Printer having skewed transfix roller to reduce torque disturbances

A technology of printers and fixing rollers, which is applied in printing machines, printing devices, printing, etc., and can solve problems such as low image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

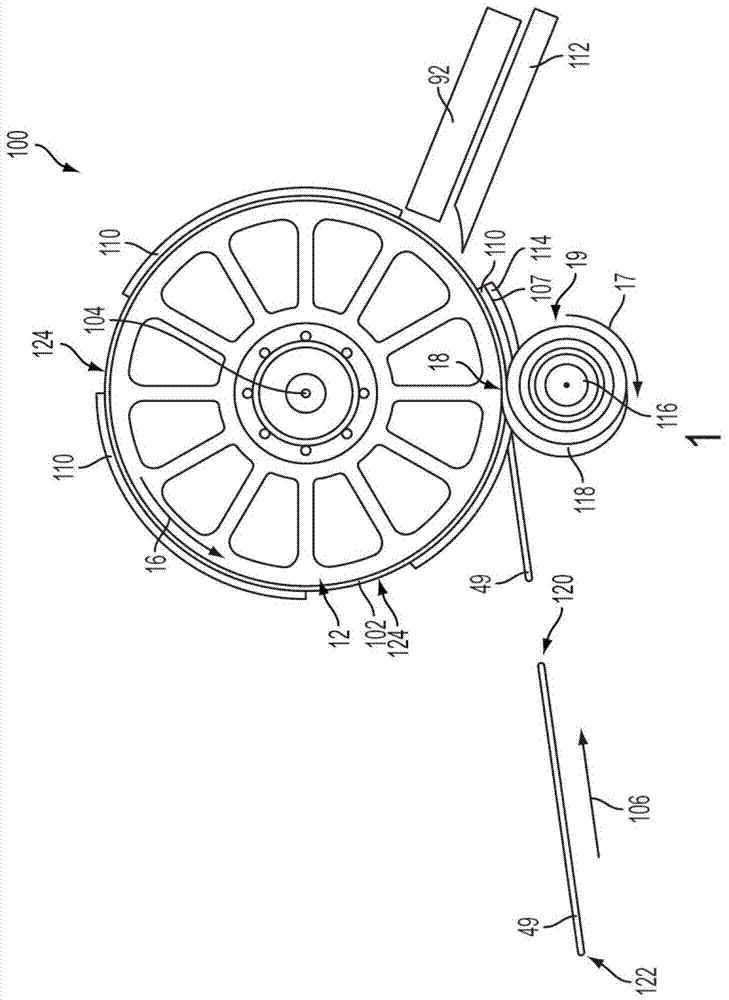

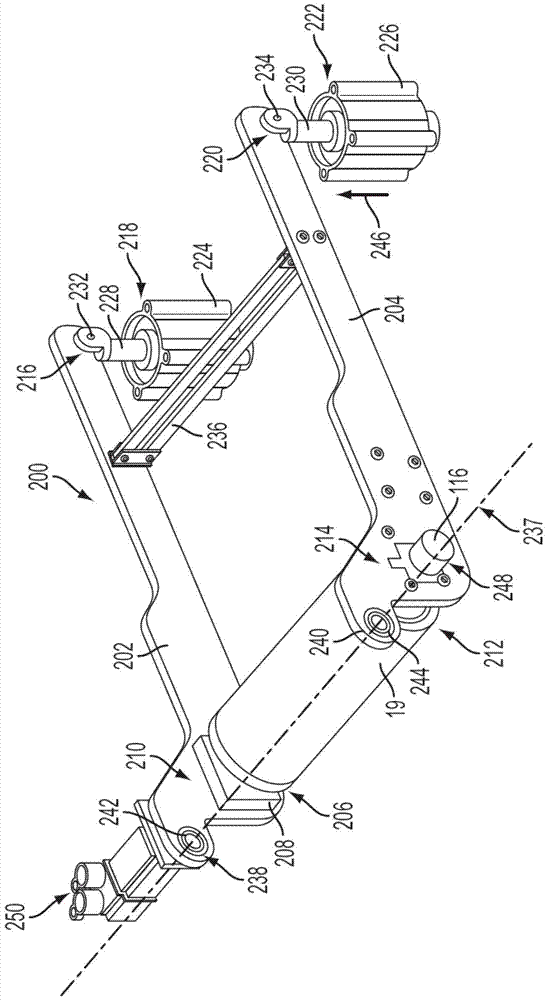

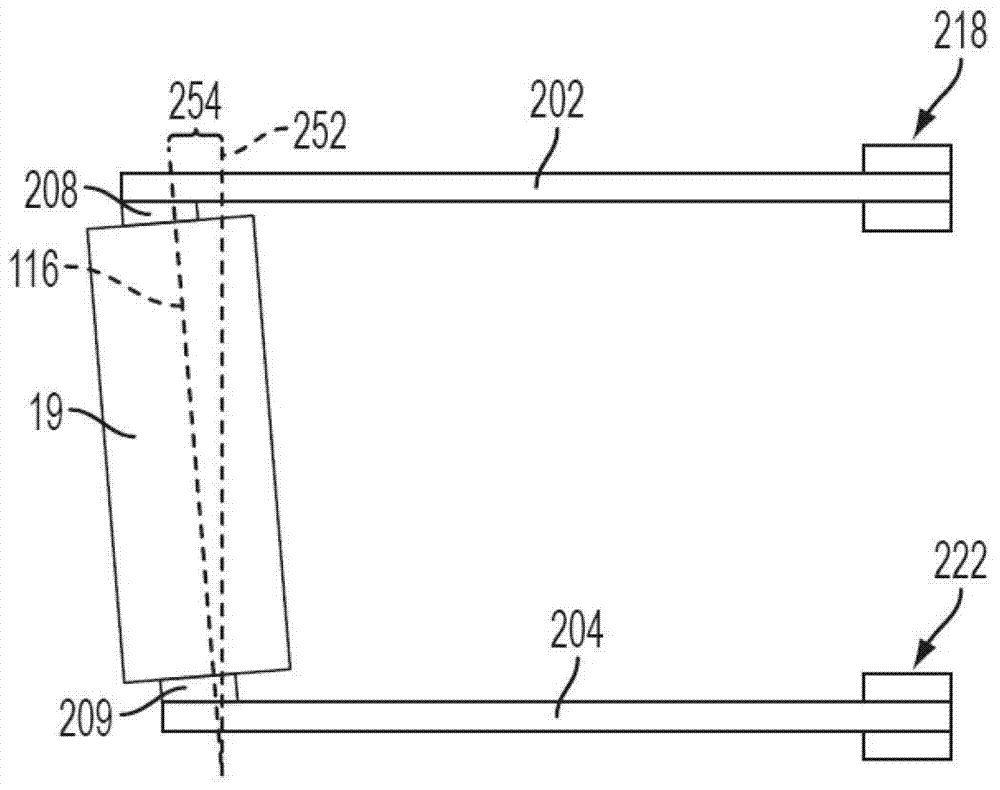

[0017] Figure 5 A high speed phase change ink image producing machine or printer 10 is shown. As shown, printer 10 includes a frame 11 that directly or indirectly supports operating subsystems and components, as described below. The printer 10 includes an image receiving member 12, which is shown in the form of a drum, but may also include a supporting endless belt. The image receiving member 12 has an imaging surface 14 movable in a direction 16 and on which a phase change ink image is formed. A transfix roller 19 , rotatable in direction 17 , is loaded against surface 14 of drum 12 to form a transfix nip 18 in which the ink image formed on surface 14 is transferred to a recording medium 49 .

[0018] The high speed phase change ink printer 10 also includes a phase change ink delivery subsystem 20 having at least one source 22 of one color phase change ink in solid form. Because the phase change ink printer 10 is a multicolor image producing machine, the ink delivery syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com