Cover and method for making rolled material for cover

A manufacturing method and a technology for lids are applied in the field of manufacturing lids and rolled products for lids, which can solve the problems of many operation procedures and cumbersome work, and achieve the effect of simplifying the operation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

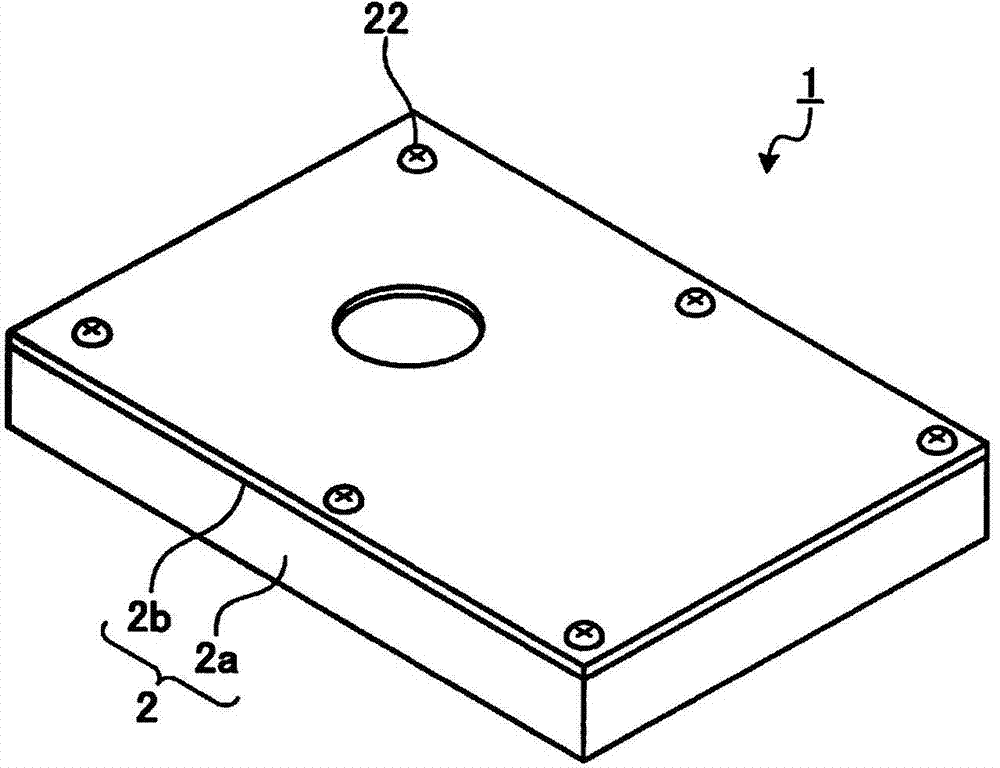

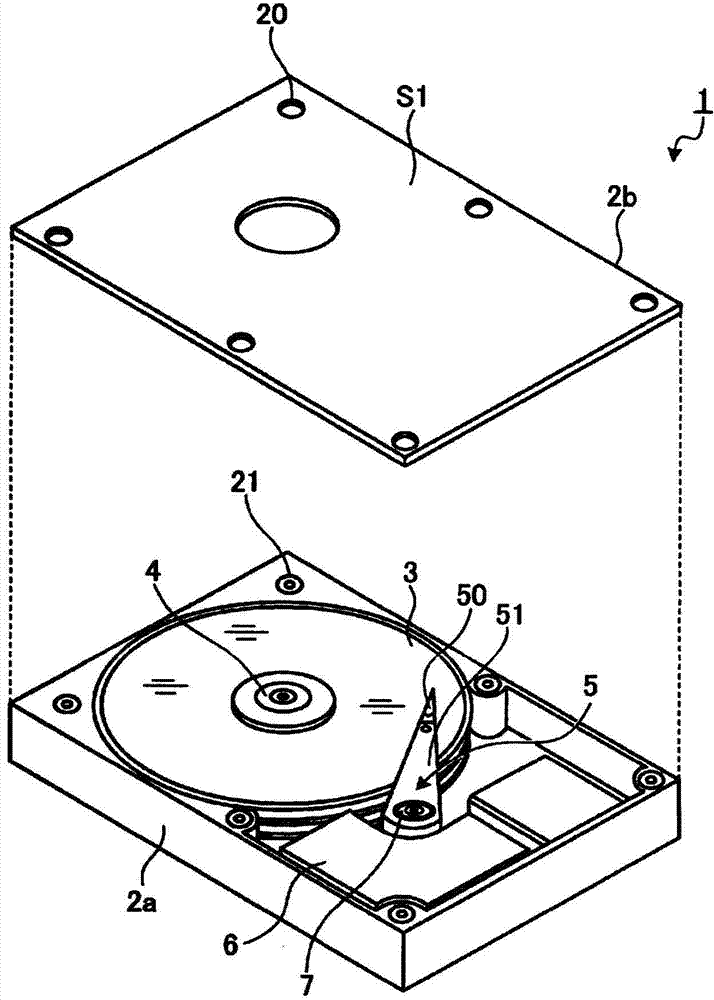

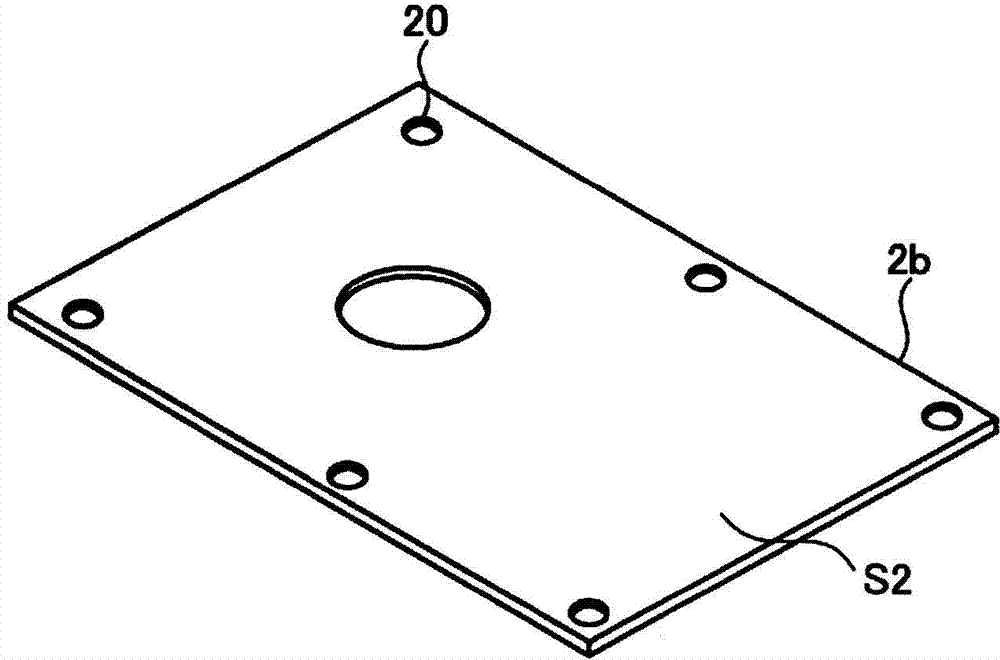

[0027] Hereinafter, modes for implementing the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited by the following embodiment. In addition, each drawing referred to in the following description merely shows shape, size, and positional relationship briefly so that the content of this invention can be understood. That is, the present invention is not limited to the shapes, sizes, and positional relationships illustrated in the drawings. In addition, in the following description, the structure of the hard disk drive which is a precision equipment is demonstrated as an example of a cover.

[0028] figure 1 It is a perspective view showing a schematic configuration of the hard disk device according to the embodiment of the present invention. in addition, figure 2 It is an exploded perspective view showing a schematic configuration of the hard disk device according to the embodiment of the present invention. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean roughness | aaaaa | aaaaa |

| Arithmetic mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com