Multi-stamp stamping machine with movement capable of vertically rotating in reciprocating mode to change positions

A reciprocating and stamping machine technology, applied in printing, stamping and other directions, can solve the problems of large horizontal space and poor safety, and achieve the effect of reducing horizontal space occupation and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

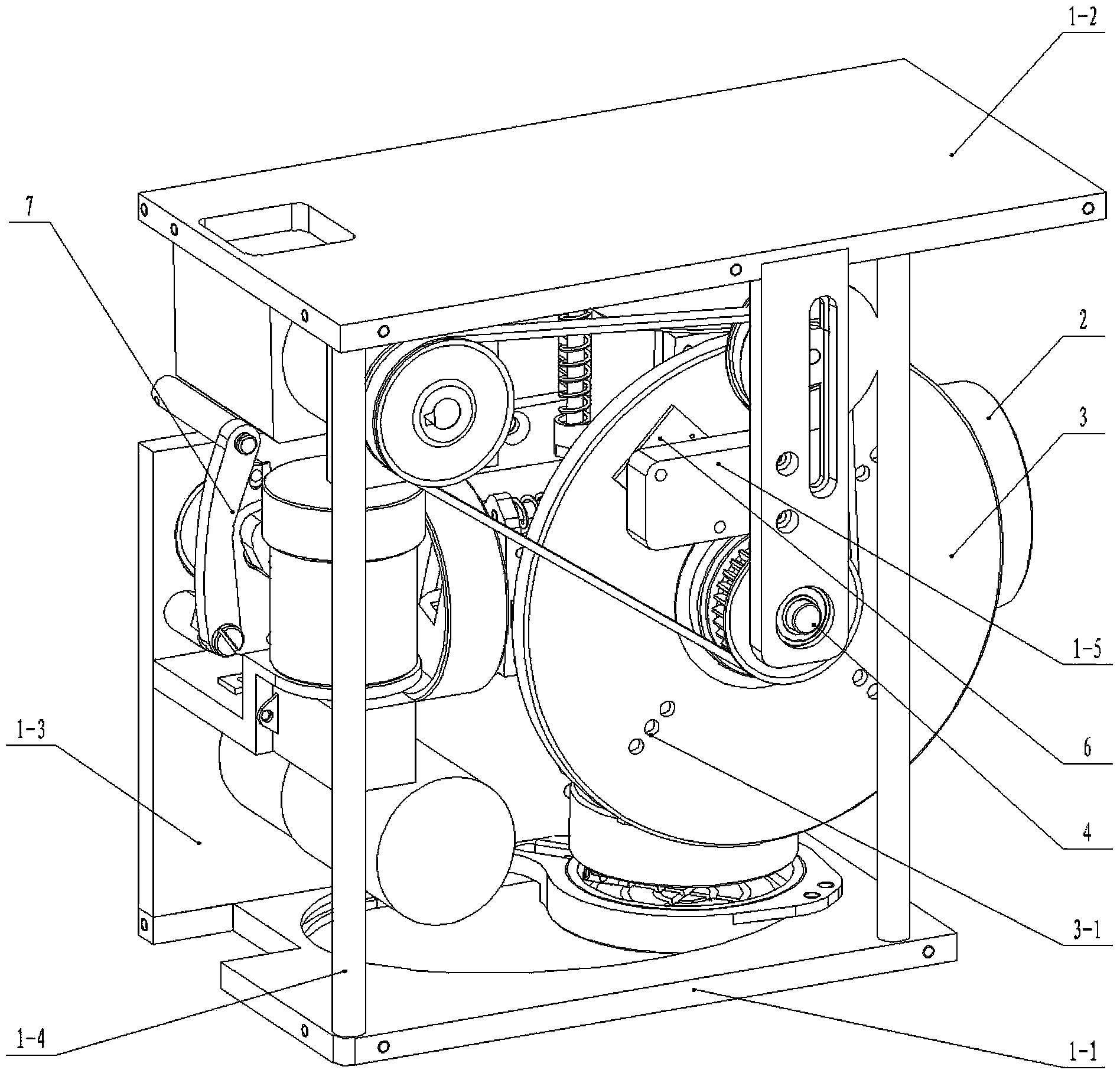

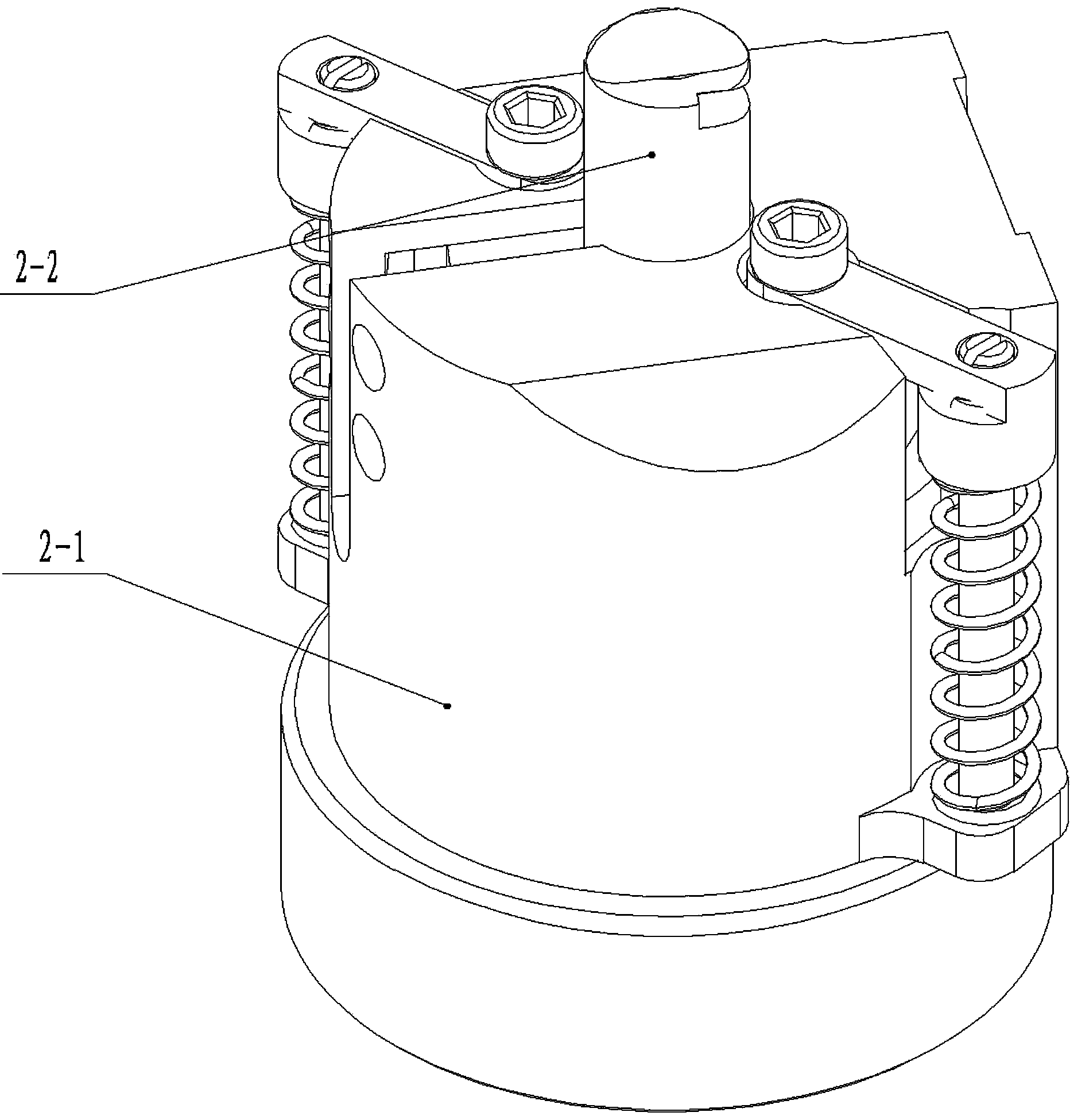

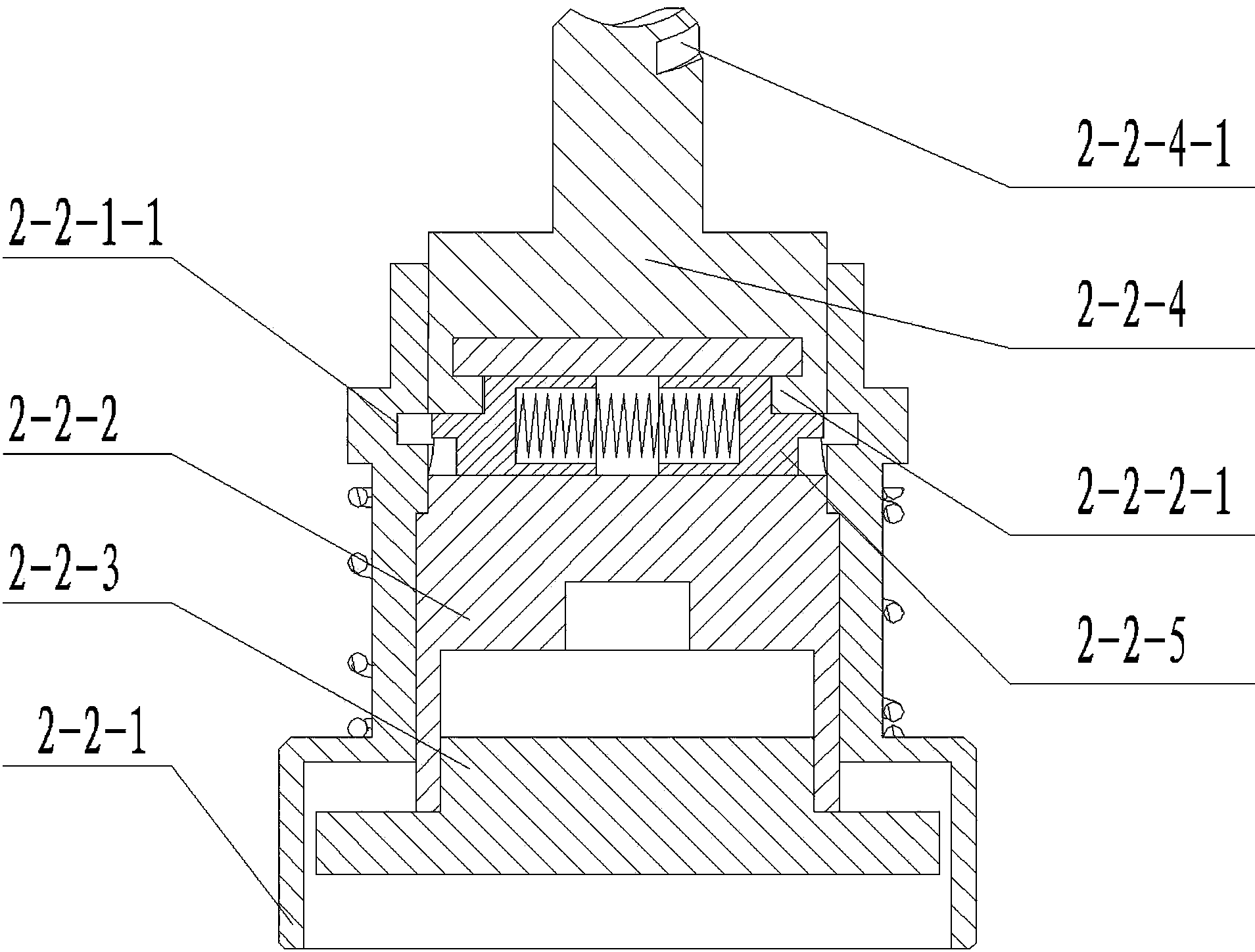

[0019] See attached figure 1 , a movement reciprocating vertical rotation transposition multi-seal stamping machine, the structure includes a frame 0, a multi-seal holding system positioned on the movement 1, a station switching drive mechanism, an ink supply mechanism and a stamping drive mechanism, and supporting control circuit, its key is: the core 1 is connected with the frame 0 by means of a linear reciprocating drive mechanism, the multi-seal holding system includes more than two seal holding chambers 2, and the center of the seal holding chamber 2 is symmetrically distributed and guided The mechanism is limited on the turntable 3 with the degree of freedom of rotation in the vertical plane, and the station conversion of the stamp holding chamber 2 and the stamp holding chamber 2 are realized by means of the station conversion drive mechanism and the linear reciprocating drive mechanism arranged on the movement 1. The stamp body assembly 2-2 is in place vertically and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com