Inkjet printing method of ultra-thin thin fabric and inkjet printing combination layer thereof

An inkjet printing and fabric technology, applied in the field of textile printing and dyeing, can solve the problems of low authenticity rate, high cost of inkjet printing, difficulty of inkjet printing on ultra-thin fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Mix 5 kg of printing paste sodium alginate, 10 kg of urea, and 2 kg of baking soda evenly, stir in 83 kg of water, and dissolve it into ink-absorbing layer slurry; / square meter) several, the fabric is immersed in the above slurry, and then the excess slurry is rolled off with a rolling car, and dried.

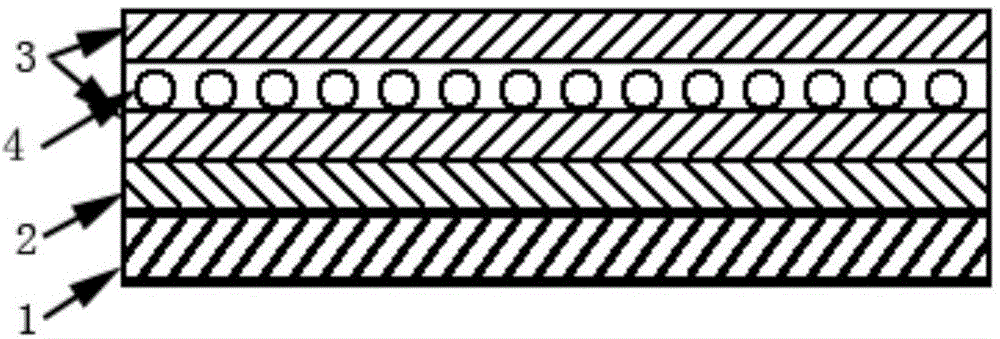

[0058] Then take some 100 g / m2 paper, apply polypropylene pressure-sensitive adhesive, and dry; bond the above-mentioned silk fabric with the paper, pass through a rolling machine, so that the silk fabric and the paper are bonded together, and rolled to be used, to be figure 1 structure shown.

[0059] Will figure 1 The combination of the ink-jet ink-absorbing layer, silk foreign spinning, ink-jet ink-absorbing layer, adhesive layer and carrier layer of the structure shown is put on the Japanese MIMAKI TS-34 digital printing machine, and the reactive dye ink-jet ink is used for ink-jet printing. The ink-absorbing layer fixes the ink, and the carrier layer prevents t...

Embodiment 2

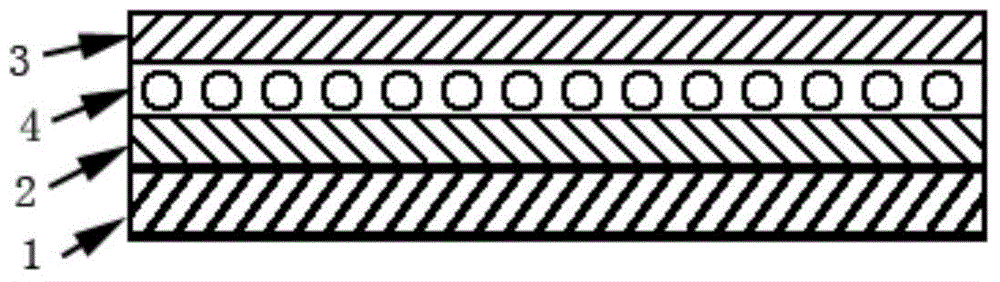

[0061] Mix 10 kg of sodium carboxymethyl starch in the etherified starch of the printing paste, 2 kg of urea, and 2 kg of ammonium sulfate evenly, put them into 86 kg of water and stir, and dissolve into ink absorbing layer slurry; take 400T, 15D A number of nylon fabrics (35 grams per square meter) are used, and the above slurry is scraped and coated on the surface of nylon fabric with a scraper, and dried.

[0062] Then take a number of polyester films with a thickness of 20 microns, apply polyester thermoplastic resin solution, and dry; the above-mentioned nylon yarn is bonded to the polyester film, and is rolled and heated to make the nylon yarn and the polyester film adhere to each other. put together, and rolled up for use, to become figure 2 structure shown.

[0063] Will figure 2 The combination of ink-jet ink-absorbing layer, nylon spinning, adhesive layer, and carrier layer of the structure shown is put on the Japanese Muto 1638 digital printing machine, and acid...

Embodiment 3

[0065] Put 3 kilograms of sodium carboxymethyl cellulose into 97 kilograms of water and stir to dissolve into ink absorbing layer slurry; take some ultra-thin polyester screen cloth (20 grams per square meter), and put the polyester screen cloth Immerse in the above slurry, then roll off the excess slurry with a rolling car, and dry it for later use.

[0066] Take a number of biaxially stretched polypropylene films with a thickness of 40 microns, apply the mixed two-component polyurethane adhesive to the surface of the polypropylene film with a gravure printing machine, and dry it. The printing surface of the film is pasted, pressurized, and matured for several hours, and it is ready figure 1 Inkjet printing combined layers of ultra-thin fabrics shown.

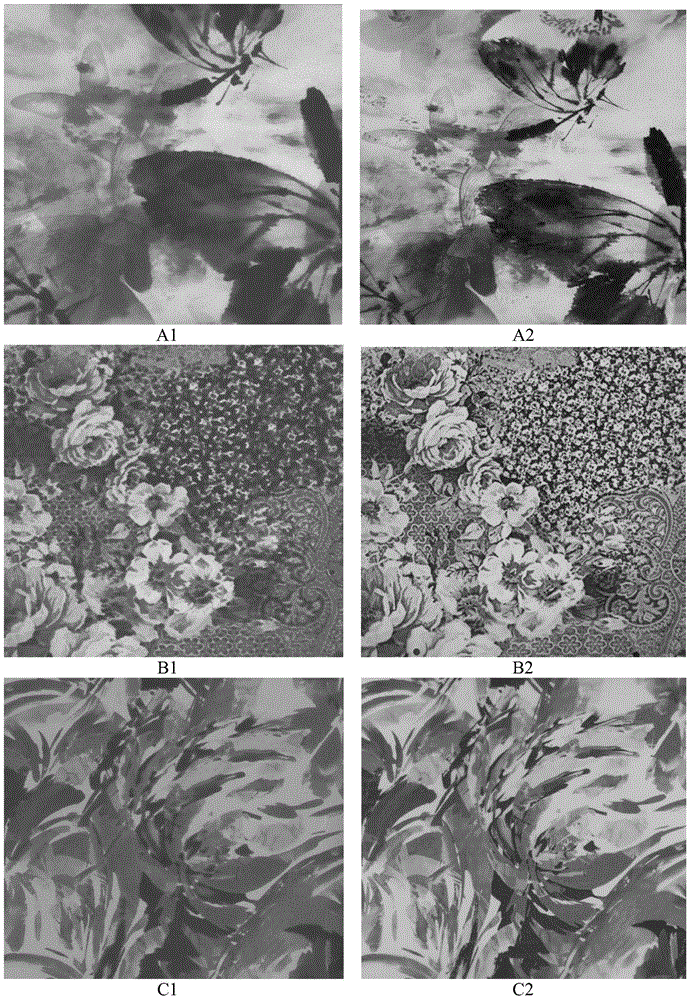

[0067] Roll the above combination layer, install it on the Italian MS-JPK inkjet printing machine, select the disperse dye inkjet printing ink, spray-paint the flower pattern on the above combination, then enter the oven to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com