Spontaneous breathing type airbag sole

A self-breathing and airbag technology, which is applied to soles, footwear, applications, etc., can solve the problems of affecting air flow, shortening life, and inconvenient mass production, and achieves the effect of increasing air circulation, low cost, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

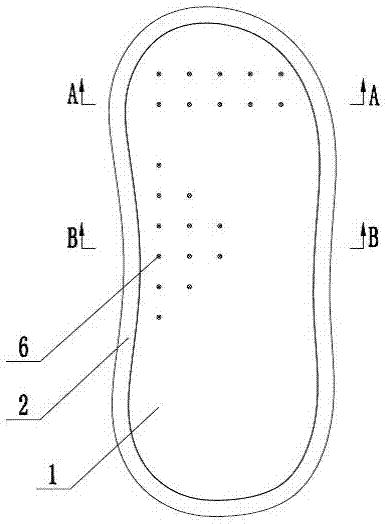

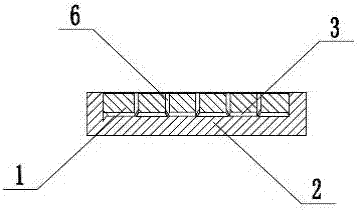

[0024] Example: such as figure 1 As shown, a self-breathing airbag sole includes an outer sole 2 with an open upper end that is a boat-shaped structure, and an inner sole 1 accommodated in the outer sole 2, wherein the inner sole 1 and the outer sole 2 are stacked up and down. They are combined but can be separated from each other as independent bodies. The outer sole 2 has a circle of flanging extending from the periphery of the inner sole 1 so as to better combine with the shoe body and facilitate gluing.

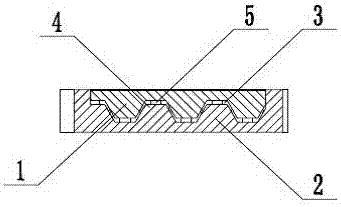

[0025] Between the inner sole 1 and the outer sole 2, there is an interlayer cavity 3 arranged at intervals, and the interlayer cavity 3 is formed by a plurality of pairs of bosses 4 that are respectively arranged on the two opposing cavity walls and push to the respective opposite side cavity walls. The bosses 4 on the walls of the two chambers of the interlayer cavity 3 all have a terraced structure with a wide base and a narrow top. The bosses 4 on the two chamber wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com