of the flange plate 2;

[0039] The crest of the micro-shape strain wave 21 of the flange plate 2 is closely attached to the contraction connecting plate 5 . The left end 51 and the right end 52 of the contraction connecting plate 5 are welded to the flange plates 2 on both sides of the micro-shape strain wave 21 . The shrinkage stress of welding is used to shrink the micro-shape strain wave 21, so as to achieve the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com