Handle locking structure and electronic equipment possessing the handle locking structure

A locking structure and handle technology, applied to the circuit layout of the support structure, electrical equipment shell/cabinet/drawer, wing leaf handle, etc., can solve the problems of inconvenient use and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The handle locking structure provided by the embodiment of the present invention can be applied to electronic devices such as servers and communication devices. The electronic equipment may include a rack and a case, and the case is arranged on the rack.

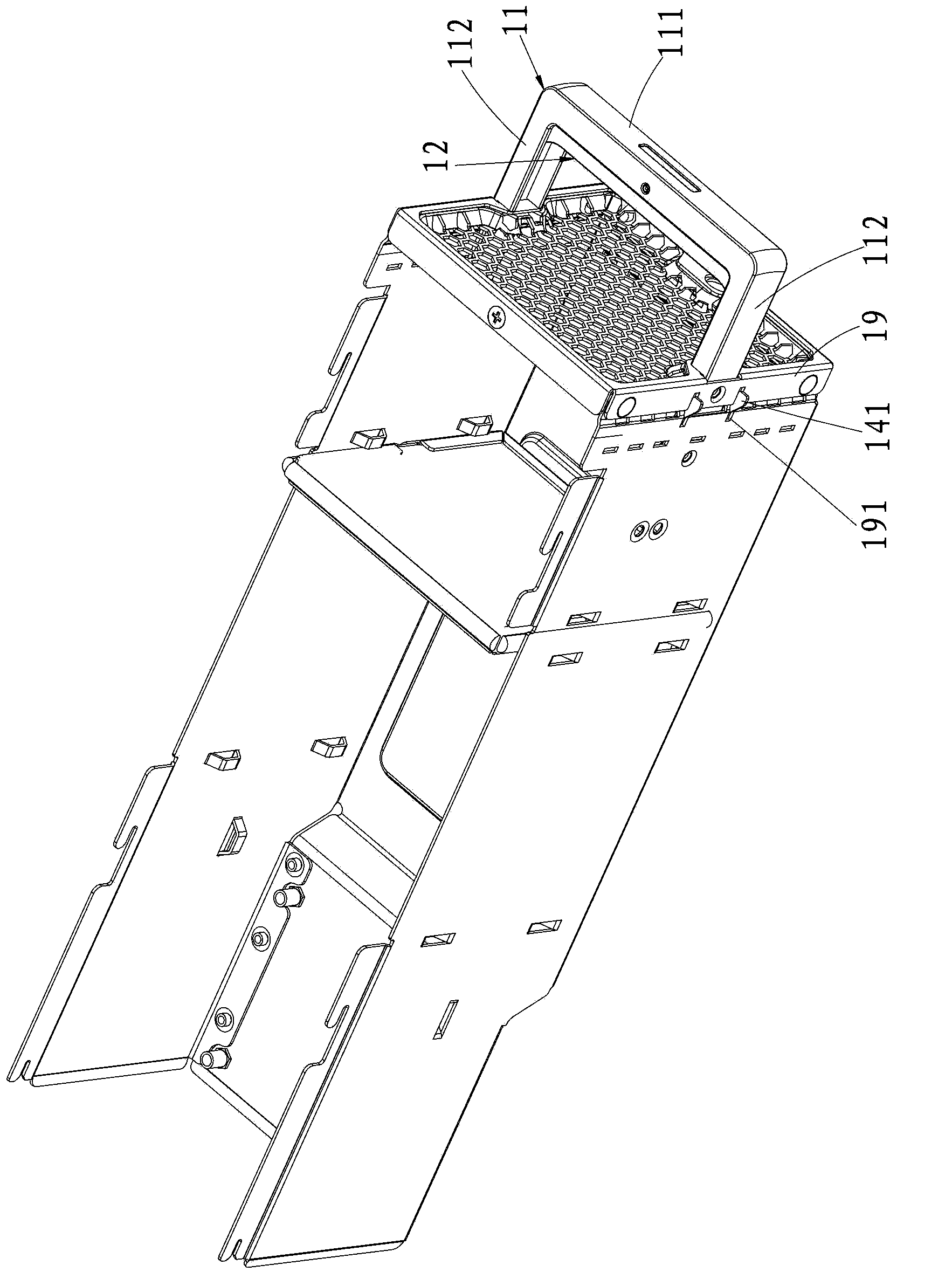

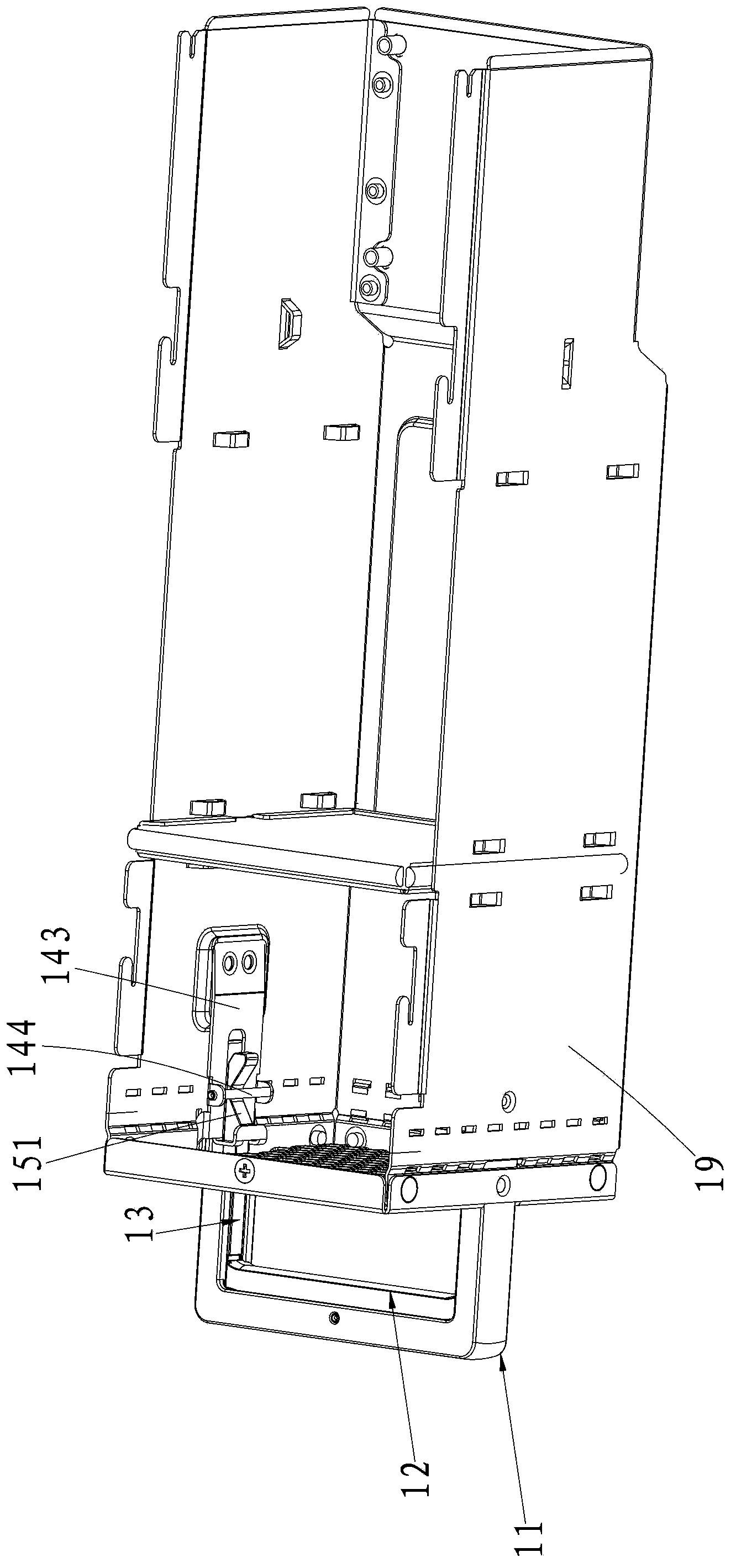

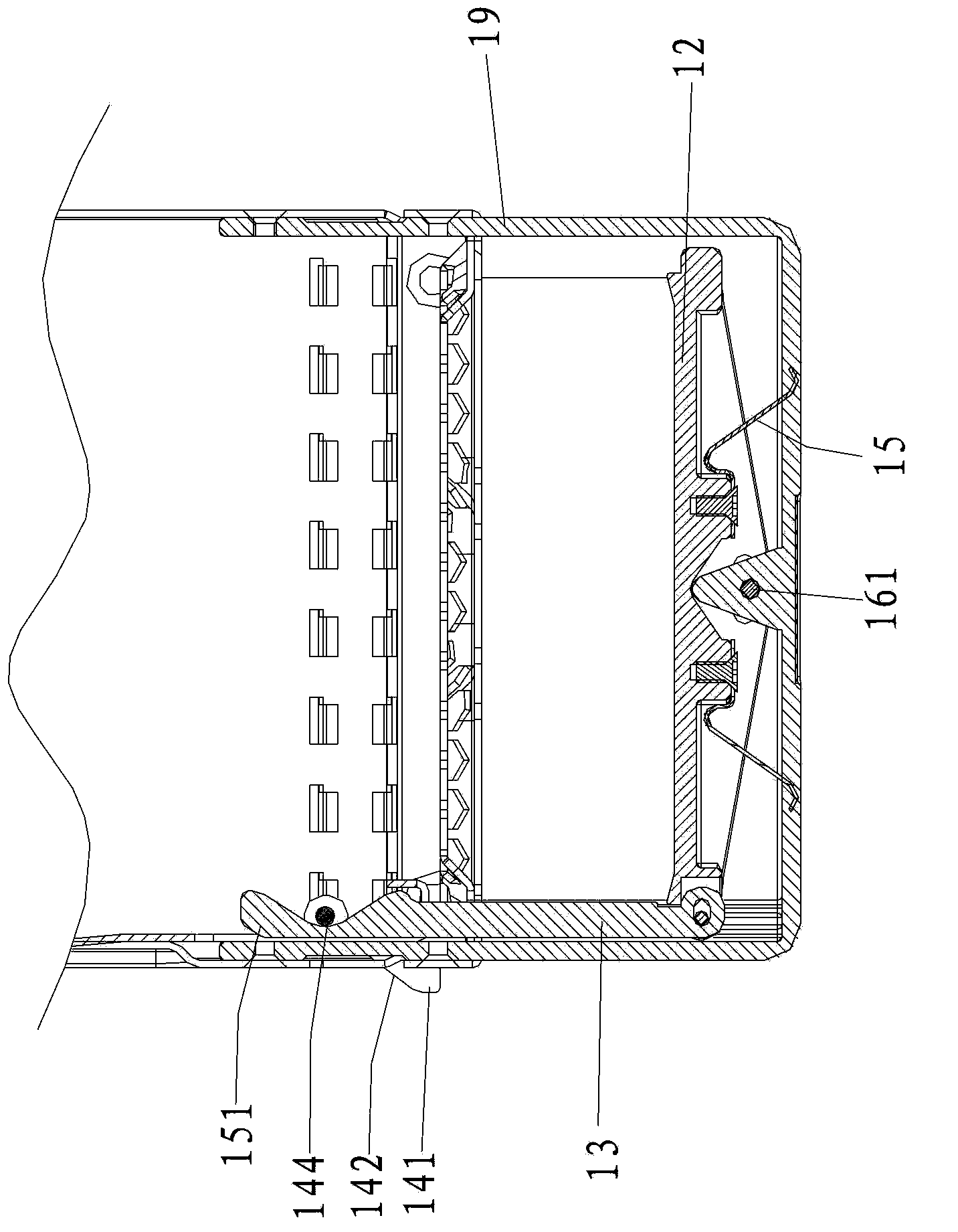

