Clamping mechanism

A buckle and chuck technology, which is applied in the direction of connection components, mechanical equipment, thin plate connection, etc., can solve the problems of inconvenient assembly and disassembly with screws, and achieve simple and convenient mechanism, small volume, and reduce redundant operation steps of closing and opening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

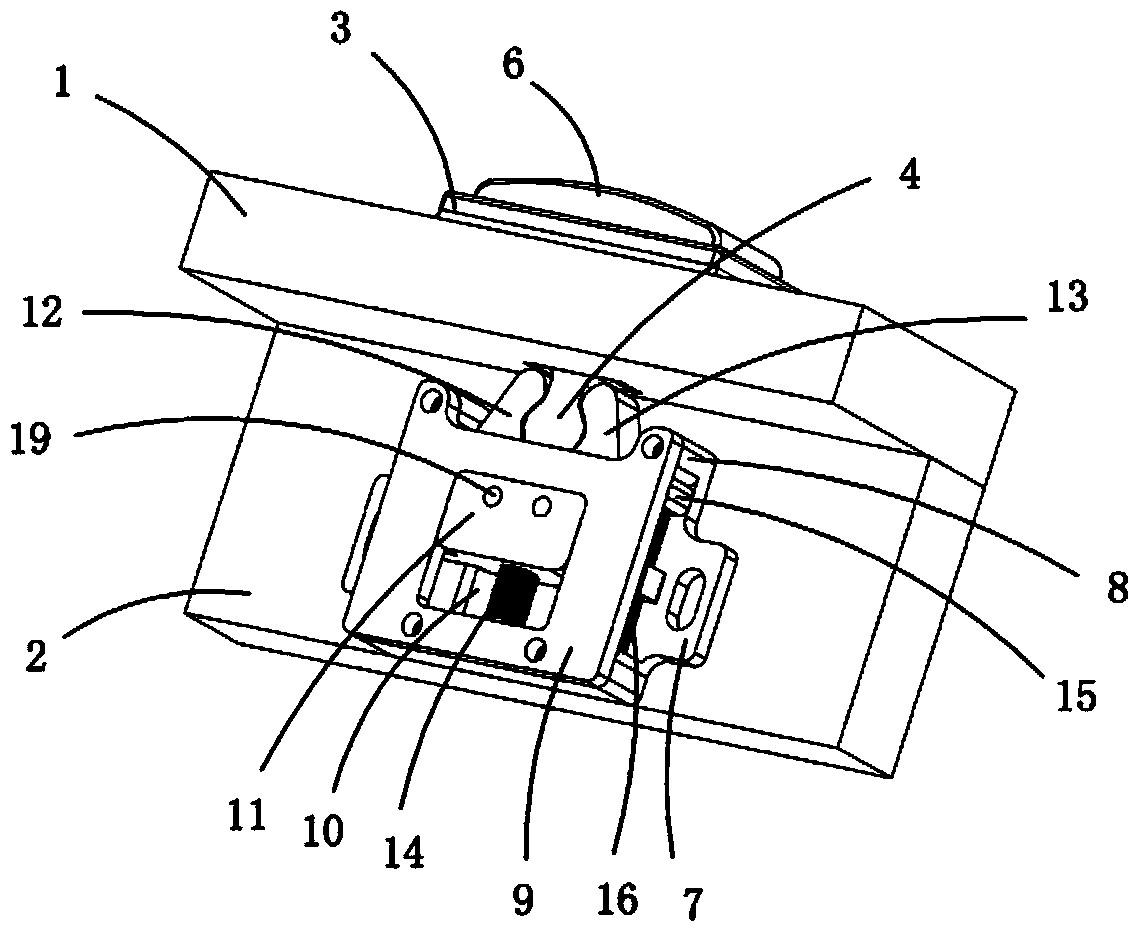

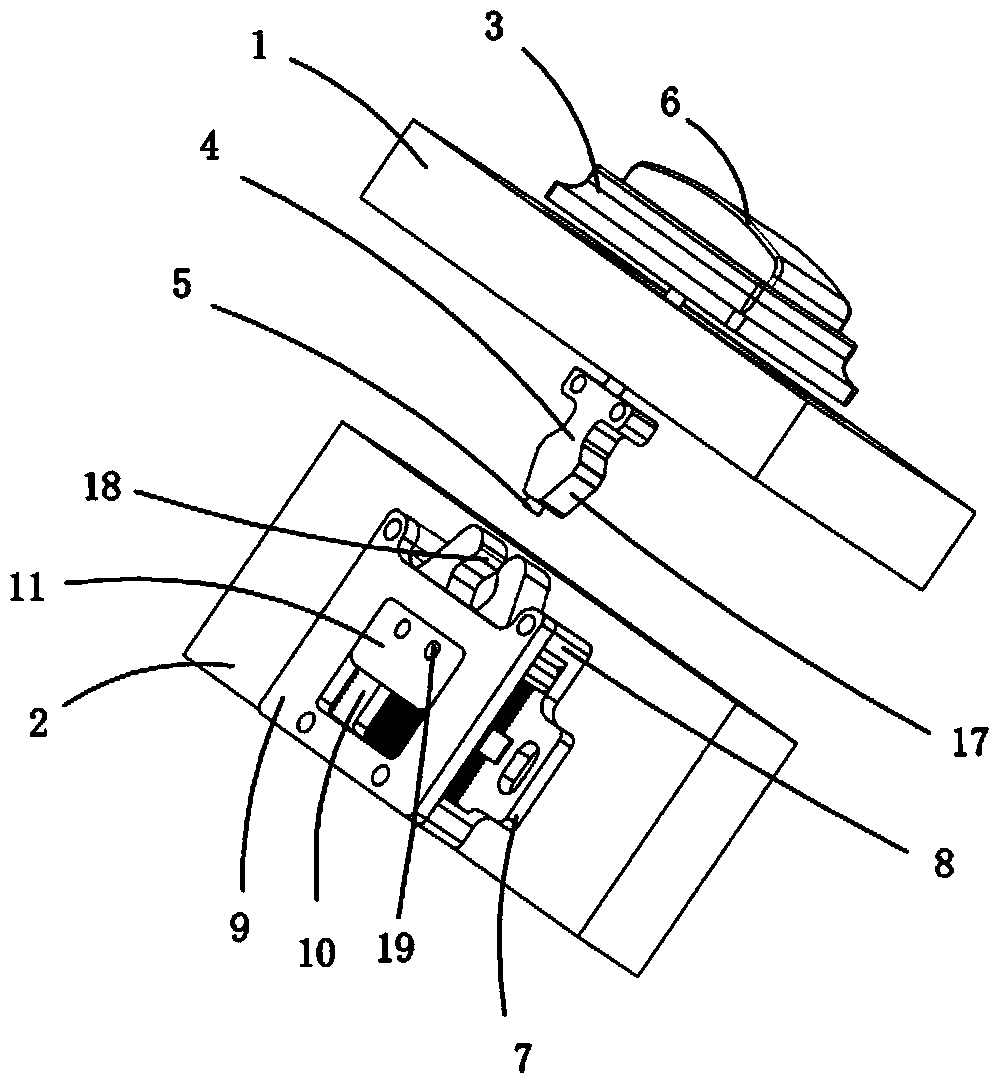

[0018] Examples, see attached figure 1 and 2 , a buckle mechanism, which includes a panel 1 and a side panel 2, the upper side of the panel is fixedly connected to a button seat 3, and the lower side of the panel is fixedly connected to a chuck 4; a guide column is movably connected to the button seat 5 button 6, and the guide post can pass through the chuck.

[0019] A base 7 is fixed on the side plate, a connecting column 8 is respectively arranged on the four feet of the base, a cover plate 9 is fixedly connected on the base, and a cavity 10 is formed between the base and the cover plate; There is a connecting piece 11, the left and right sides of the upper part of the connecting piece are respectively movably connected with the left and right button heads 12 and 13, and the lower part of the connecting piece is connected to the inner side wall of the base through a spring a14; There is a flange 15, and the flange is clamped at the connecting column on the upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com