A method for measuring the effect of bolt slippage on the bearing capacity of steel structures

A steel structure bearing and bolt slippage technology, which is applied in the direction of instruments, calculations, and electrical digital data processing, can solve the problem that there is no effective method for simulating bolt slippage, so as to enhance calculation convergence, ensure calculation accuracy, and improve calculation accuracy. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

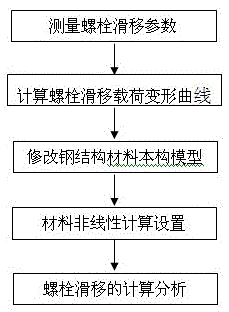

[0021] Such as figure 2 Shown, the inventive method comprises the following steps:

[0022] The first step is to test the bolt slippage parameters;

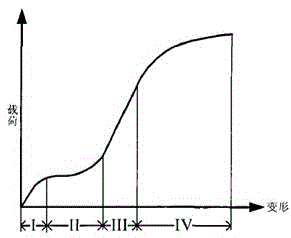

[0023] According to the connection type of the bolt, the slip load, gap slippage, yield load and deformation corresponding to the yield load of the bolt are tested.

[0024] The second step is to calculate the bolt slip load deformation curve;

[0025] Substitute the above parameters into the load-deformation function of deformation slip and the load-deformation function of gap slip respectively to calculate the load-deformation curve.

[0026] The third step is to modify the constitutive model of steel structure materials;

[0027] According to the calculated bolt slip load deformation curve, combined with the material properties of the bolted steel structure, the material constitutive model is corrected.

[0028] The fourth step is the material nonlinear calculation setting;

[0029] In the finite element calculation soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com