Electroplating barrel screen

A technology of roller mesh and screen plate, which is applied in the electrolysis process and electrolysis components, etc., can solve the problem that parts are easy to slide along the inner wall of the roller, and achieve the effect of improving the quality of barrel plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

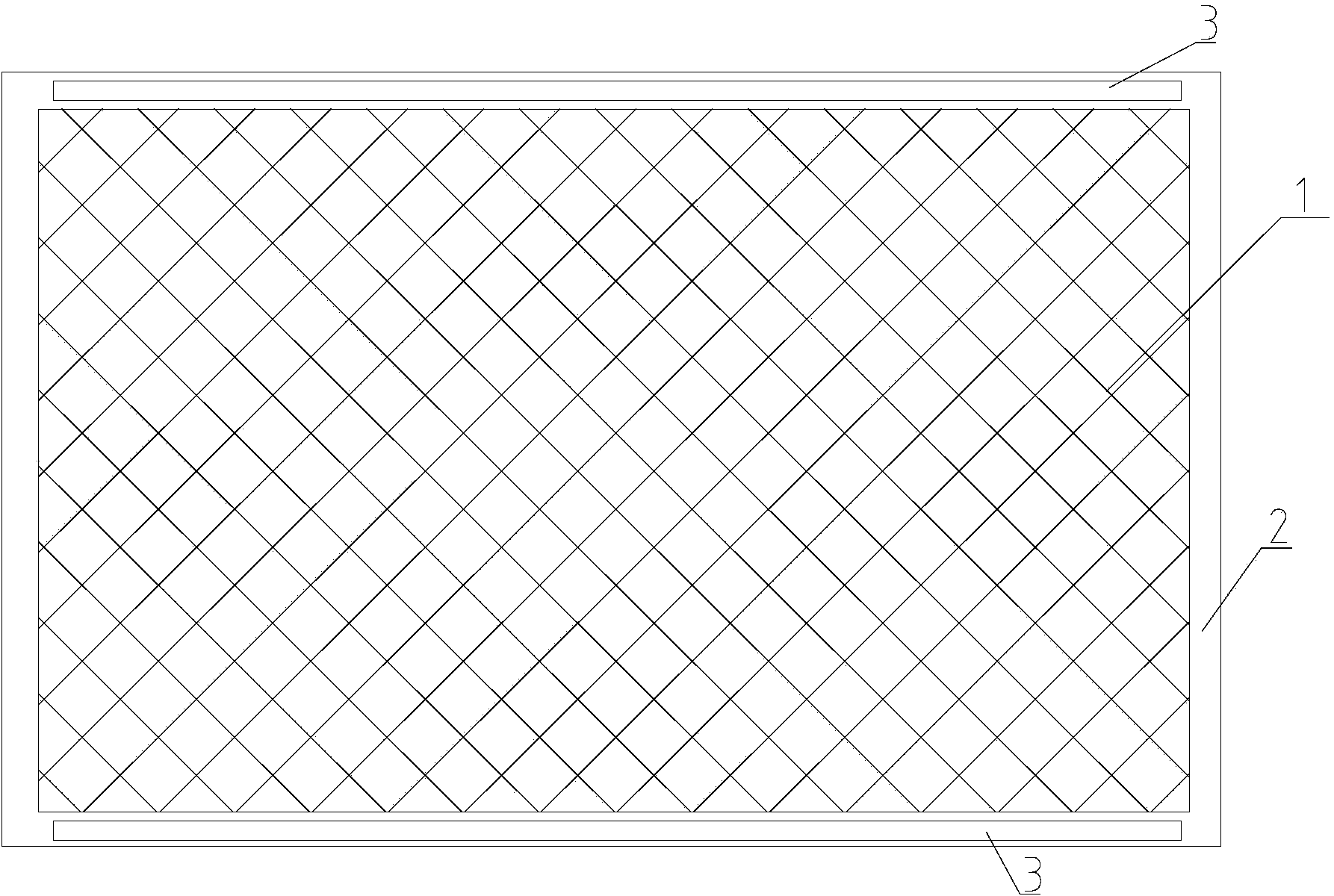

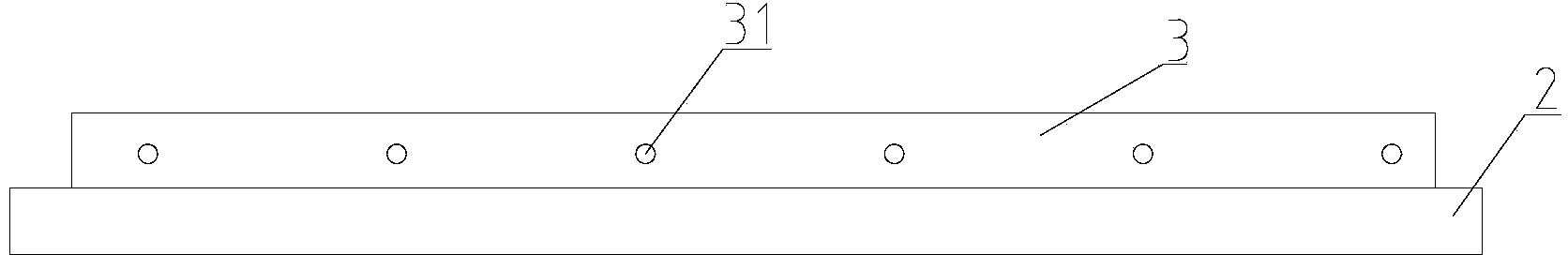

[0023] Below in conjunction with the accompanying drawings, the electroplating drum screen plate of the present invention will be further described. Such as figure 1 , figure 2 As shown, the electroplating drum screen includes a frame 2 and a screen 1 arranged in the frame 2. The screen 1 is made by injection molding of polypropylene, and the screen 1 is made by injection molding of polypropylene. It has a higher opening rate and improves the electroplating quality of the parts. The mesh plate 1 is welded on the frame 2, that is, the mesh plate 1 and the frame 2 are both made of polypropylene material, and the welding method adopts hot air Welding, melting the edge of the screen 1 and the frame 2 by heating, and then connecting the frame 2 and the screen 1, the screen 1 and the frame 2 are fused together after solidification, and the welding of the screen 1 and the frame 2 is realized. The frame 2 is provided with a baffle 3 for preventing parts from sliding along the inner...

