Vertically-split type movable bee frame

A technology of movable nest frame and bee, which is applied in beehives, beekeeping, application and other directions, can solve the problems of vertical separation and the inability of bees to move the nest frame, and achieve the effect of simple and quick separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

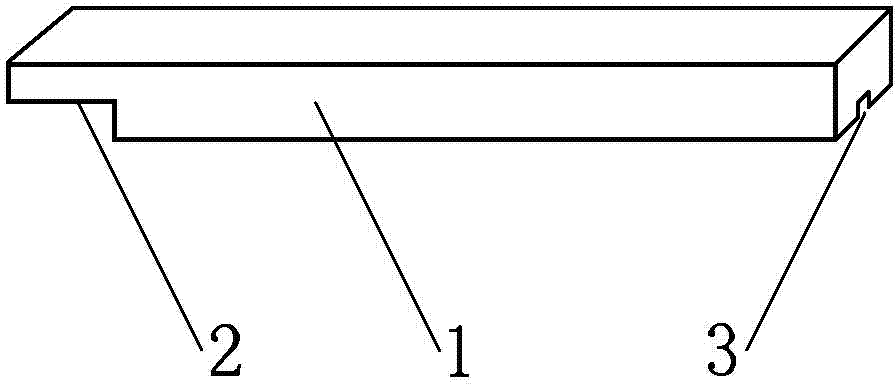

[0018] exist figure 1 Among them, use wooden materials to process 2 wooden upper beams (1) with a length of 238.5 to 241.7 mm, a width of 25 to 27 mm, and a thickness of 20 mm. One end of the wooden upper beam (1) is cut off one piece with a length of 27.5 mm. ~30mm, 25~27mm wide, 10mm thick wood, keep 27.5~30mm long, 25~27mm wide, 10mm thick side strip fixing surface (2), the center below the wooden upper beam (2) On the line, process a nest foundation embedding groove (3) with a width of 3 to 4 millimeters and a depth of 3 to 4 millimeters.

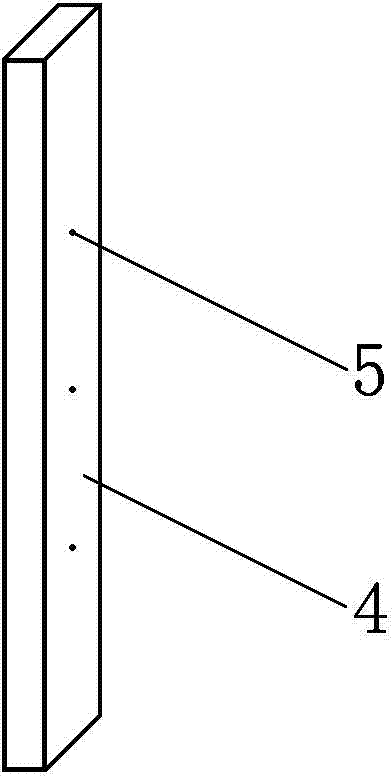

[0019] exist figure 2 Among them, use wooden materials to process 2 pieces of wooden edge strips (4) with a length of 225 mm, a width of 25-27 mm, and a thickness of 10 mm. A threading hole (5) with a diameter of 1 mm is convenient for penetrating fine metal threads.

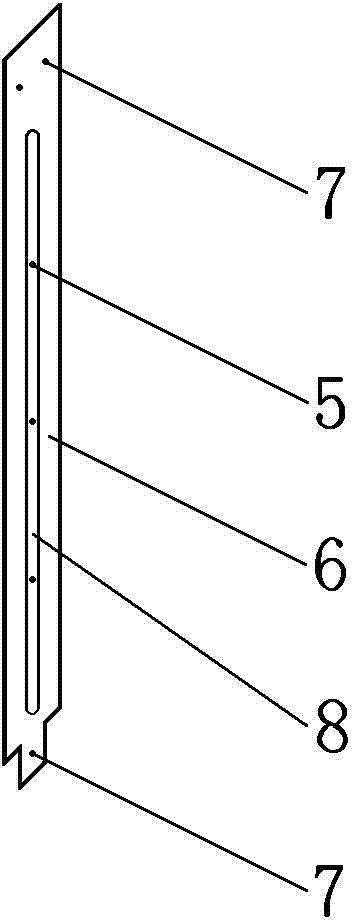

[0020] exist image 3 In the process, use a metal plate with a thickness of 0.8-1.5 mm to process 2 metal edge strips (6) with a length of 235 mm, a width of 10-27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com