A pipe diameter self-adaptive claw and pipe diameter self-adaptive underwater fixed-point operation device

A working device and claw technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of limited working range, difficult circular motion of welding devices, limited annular locking force, etc. Improved stability and safety, good and bad drive adaptability, and reduced jaw size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is a detailed description of the present invention with reference to the drawings.

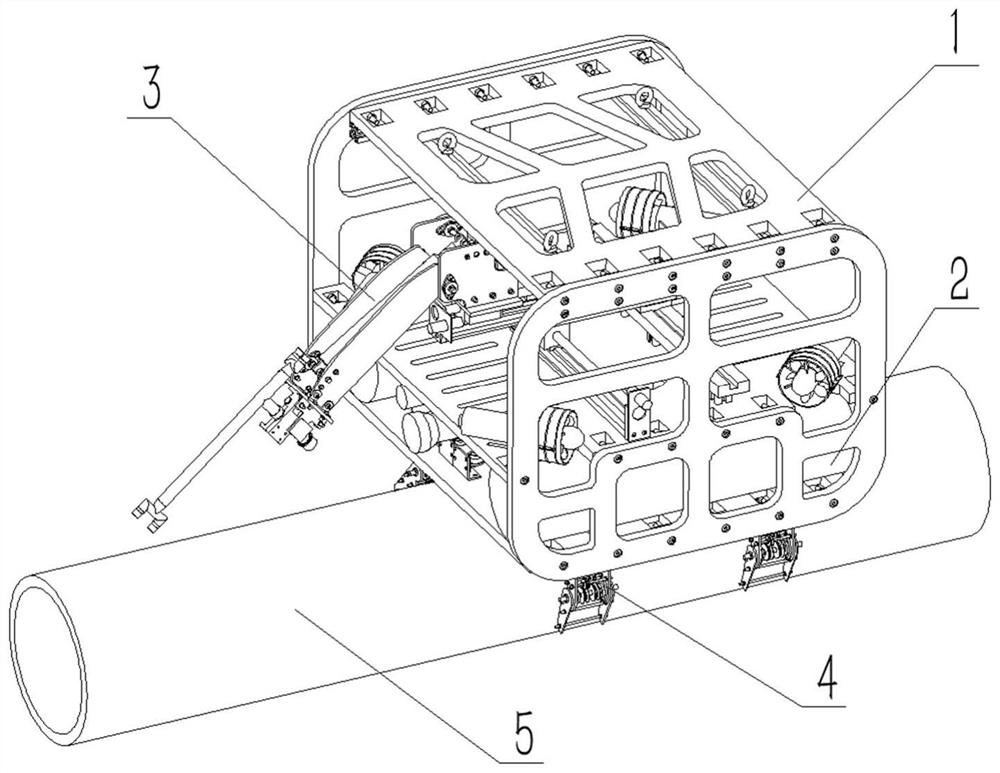

[0045] Such as figure 1 As shown, the pipe diameter adaptive underwater fixed-point operation device of the present invention includes a device body 1, a control mechanism 2, an operating mechanism 3, and a pipe diameter adaptive jaw 4.