Embodiment 2

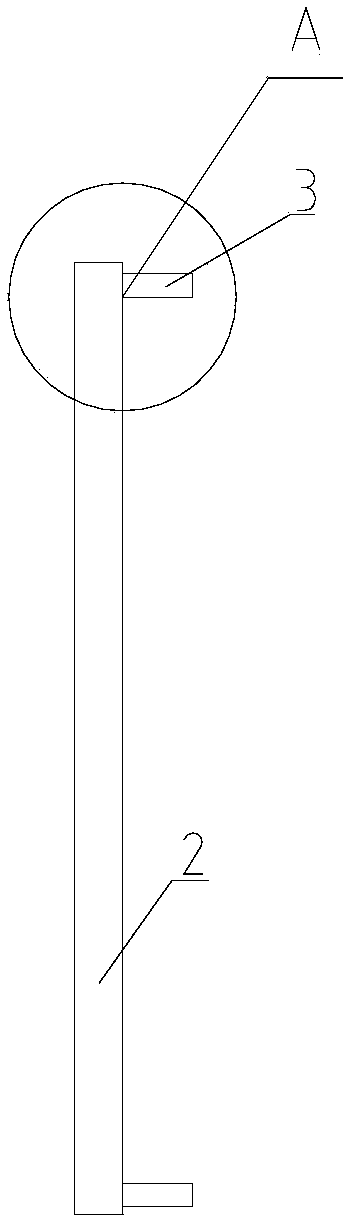

[0027] Such as Figure 5 , Image 6 As shown, there are at least two baffles 3 on the same frame 2, the cross-sectional shape and longitudinal section shape of the baffles 3 are arc-shaped, and the baffles 3 are evenly distributed on the frame 2, that is, the The baffle 3 is a curved space structure similar to a propeller, and there is a gap between the baffles 3 on the same frame 2. This structure makes it easier for the parts accumulated at the contact between the baffle 3 and the frame 2 to be removed from the baffle 3. Sliding out, and because the baffle plate 3 is arc-shaped, the part produces an overturning effect after sliding out, so that the electroplating quality of the part is better, and the electroplating quality of the part is improved.

[0028] During the use of the above technical solution, by setting the baffle plate 3 on the frame 2, the parts sliding along the inner wall of the drum will accumulate on the baffle plate 3, and when the baffle plate 3 rolls to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com