Cofferdam type glue sticking process

A water-glue and cofferdam technology, applied in the field of cofferdam-type water-glue lamination technology, can solve problems affecting lamination efficiency and lamination machine pollution, so as to improve lamination yield, solve the problem of glue overflow, and prevent overflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The present invention will be further described below with reference to the drawings and embodiments. It can be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for ease of description, the drawings only show a part but not all of the content related to the present invention.

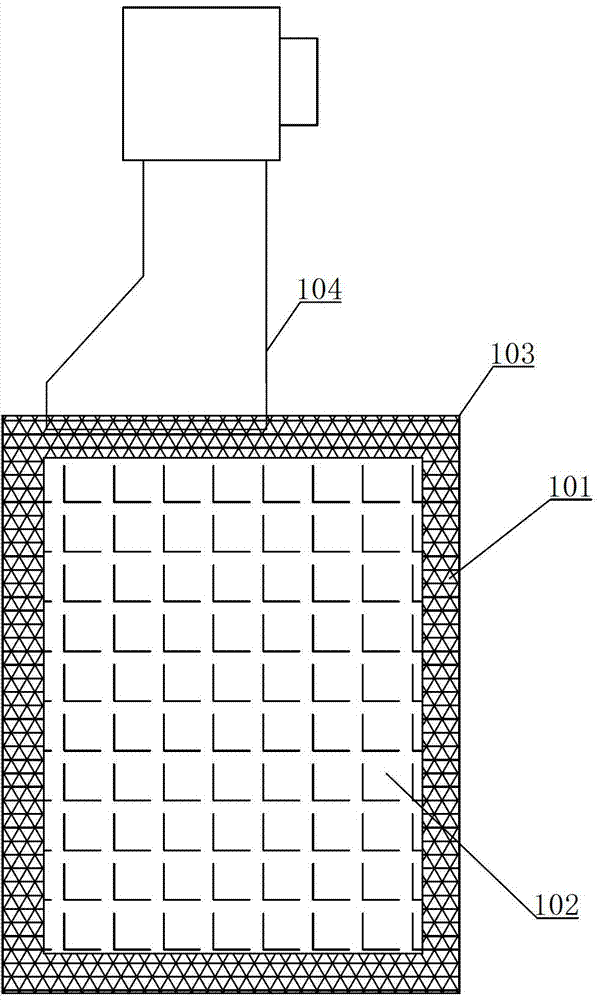

[0015] Please refer to figure 1 As shown, in this embodiment, the glue with automatic initial curing function is named glue a, the glue for laminating is named glue b, 101 is glue a dispensing area, 102 is glue b dispensing area, 103 is functional glass Sheet, 104 is a flexible circuit board.

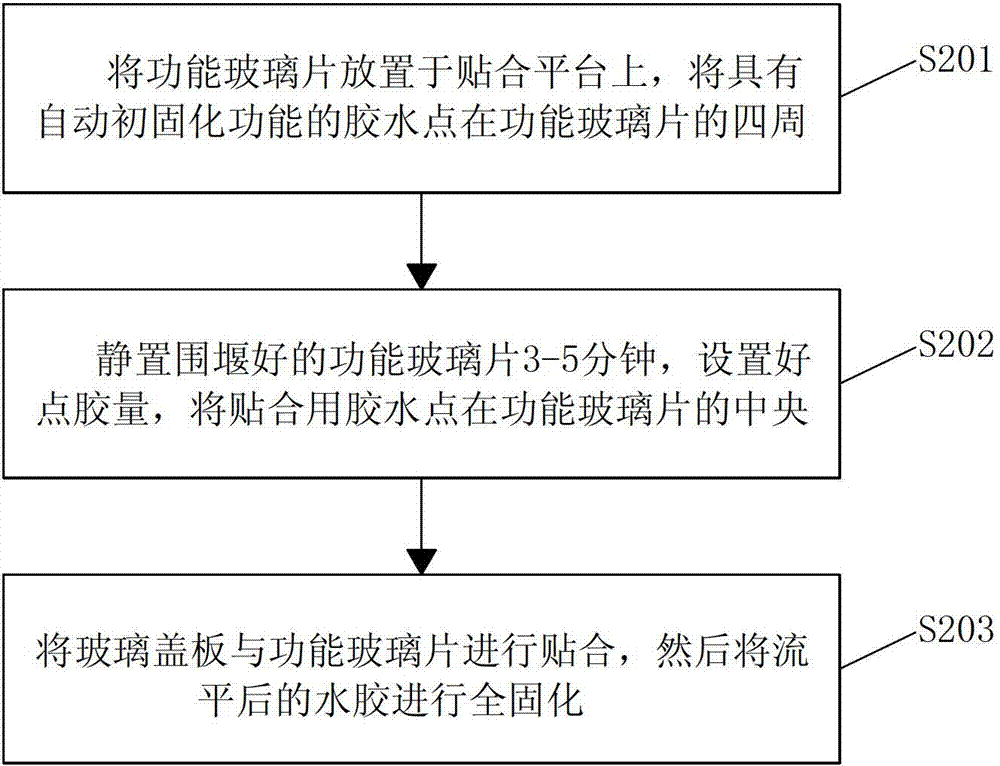

[0016] Such as figure 2 As shown, the cofferdam type water glue bonding process in this embodiment specifically includes the following steps:

[0017] Step S201: Place the bound functional glass sheet 103 on the laminating platform, set the dispensing amount, and evenly dot the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com