Bicycle wheel and relative manufacturing process

A bicycle and wheel hub technology, applied in the field of spoke wheels, can solve problems such as lack of structural functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

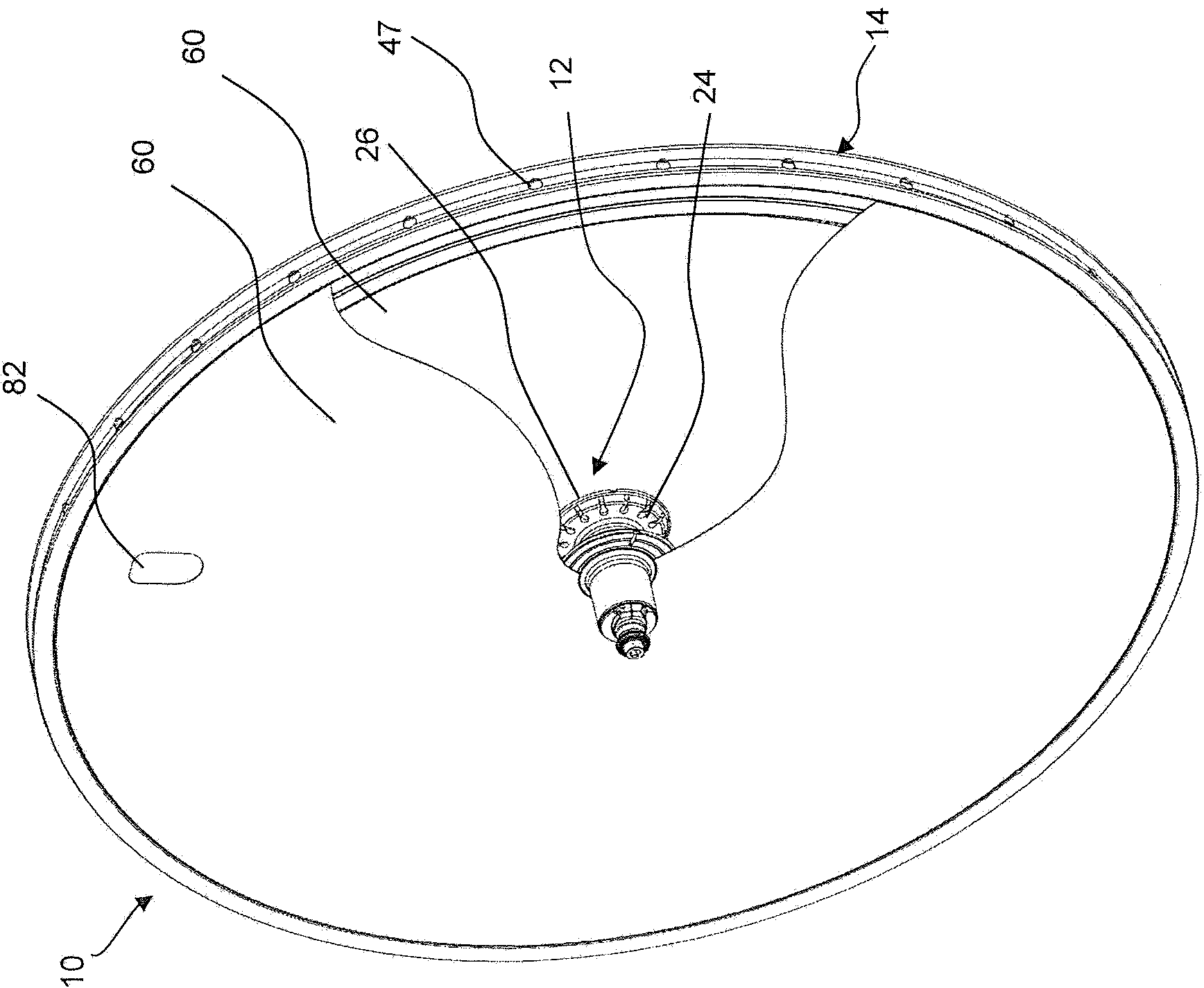

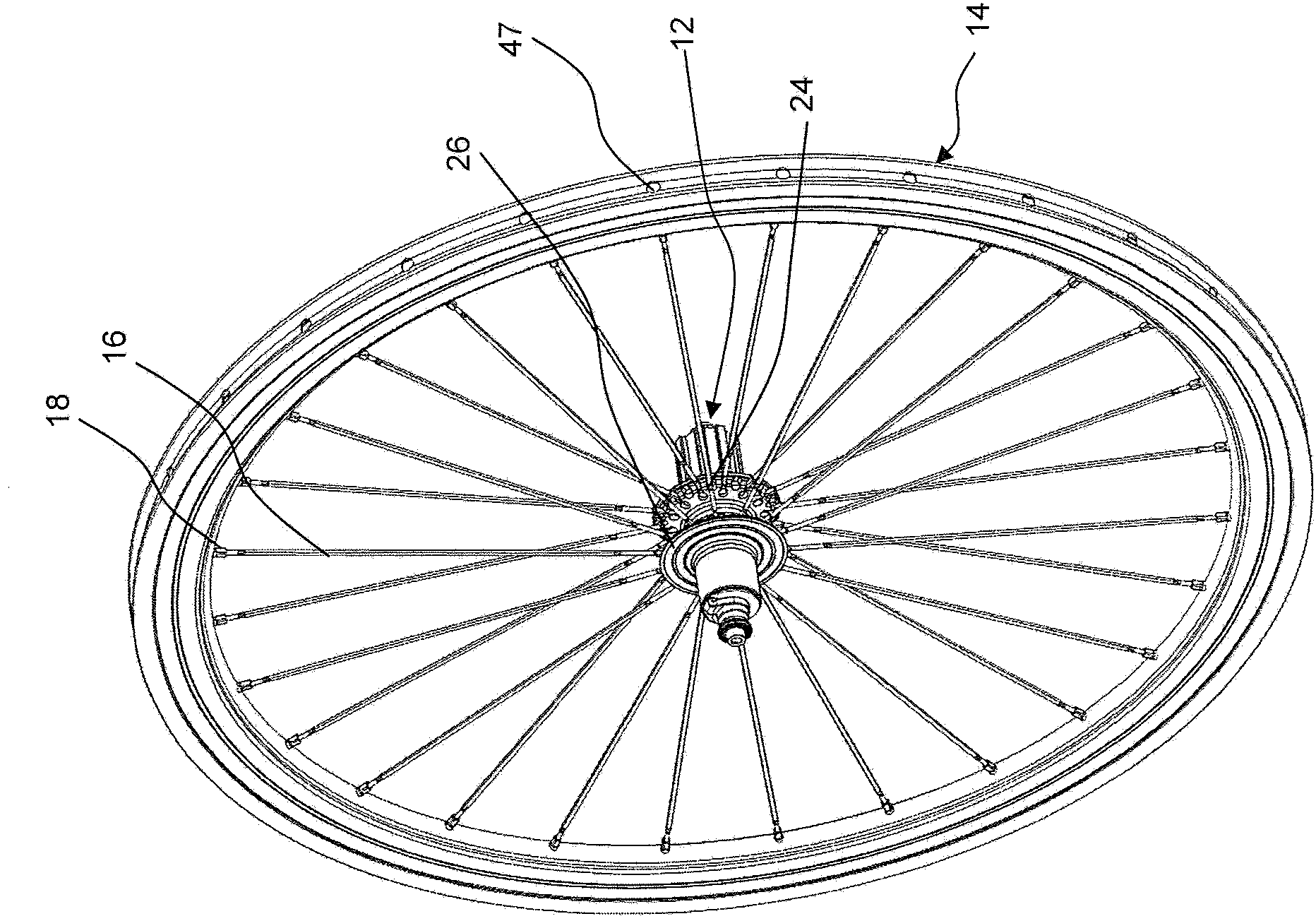

[0047] refer to Figure 1-14 , discloses a disc wheel or double-sided cam 10 according to an embodiment of the present invention ( figure 1 ) method of manufacture.