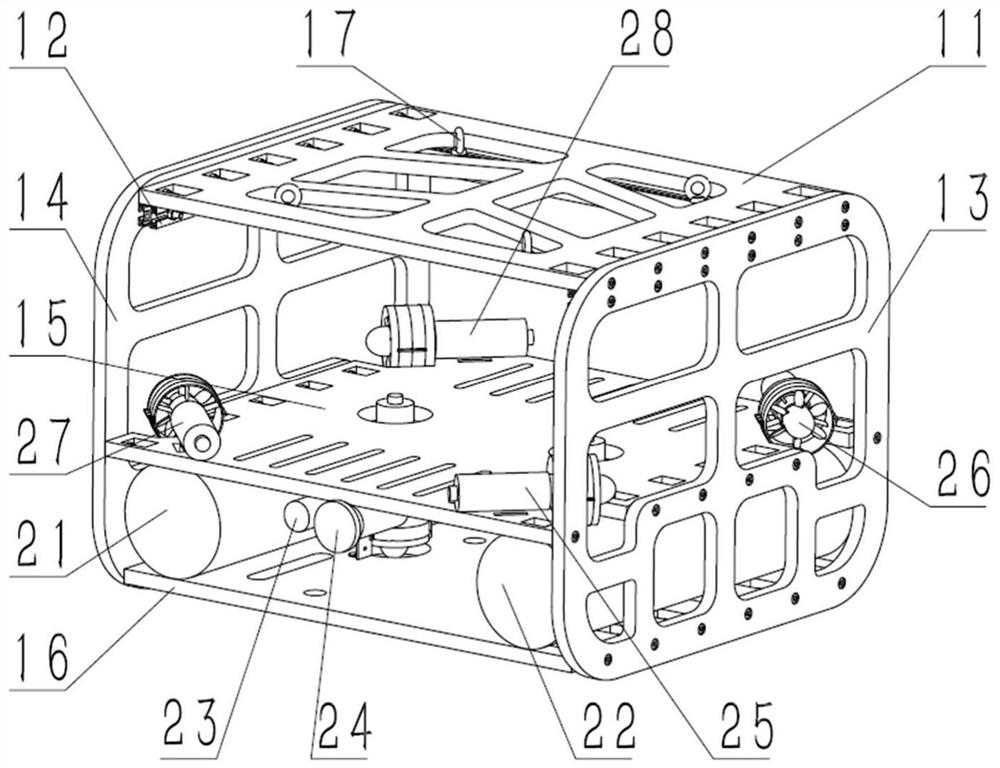

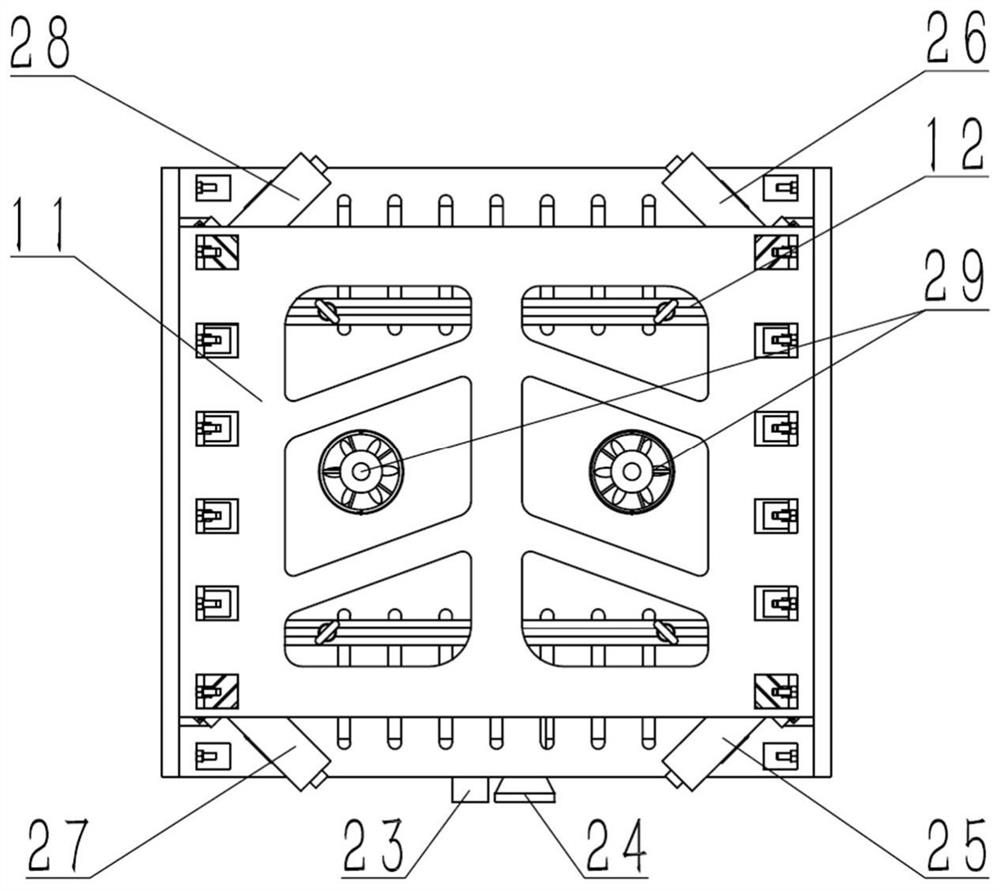

[0046] Such as Figure 2-3 As shown, the main body 1 includes a left side plate 13, a right side plate 14, a top plate 11, a load-bearing material 12, a middle plate 15 and a bottom plate 16. The control mechanism 2 includes an electronic cabin 21, a power cabin 22, a horizontal thruster group (including four horizontal thrusters, namely: left front thruster 25, left rear thruster 26, right front thruster 27, right rear thruster 28), vertical Propeller group, camera 23 and lighting 24. The electronic cabin 21 is used to control the power cabin 22 under the control of the background computer control system to drive the horizontal thruster grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com