[0022] Such as figure 1 and figure 2 As shown, the above-mentioned handle locking structure includes a handle body 11 , a pressing member 12 , a transmission member 13 connected to the pressing member 12 , and a locking part that can be driven by the transmission member 13 .

[0023] Among them, such as figure 1 and figure 2 As shown, the handle body 11 can be fixedly connected to the casing 19 of the case, and the operator can hold the handle body 11 to facilitate inserting the case into the rack or pulling the case out from the rack. The pressing member 12 is slidably or rotatably connected to the handle body 11. The operator can easily press the pressing member 12 while holding the handle body 11. It can be o...

Embodiment 2

[0040] The handle locking structure provided by the embodiment of the present invention can be applied to electronic devices such as servers and communication devices. The electronic equipment may include a rack and a case, and the case is arranged on the rack.

[0041] Such as Figure 7 and Figure 8 As shown, the above-mentioned handle locking structure includes a handle body 21 , a pressing member 22 , a transmission member 23 connected to the pressing member 22 , and a locking component that can be driven by the transmission member 23 .

[0042] Among them, such as Figure 7 and Figure 8 As shown, the handle body 21 can be connected to the casing of the case, and the operator can hold the handle body 21 to insert the case into the rack or pull the case out from the rack. The pressing member 22 is slidably or rotatably connected to the handle body 21 , and the operator can press the pressing member 22 while holding the handle body 21 , which can be operated with one ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com