Inspection device for middle side wall roof side rail reinforcing plate chain connecting plate

A technology for reinforcing plates and inspection tools, applied in mechanical gap measurement, mechanical counter/curvature measurement, etc., can solve the problems of complex detection process, long cycle and low efficiency, and achieve high accuracy, short cycle and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

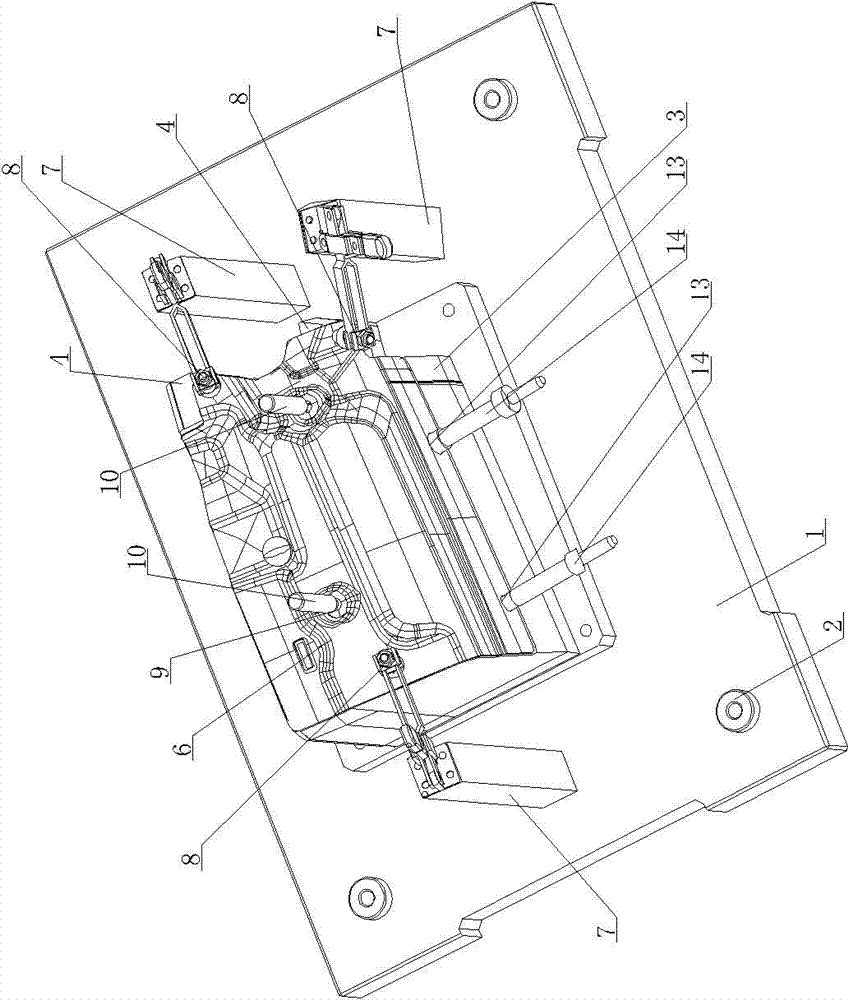

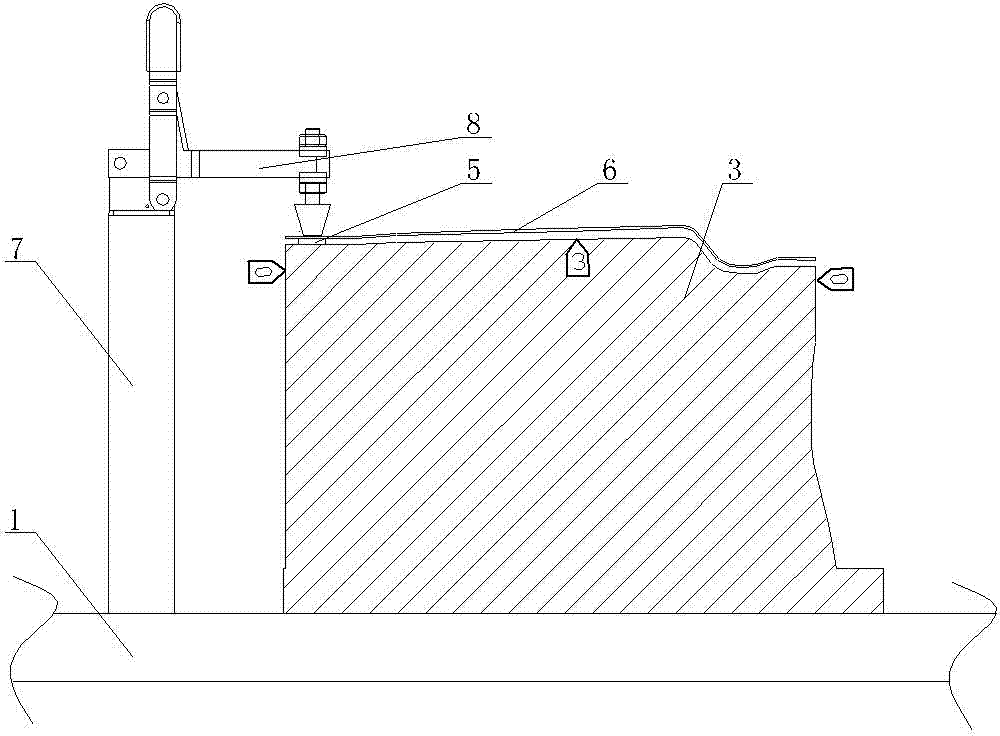

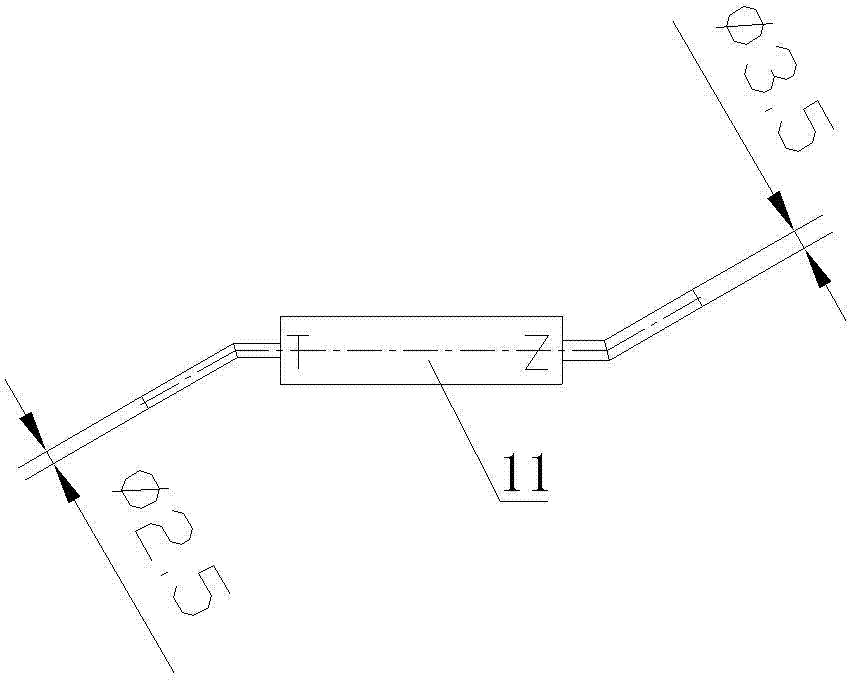

[0010] See Figure 1 ~ Figure 4 , which includes a bottom plate 1, three corner positions of the bottom plate 1 are respectively provided with reference sleeves 2, the simulation block 3 is supported on the upper end surface of the bottom plate 1, and the rear convex structure 4 of the simulation block 3 is respectively provided with convex positioning Protrusion 5, the middle position of the front end of the simulation block 3 is provided with an outwardly protruding positioning protrusion 5, and the outward protrusion distance of the positioning protrusion 5 is 3 mm. Paste the upper end surface of the positioning bump 5, the bottom plate 1 is provided with a clamp bracket 7 corresponding to the corresponding position of the positioning bump 5, each clamp bracket 7 is fastened to the bottom plate 1, the clamp bracket 7 is connected to the clamp 8, and the detection status The lower press pliers 8 correspond to the upper end surface of the link plate 6 of the middle side sill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com