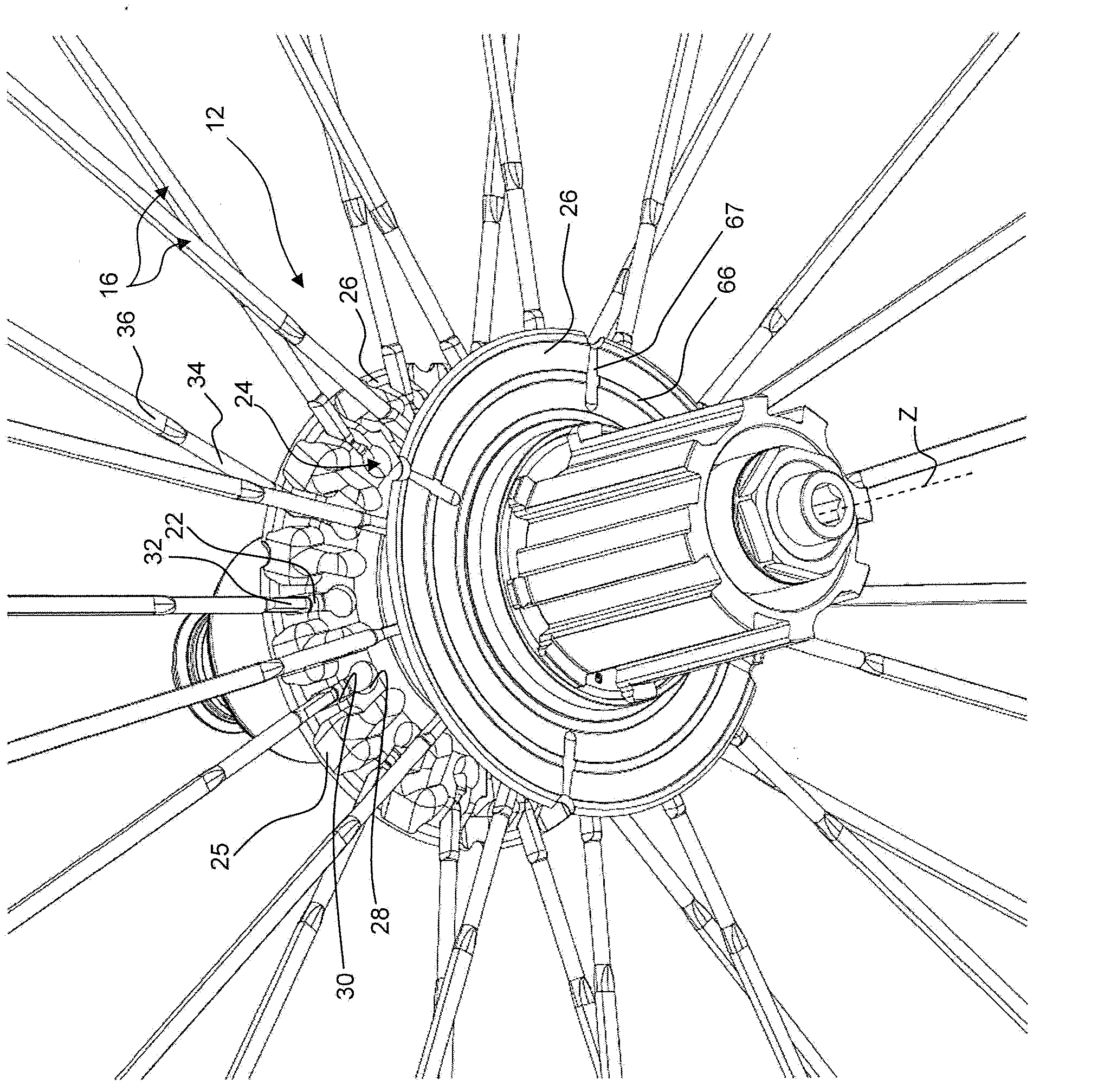

[0048] Initially, a hub 12, a rim 14, a plurality of spokes 16, and a corresponding plurality of nipples 18 and possibly centering washers 20 are provided ( figure 2 , 7 ). The spokes 16 extend between the hub 12 and the rim 14 and are fixed, except as expressly stated below, by means of a nipple 18 and possibly a centering washer 20 , respectively, in a manner analogous to the case of manufacturing a spoked wheel. Spokes 16, nipples 18 and washers 20 form tensioning elements.

[0049] in more detail and refer to Figure 2-6 , in the embodiment shown therein, each spoke 16 is straight, ie extends along a rectilinear direction X or longitudinal axis X coincident with its tensioning direction, and at the end associated with the hub 12, the spoke 16 has a head 22 protruding perpendicularly to the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com